Testing method of external permeability of fiber fabric surface and testing mold

A fiber fabric and testing method technology, applied in the direction of permeability/surface area analysis, measuring device, suspension and porous material analysis, etc., can solve the problems that have not yet formed a unified, reliable and stable testing method, achieve low production cost, prevent Experimental error, the effect of determining the ease of fluid flow fronts

Inactive Publication Date: 2010-09-01

NAT UNIV OF DEFENSE TECH

View PDF2 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, there is no standard for the test method of the out-of-plane permeability of fiber fabrics at home and abroad, that is, a unified, reliable and stable test method has not yet been formed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

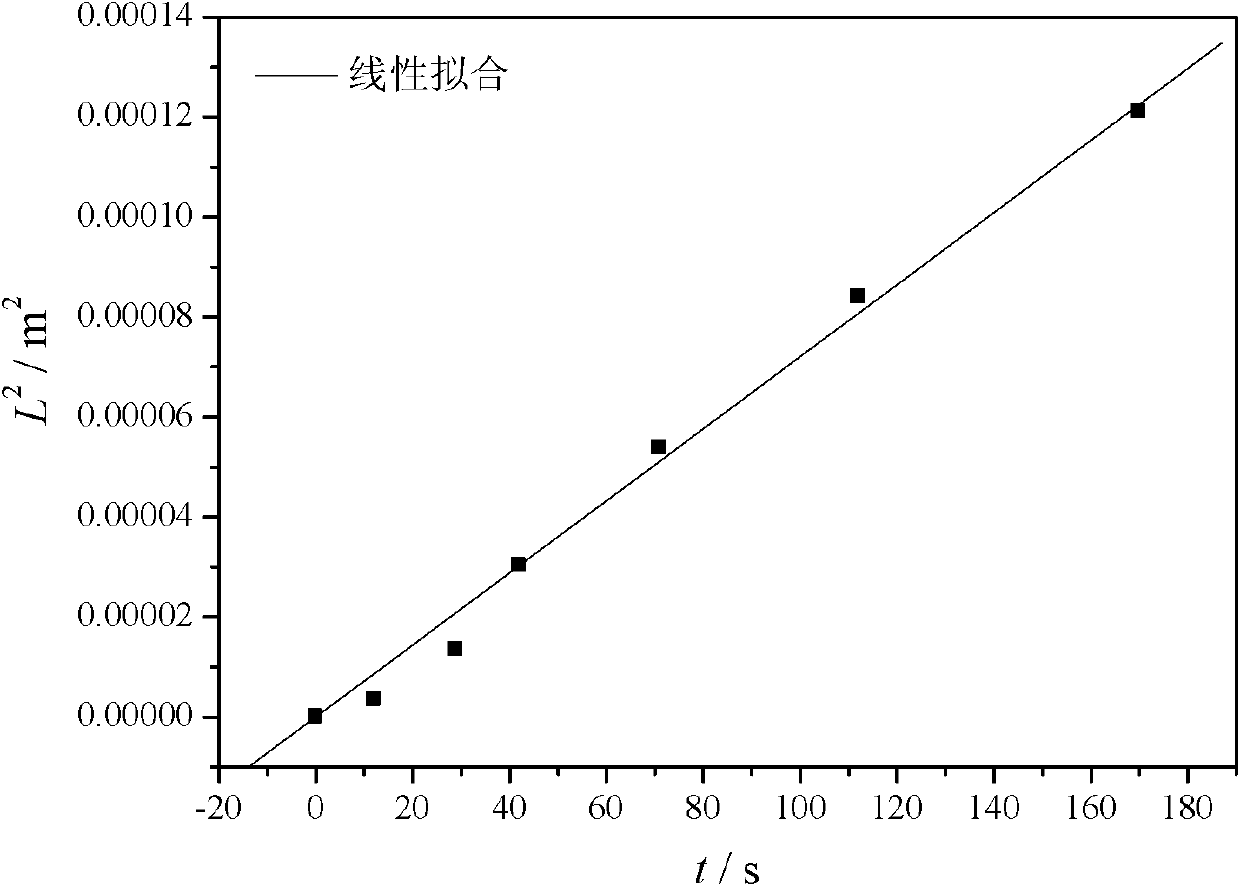

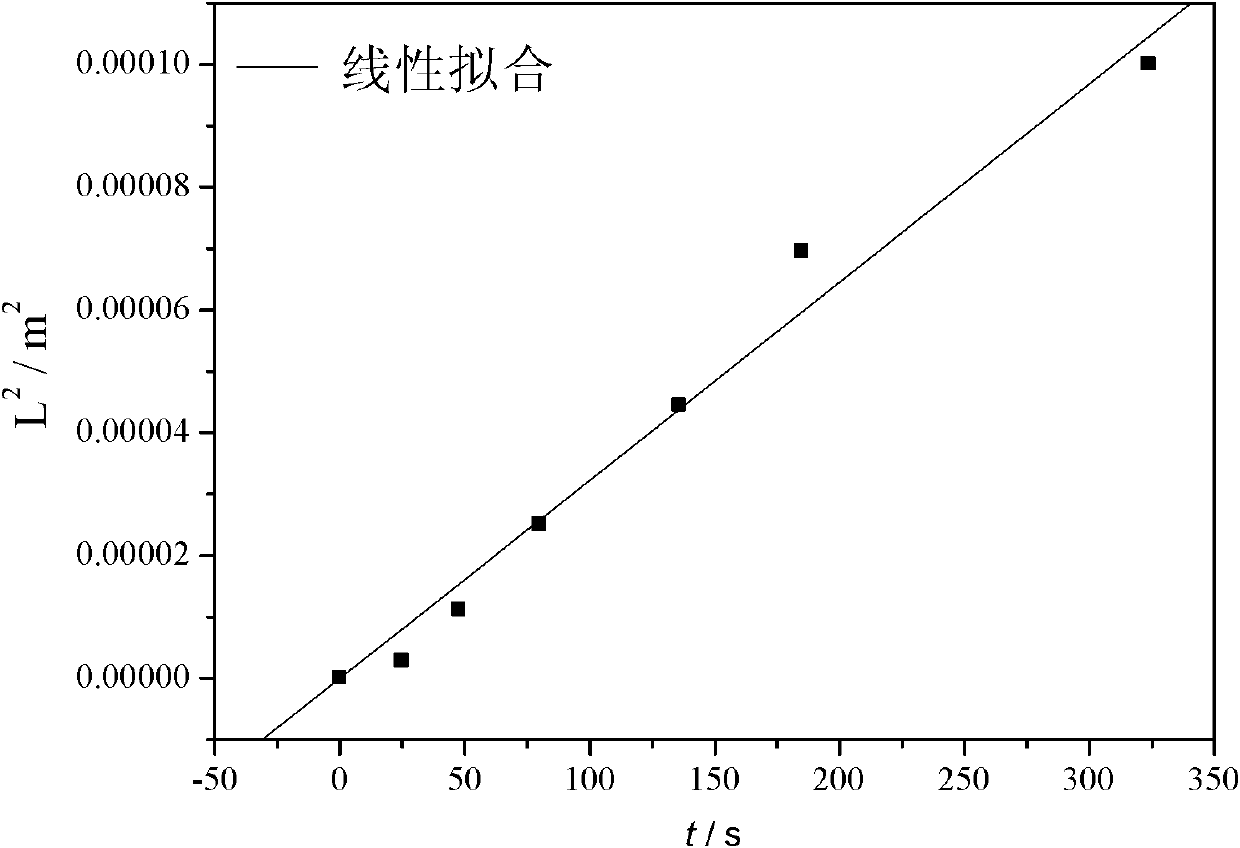

Abstract

The invention belongs to a testing method of permeability of porous materials, in particular to a testing method of external permeability of a fiber fabric surface and a testing mold. The method comprises the following steps: firstly, laying fiber fabric to be tested into n numbered steps on a mold panel, and then, sealing to form a mold cavity; carrying out vacuum pumping treatment, measuring and recording distance Ln between each step surface and the mold panel, injecting fluid for testing by utilizing vacuum negative pressure, and recording time tn for the flow front of the fluid for testing to reach each step surface; and drawing a linear relation graph of tn and the square of Ln, fitting to obtain a slope k, and then, calculating the external permeability K of the surface of the fiber fabric to be tested according to the formula. The testing mold comprises a mold panel and a storage tank, wherein the mold panel is fixedly connected above the storage tank to form a sealed containing cavity, micropores communicated with the sealed containing cavity are arranged on the mold panel, and a liquid flow channel communicated with an external liquid injecting system is arranged at the bottom of the storage tank. The invention has the advantages of simple operation, high accuracy, strong applicability, low cost, and the like.

Description

technical field The invention relates to a testing method and a testing mold for the permeability of a porous material, in particular to a testing method and a testing mold for the permeability of a fiber fabric. Background technique When using liquid forming technology to manufacture composite material components, the quality of composite material components is affected by many factors, including the properties of fiber reinforced materials, the properties of the matrix, the properties of the interface between the matrix and fiber fabrics, the operation of equipment and the formulation of process conditions Wait. Permeability is one of the characteristics of fiber reinforced materials and one of the important parameters affecting liquid molding technology. Fiber permeability can be divided into in-plane permeability and out-of-plane permeability. In-plane permeability is an indicator of the resistance a fluid experiences when passing through the plane of a fabric. The ou...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N15/08

Inventor 杨孚标杨金水彭超义肖加余曾竟成刘卓峰

Owner NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com