Film-coated lens with refraction correcting function

A film and lens technology, applied in optics, optical components, installation, etc., can solve problems such as poor comfort, single diopter, and inability to adapt to frequent changes in viewing distance, etc., to achieve low production cost, quick replacement, and obvious refractive correction effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the description of the drawings and the specific embodiments:

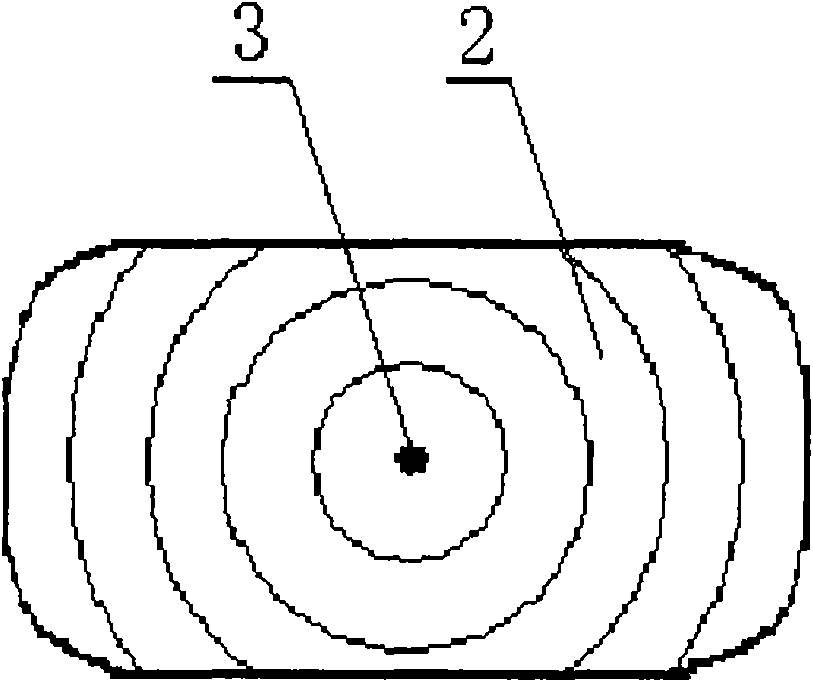

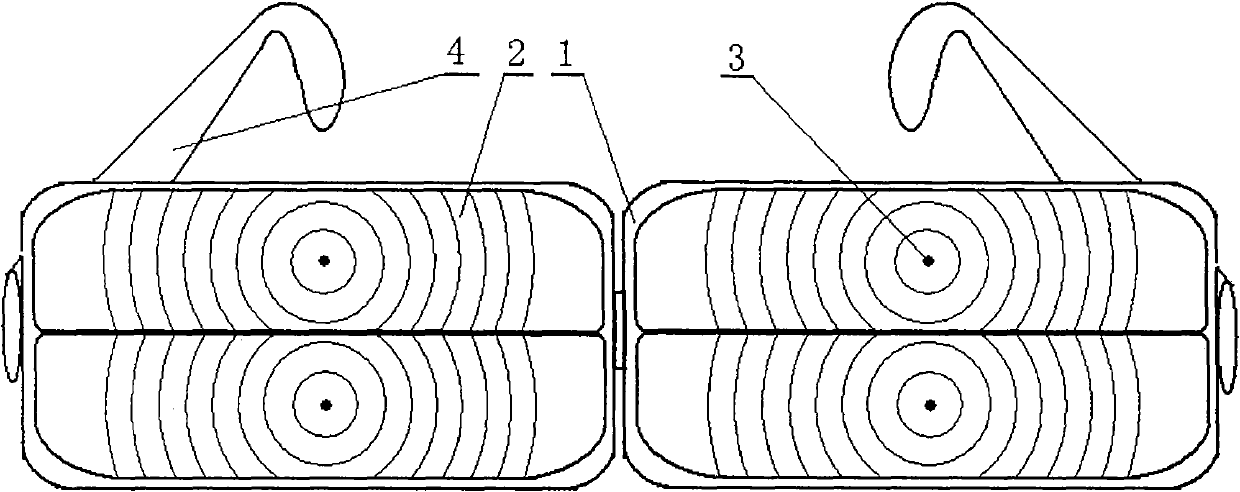

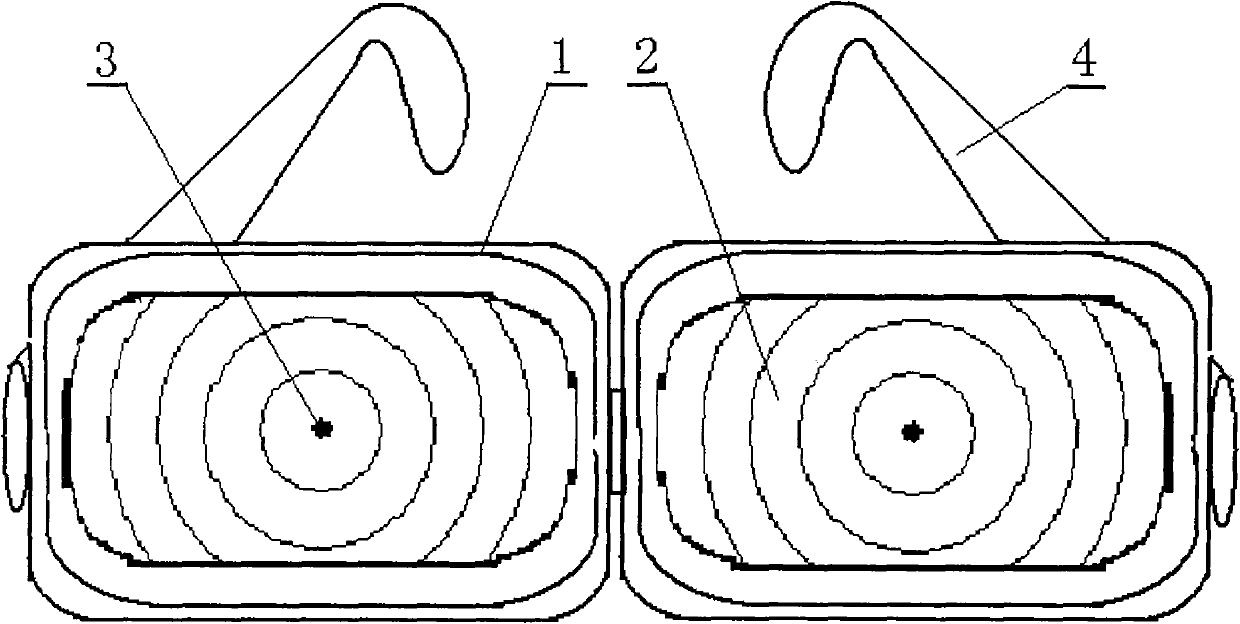

[0020] see figure 1 , figure 2 , image 3 , Figure 4 , a film lens with refractive correction function of the present invention includes a lens and a film, the lens is a flat lens 1, the film is a refractive film 2 made of soft transparent plastic, and the refractive film One side of 2 is flat and attached to the flat lens 1, and the other side of the refractive film 2 is formed with at least one concave arc surface or convex arc surface. The concave arc surface of the refractive film 2 can form a concave lens on the flat lens 1 to meet the needs of myopic patients. The convex arc surface of the refractive film 2 can form a convex lens on the flat lens 1 to meet the needs of presbyopic patients.

[0021] figure 1 The shown refractive film 2 is made of soft and transparent plastic material, and has a concave arc surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com