Rolling bearing and cage for such bearing

A rolling bearing and cage technology, applied in the field of rolling bearings, can solve problems such as high acceleration, unsuitable for high speed, fragile impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

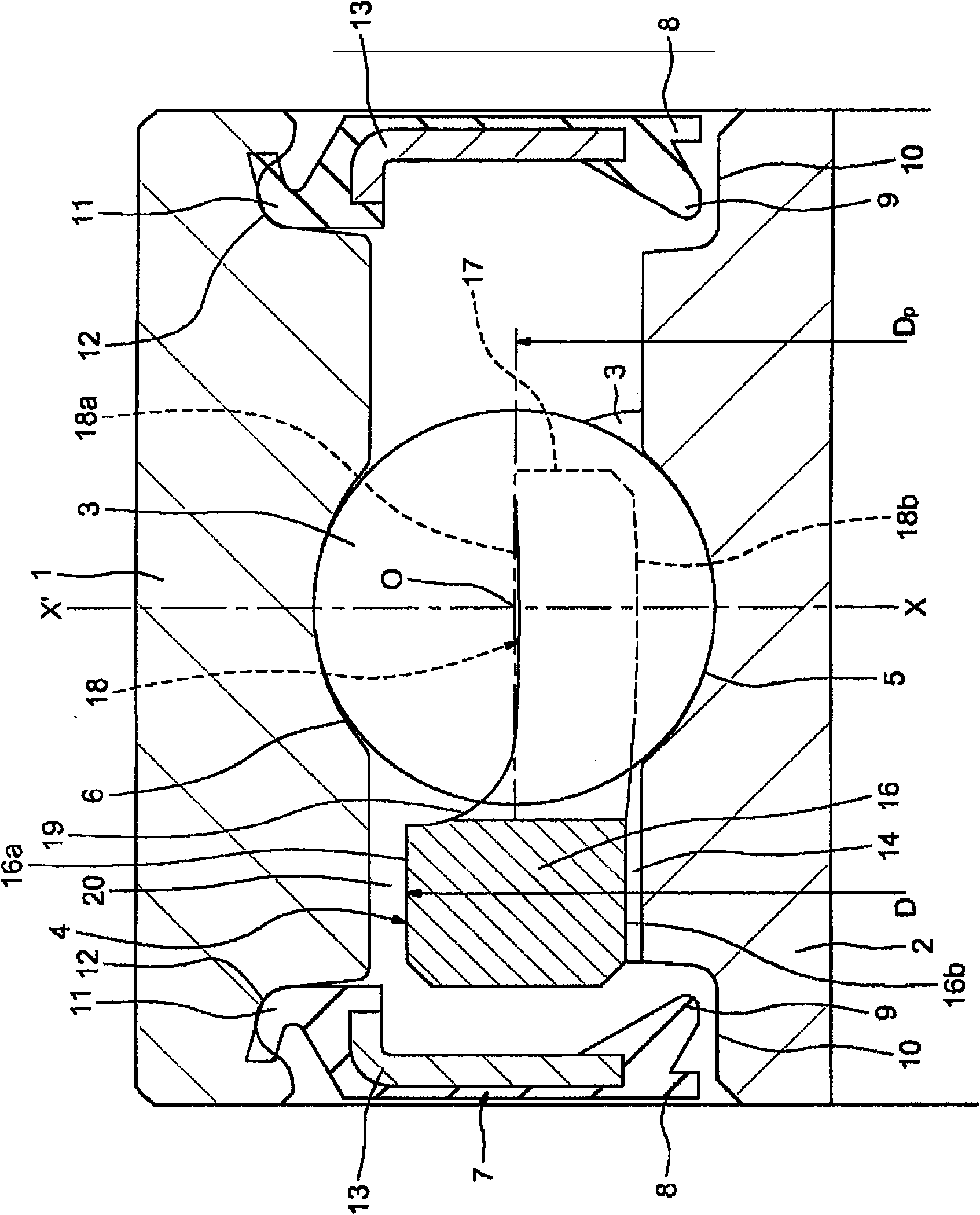

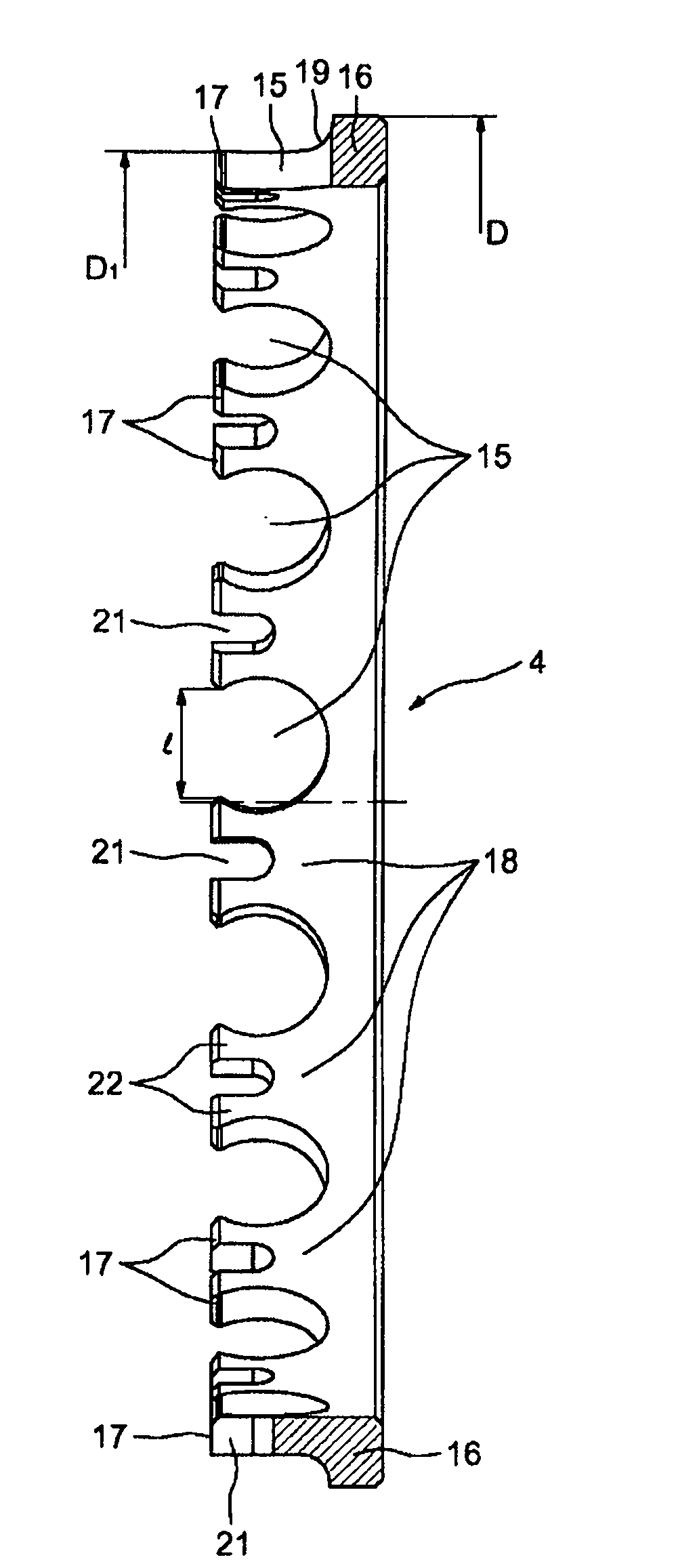

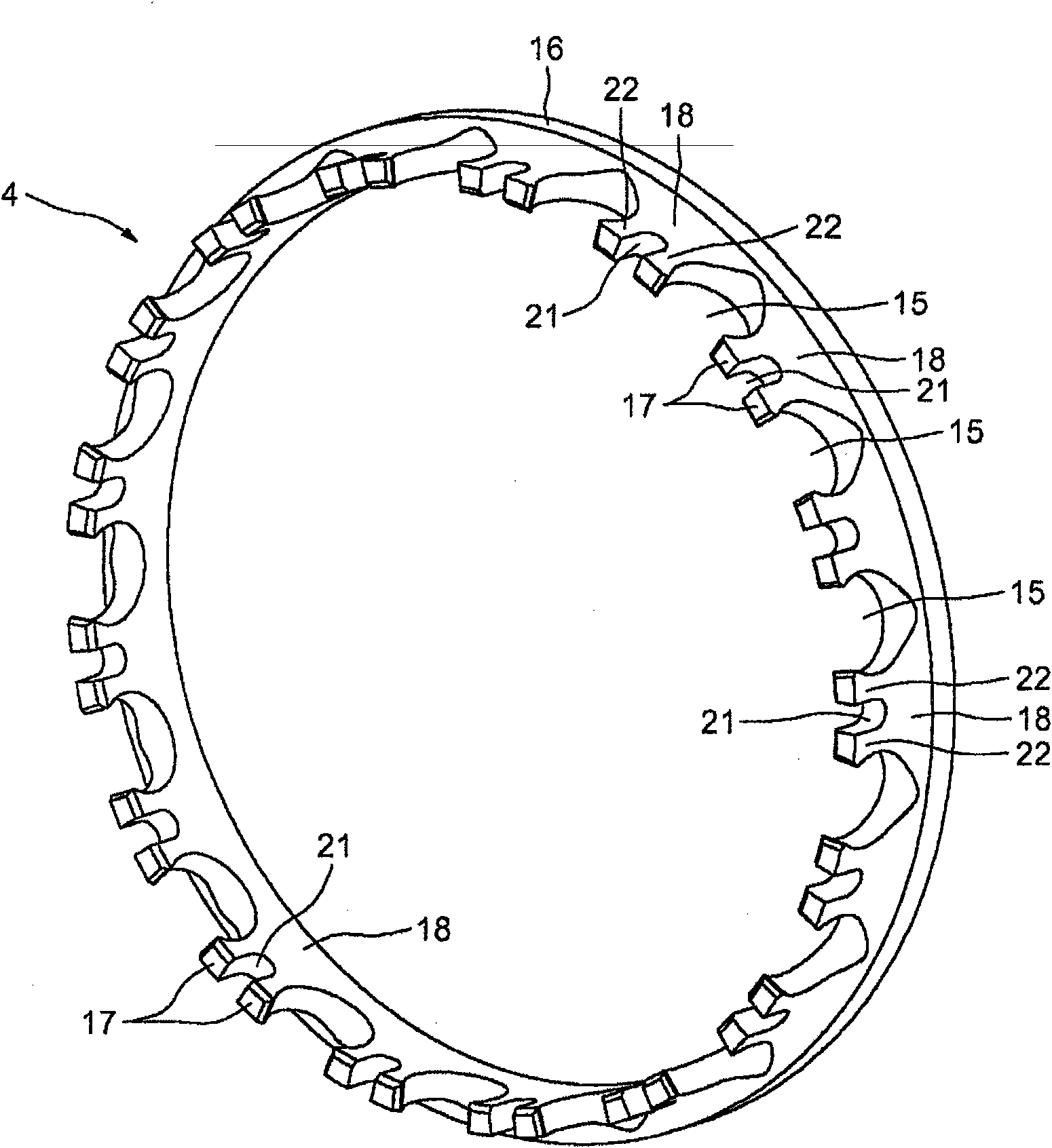

[0034] First refer to figure 1 , the rolling bearing shown, which is shown in a stationary state or rotating at a low speed, without deformation due to centrifugal force, includes an outer race 1 and an inner race 2 . Between the two races 1 , 2 is mounted a row of balls 3 held by a cage 4 of annular general shape. The balls 3 roll on ring-shaped deep bearing tracks formed in the outer surface 5 of the inner race 2 and in the bore 6 of the outer race 1 respectively. The rolling bearings are protected from external impacts by seals 7 on both sides, said seals having a generally annular plate shape with two sealing lips 8 and 9 on the bore side, which in operation form a narrow passage between them and a cylindrical surface 10 which is an integral part of the inner race 2 and whose outer diameter is smaller than that of the inner race 2 . The outer periphery of each seal 7 has a resilient edge 11 capable of snapping into a groove 12 formed in the sides of the bore of the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com