High-pressure discharge lamp

A high-pressure discharge lamp and discharge vessel technology, which is applied to parts and components of gas discharge lamps, can solve problems such as high cost, high manufacturing cost and production cost, and achieve good ignition effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

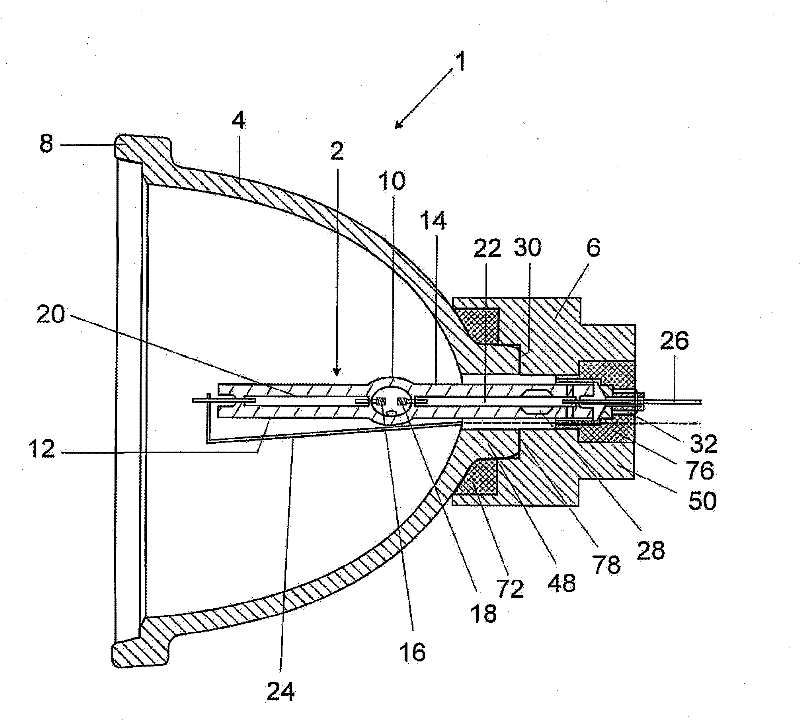

[0030] figure 1 A simplified longitudinal section through an exemplary embodiment of a high-pressure discharge lamp 1 is shown. The high-pressure discharge lamp is designed as a reflector lamp and has a burner 2 which, together with a reflector 4 , is inserted into a ceramic part 6 . The reflector 4 consists, for example, of glass and is provided with a reflective coating. A front disk or a front cover can be inserted into the front flange 8 in the direction of radiation of the lamp. The burner 2 essentially consists of an approximately centrally arranged discharge vessel 10 on which two rods 12 , 14 arranged on the axis of the reflector 4 are arranged. In the discharge vessel 10 there are two electrodes 16 , 18 spaced apart from one another and made of tungsten, for example, which are connected to each other by sealing foils 20 , 22 made of molybdenum fused into the rods 12 , 14 . The power supply lines 24, 26 are contacted. In the exemplary embodiment shown, the supply l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com