Overhead cable track and special track traveling crane thereof

A cable rail and track technology, applied in the field of special track driving, can solve the problems of reducing structure or material use efficiency, low transportation efficiency, etc., and achieve the effect of reducing the amount of demolition, simple structure and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

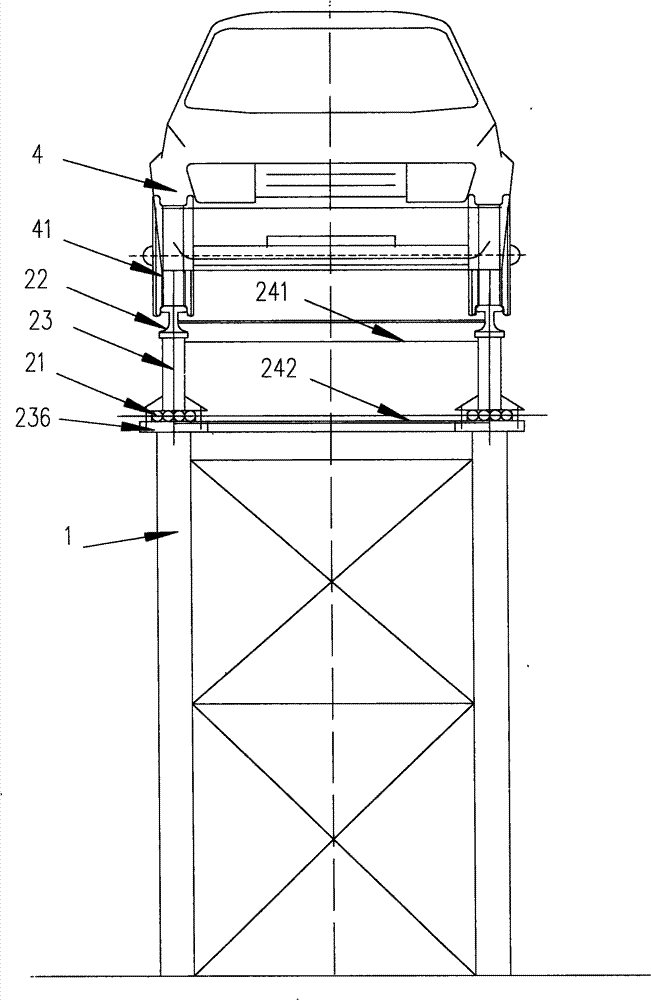

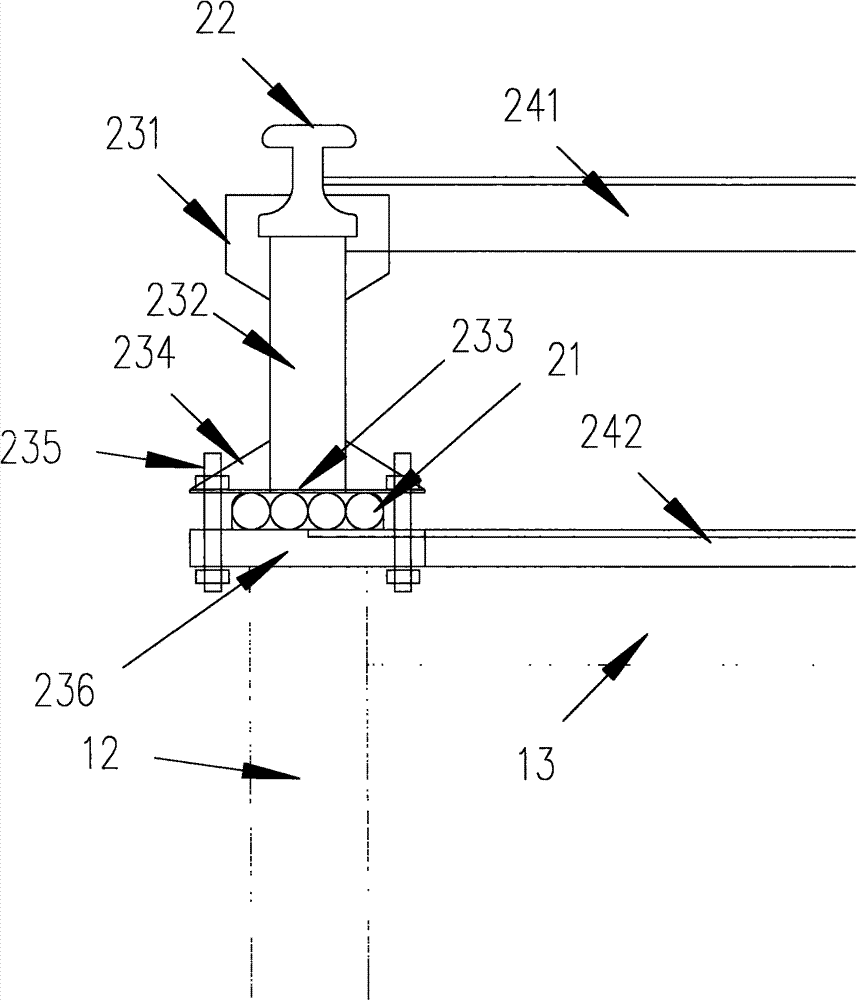

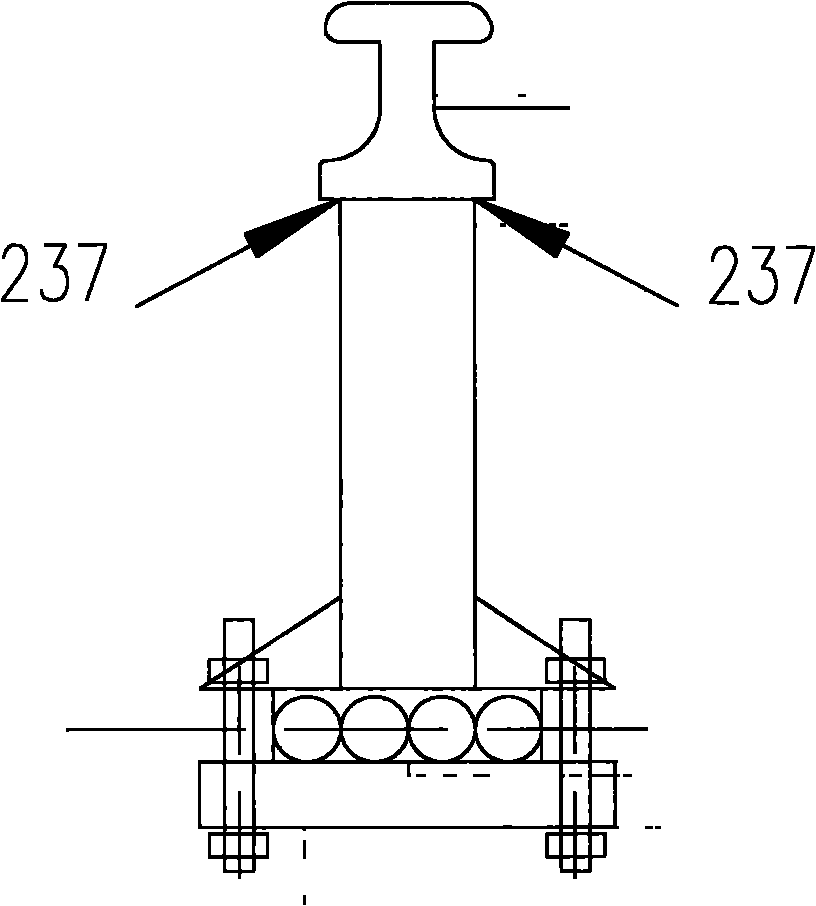

[0025] like Figure 1a to Figure 1d As shown, the cable rail elevated of the present invention has no common bridge platform, and the cable rail elevated is composed of a lower supporting system 1 and an upper cable rail platform 2 . The lower support system is composed of a number of longitudinally spaced steel structures or supports made of reinforced concrete. Each support is fixed to the ground foundation and the cable rail platform is elevated. A span unit is formed between two adjacent support columns. The cable rail platform 2 is a transportation platform composed of the upper track 22 and the lower prestressed string cable 21. The track and the string cable are connected by a number of vertical support rods 23 to realize the pre-camber of the cable rail platform, and are supported by a number of lateral supports. Rod 24 connects the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com