Clamping plate automatic temporary storage mechanism and clamping plate access method

A temporary storage mechanism and card board technology, which is applied in the stacking, transportation and packaging of objects, and the destacking of objects, etc., can solve the problem of reducing the utilization rate of the effective area of the factory building, inefficient stacking card boards manually, and occupying the space used in the factory building. and other problems, to achieve the effect of high labor costs, saving labor costs, and saving plant floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

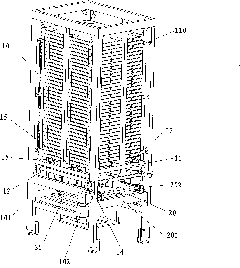

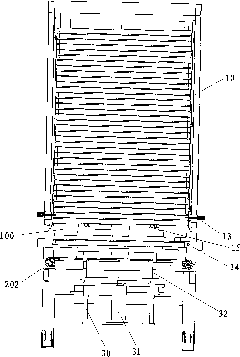

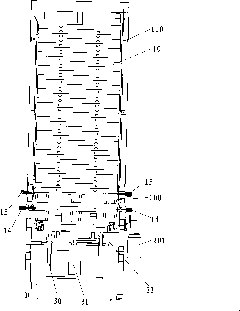

[0028] see figure 1 as well as figure 2 The pallet automatic temporary storage mechanism of the present invention includes a temporary storage rack 10 in the shape of a rectangular parallelepiped frame, a transmission raceway 20 located in the middle of the temporary storage rack 10 , and a jacking mechanism 30 located below the transmission raceway 20 .

[0029] The temporary storage rack 10 includes four frame faces that are first connected, and every two frame faces that are arranged in parallel form a group of frame faces (not labeled in the figure), and the two groups of frame faces are perpendicular to each other. The transmission raceway 20 is arranged between the two sets of frame faces, the middle part of each frame face of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com