Anti-hardening, anti-freeze and anti-locking method and device for silo buried revolving spiral

An anti-caking and helical technology is applied in the field of anti-caking, freezing, jamming and jamming devices of the above-mentioned buried rotary screw, which can solve the problems of difficulty in unloading and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

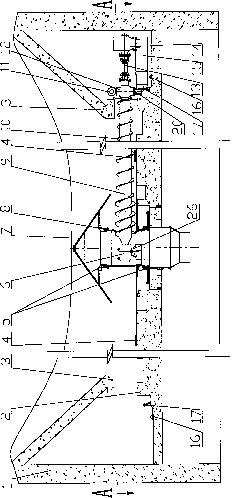

[0049] The structure of the silo buried rotary spiral anti-hardening, freezing and jamming process is as follows: figure 1 As shown, it includes a central rotary discharge cylinder 8 arranged at the center of the silo bottom plate 2 . The lower part of the central rotary discharge barrel 8 is connected to the silo bottom plate 2 through the slewing support 5, and the upper part is connected to the circular protective cap 7 through the slewing support 5, so that it can freely move between the silo bottom plate 2 and the circular protective cap 7. rotate. The static accumulation angle of the material formed by the circular protective cap 7 is sufficient to prevent the material from entering the upper and lower slewing bearings.

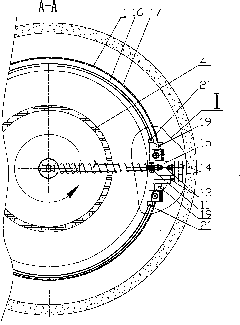

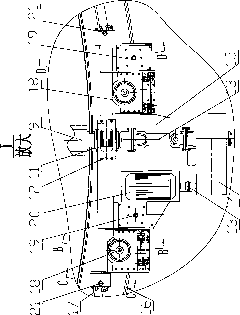

[0050] At the outer end of the silo bottom plate 2, an annular rotary track 16, 17 with the silo center as the center of the circle is installed, such as figure 2 , 4 shown. The rails 16,17 are covered by an umbrella-shaped protective eaves 3 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com