Low-uncertainty stray loss test system of motor

A technology of stray loss and test system, applied in the direction of motor generator test, etc., to achieve the effect of high test accuracy, convenient operation and simple test device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below with specific embodiment, the present invention is further elaborated:

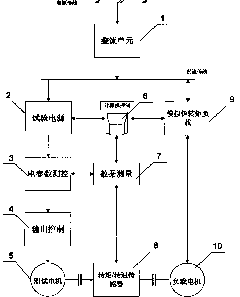

[0024] See attached figure 1 , the present invention includes: rectification unit 1, test power supply 2, simulated constant torque load 9, electrical parameter measurement and control 3, output control 4, computer control 6, data measurement 7, torque / speed sensor 8, test motor 5 and load motor 10. The AC mains is connected to the test power supply 2 and the simulated constant torque load 9 respectively after bridge rectification of the rectification unit 1; the test power supply 2 modulates the direct current into a static alternating current with variable frequency and then communicates with the electric parameter measurement and control 3, output control 4 and The test motor is connected to 5; the simulated constant torque load 9 is connected to the load motor 10 after the direct current is modulated into a controllable power supply of the constant torque load, and the output of the load ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com