Composite steel claded mill liner

A composite lining and mill technology, applied in the directions of transportation and packaging, grain processing, thin material processing, etc., can solve the problems of long time for fixing and dismantling, heavy weight of individual linings, and large size of fixed parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

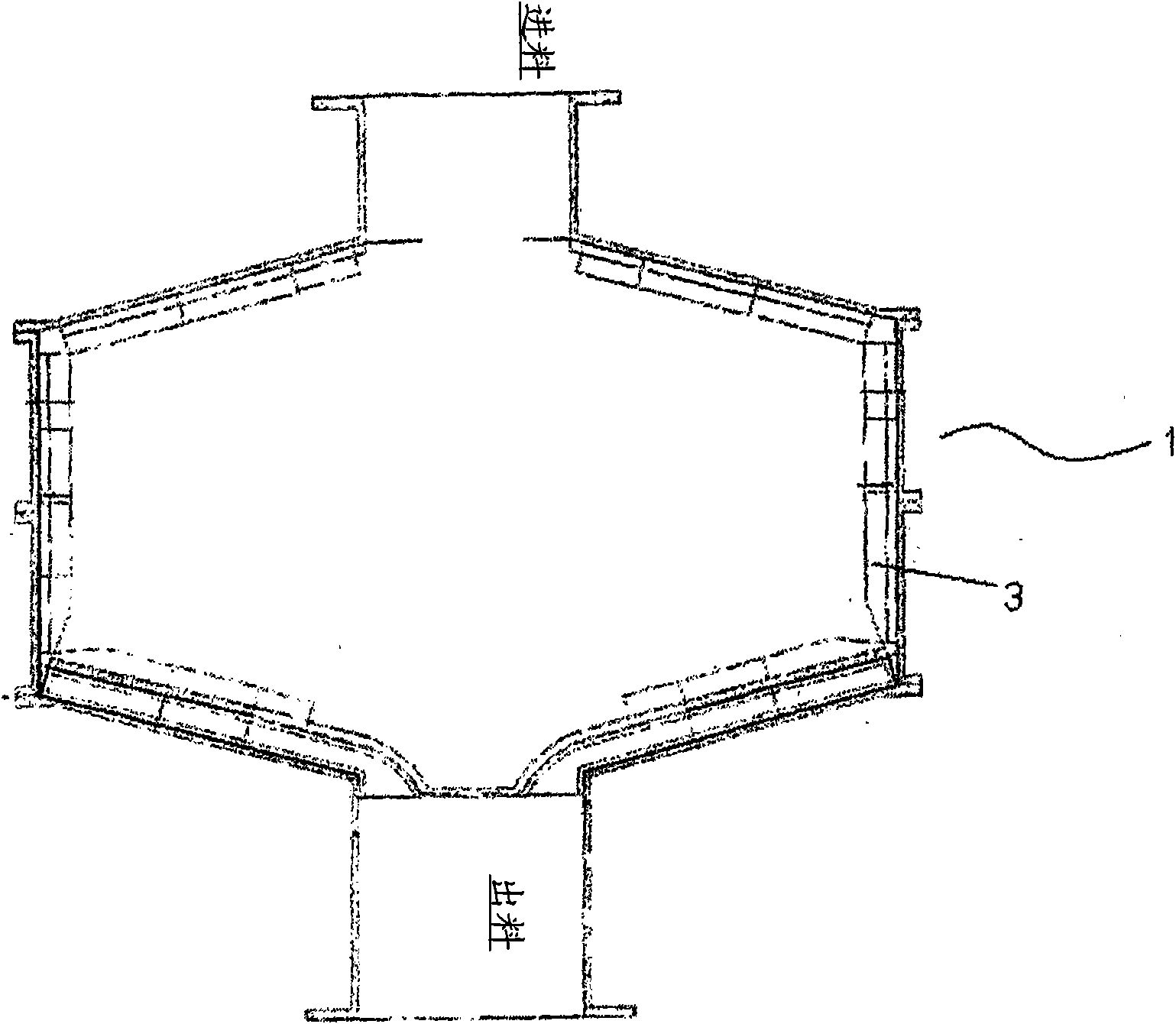

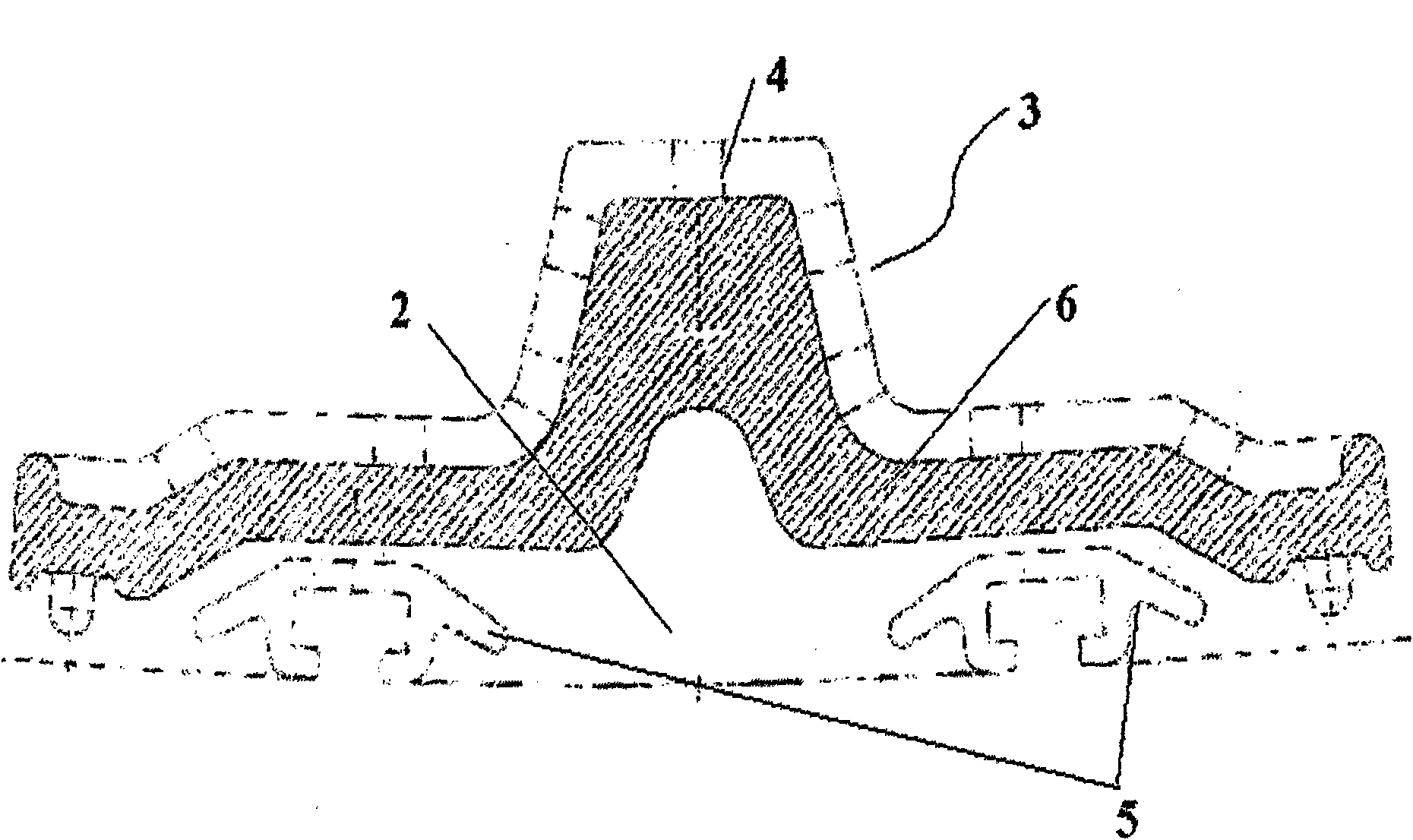

[0030] According to the present invention, disclosed as figure 1 Symmetrically distributed soft rubber backing of the composite lining system shown. The inner wall of the housing of the mill 1 was retrofitted with a rubber-lined composite mill liner 3 . The liner has an upper layer made of cast steel. An example of a liner of the present invention is a layer of chromium molybdenum cast steel combined with a rubber backing layer. Natural rubber may be used to manufacture the rubber layer. These two layers form an integrated system of rubber backing and composite lining. The two layers are bonded together by heat vulcanization during transfer moulding.

[0031] The liner of the present invention does away with the existing thinking of securing the lifting rod to the shell. Instead, the liner of the present invention is a single profile of rod and plate. Thus, independent of any number of holes available in a row, individual profiles can be designed depending only on the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com