Assembled road structure and construction process thereof

A technology of road structure and construction technology, applied in the municipal field, can solve problems such as increased maintenance and construction costs, easy cracking of joints, weather effects, etc., achieve simple and convenient transformation and maintenance, increase joint strength, and prevent road deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be further described below in conjunction with specific embodiments and accompanying drawings.

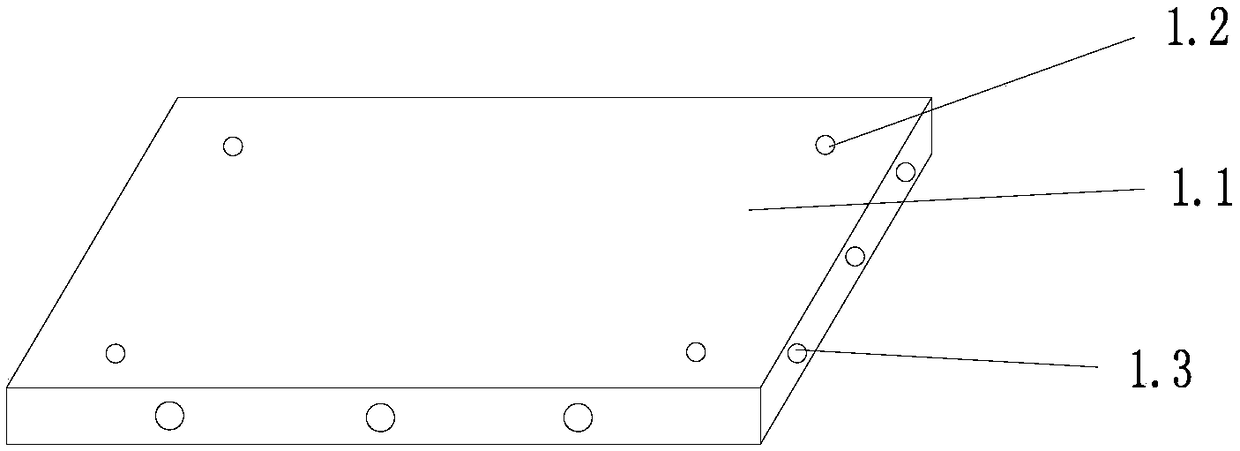

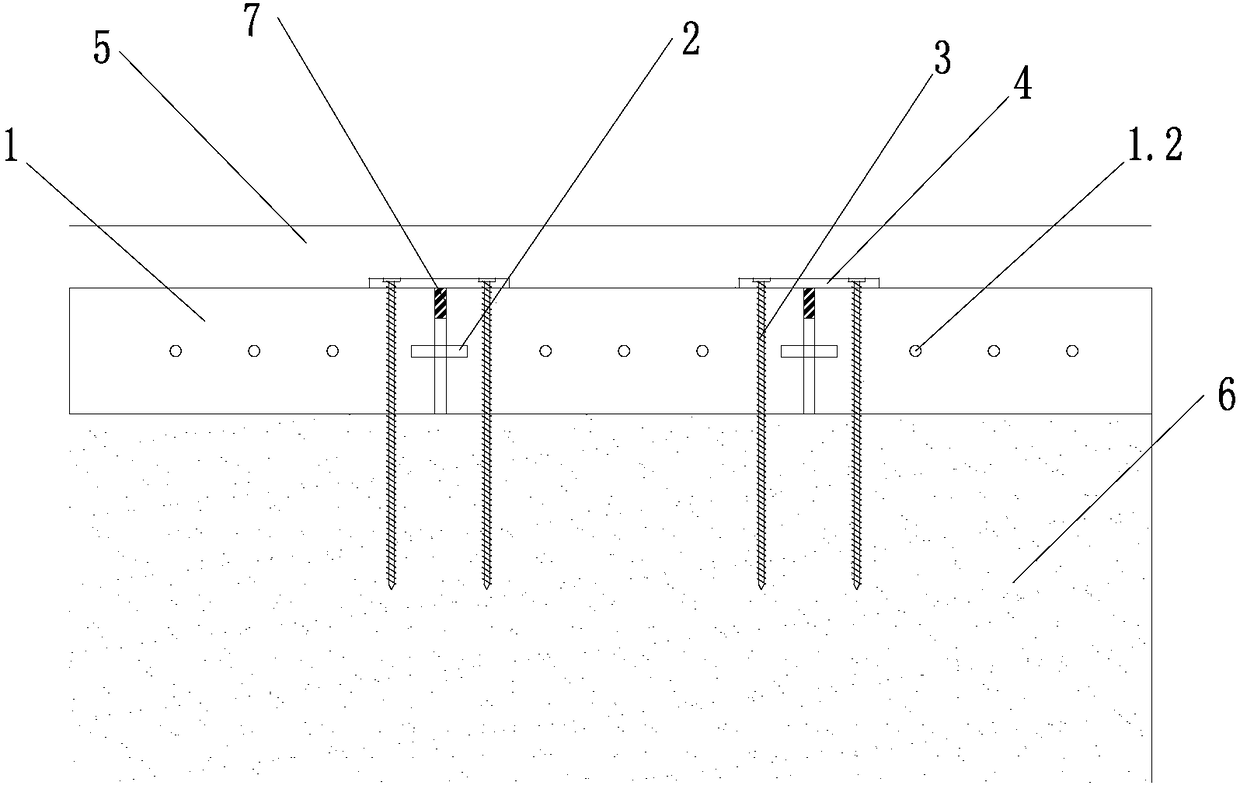

[0018] As shown in the figure, the fabricated road structure includes a roadbed 6 , a reinforced concrete slab 1 and an asphalt pavement 5 . The four corners of the reinforced concrete slab 1 are provided with paired perforations 1.2, and the sides of the reinforced concrete slab 1 are provided with connecting rod grooves 1.3. A steel plate 4 is placed on the adjacent reinforced concrete slab 1, and the riveting rod 3 passes through the steel plate 4 and the pair of perforations 1.2 to fix the reinforced concrete slab 1 on the roadbed 6. The asphalt pavement 5 is laid on the surface of the reinforced concrete slab 1 and bonded to each other by adhesive layer oil.

[0019] In order to ensure the reliability of the structure, the connecting rod groove 1.3 and the pair of perforations 1.2 are provided with internal threads, and the two ends of the conductive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com