Pneumatic drying device

A technology of airflow drying and airflow, which is applied in the preparation of tobacco, application, tobacco, etc., can solve the problem of high manufacturing cost and achieve the effect of saving pipe materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the present invention, the present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited to the scope described in the examples.

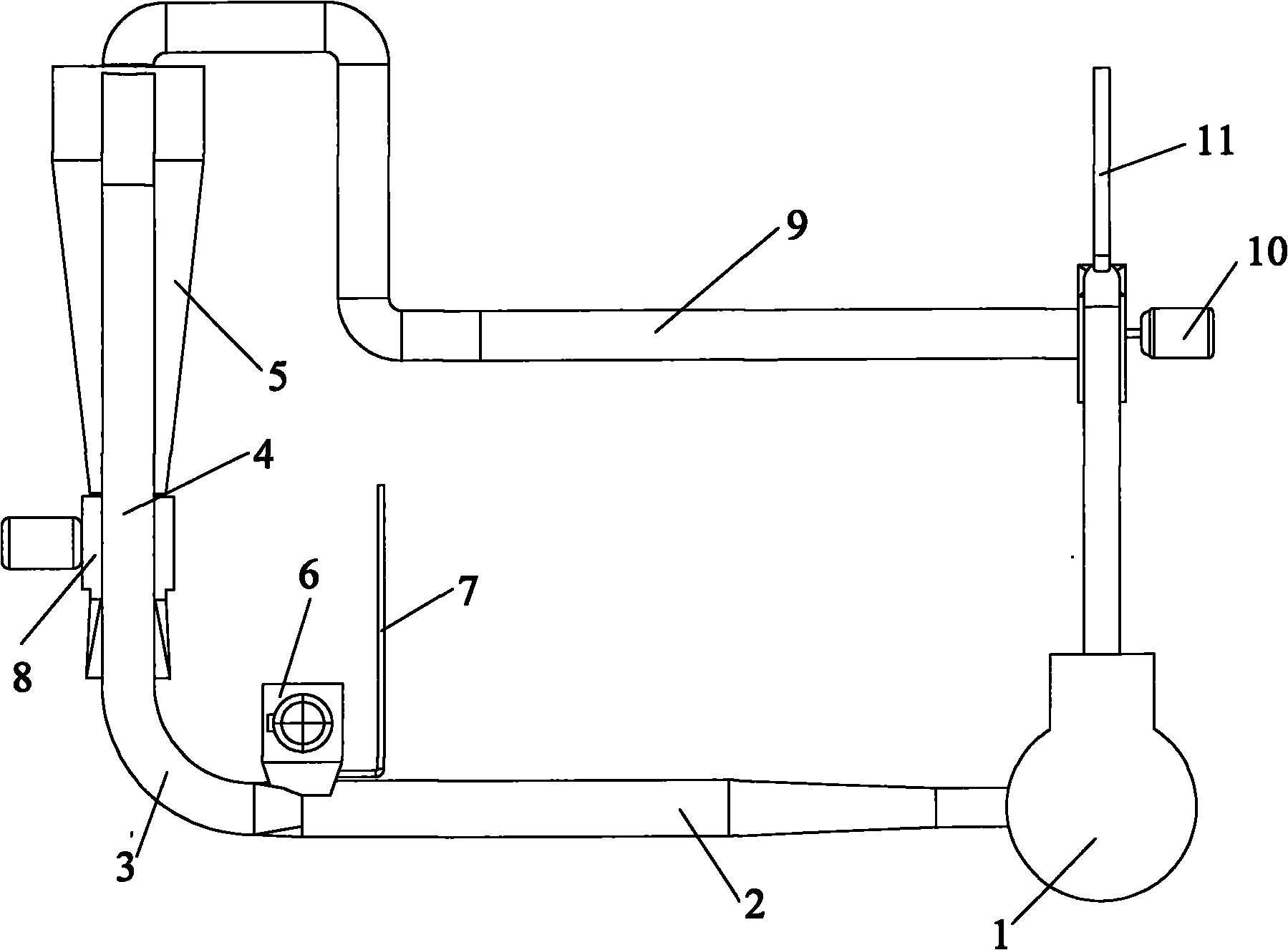

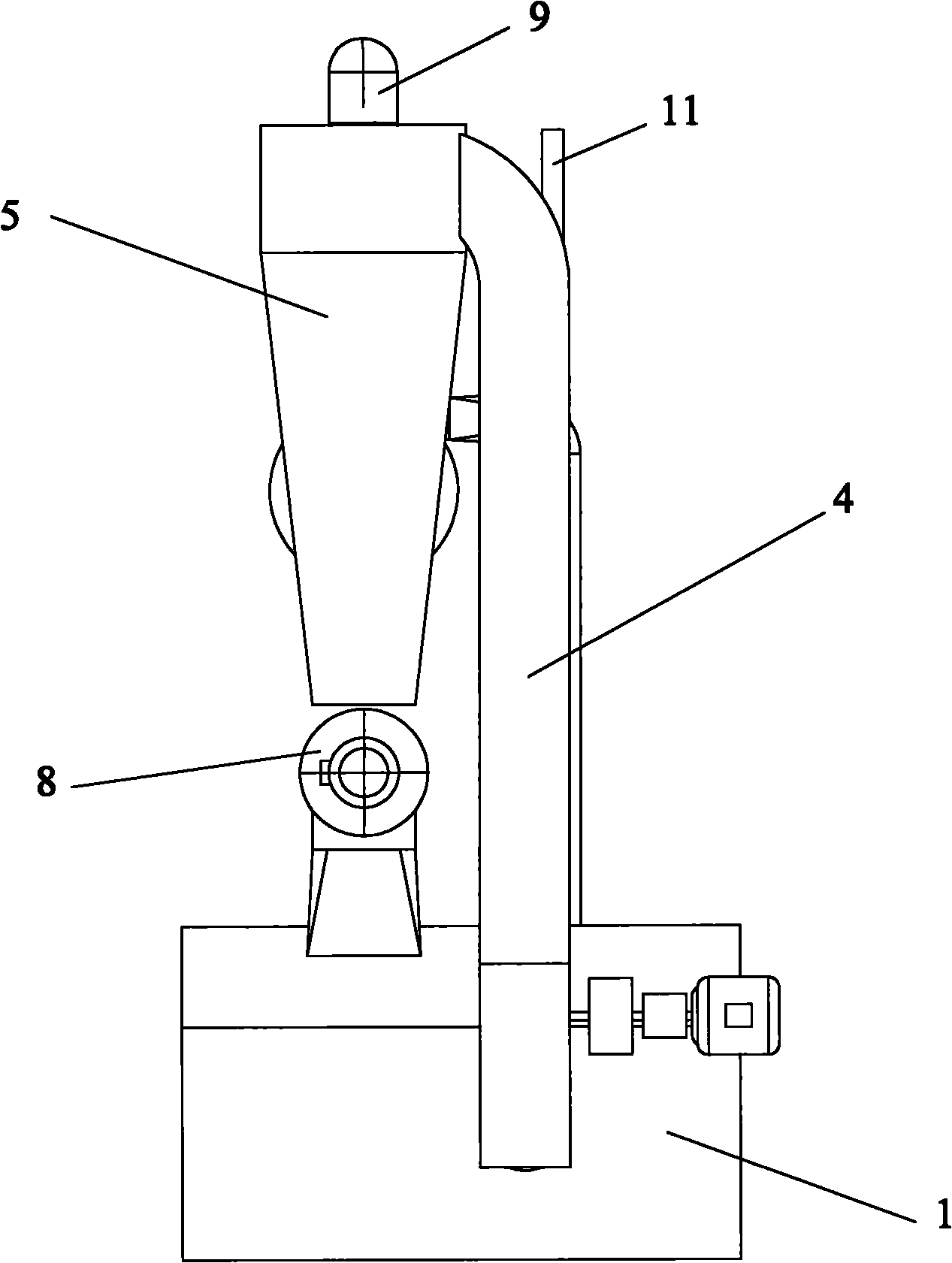

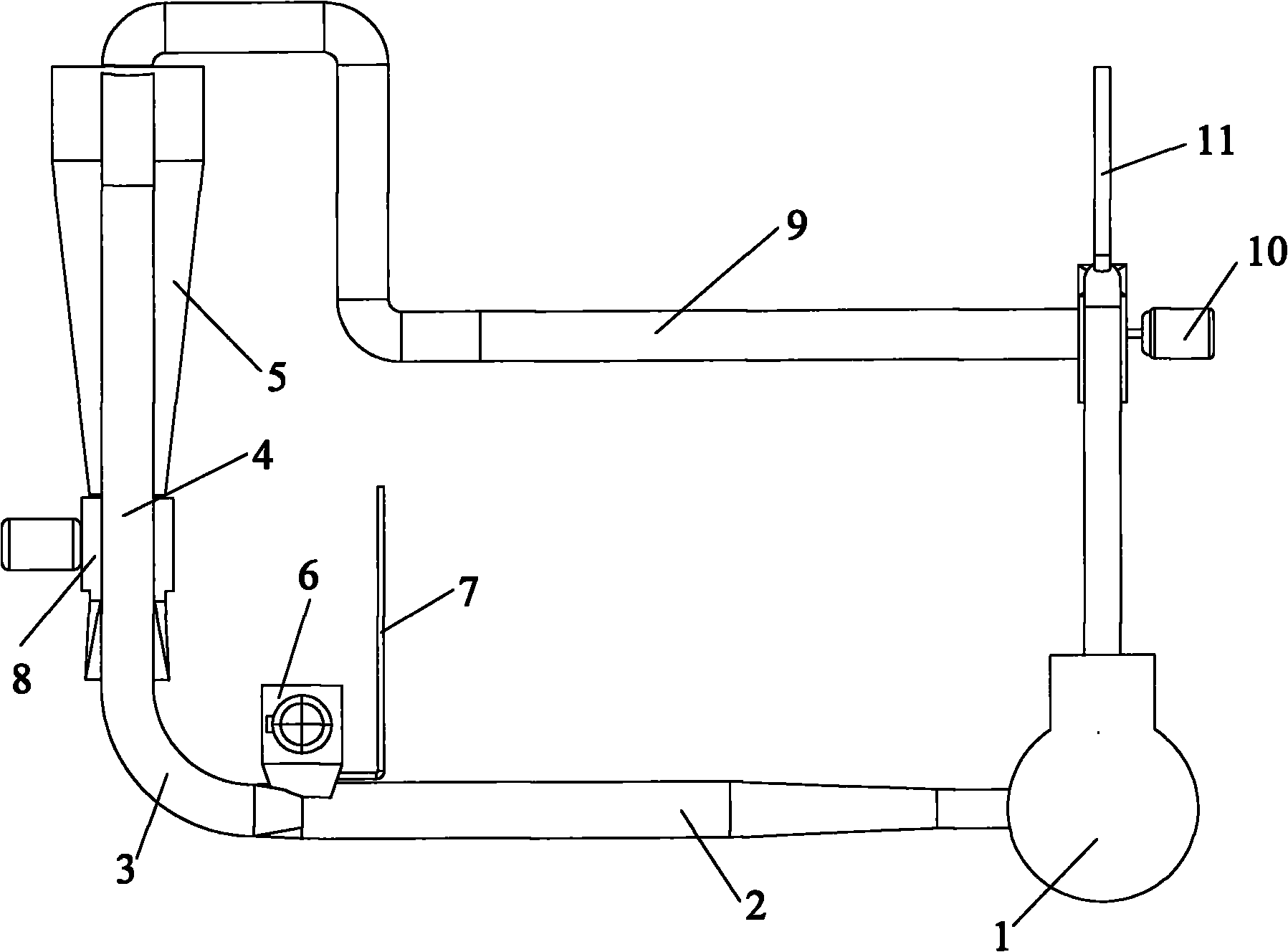

[0030] Such as figure 1 As shown, the airflow drying device of the present invention includes a combustion furnace 1, one end of the combustion furnace 1 is connected with a horizontal drying pipe 2, and the horizontal drying pipe 2 is connected with a vertical drying riser 4 through an elbow 3, and the vertical drying The riser pipe 4 is connected to a cyclone separator 5 . The hot air generated in the combustion furnace 1 is blown into the horizontal drying pipe 2 to heat and dry the shredded tobacco entering the horizontal drying pipe 2 . Wherein, the combustion furnace 1 can also be replaced by other airflow heaters. The elbow 3 is an arc-shaped connecting portion.

[0031] A feed pipe 6 is arranged on the side of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com