Automatic screw mounting machine

A technology of mounting machine and mounting mechanism, which is applied in the field of light-electricity-gas, can solve the problems that cannot be widely used, affect production efficiency, and low work efficiency, and achieve the effects of reasonable structure, improved efficiency, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

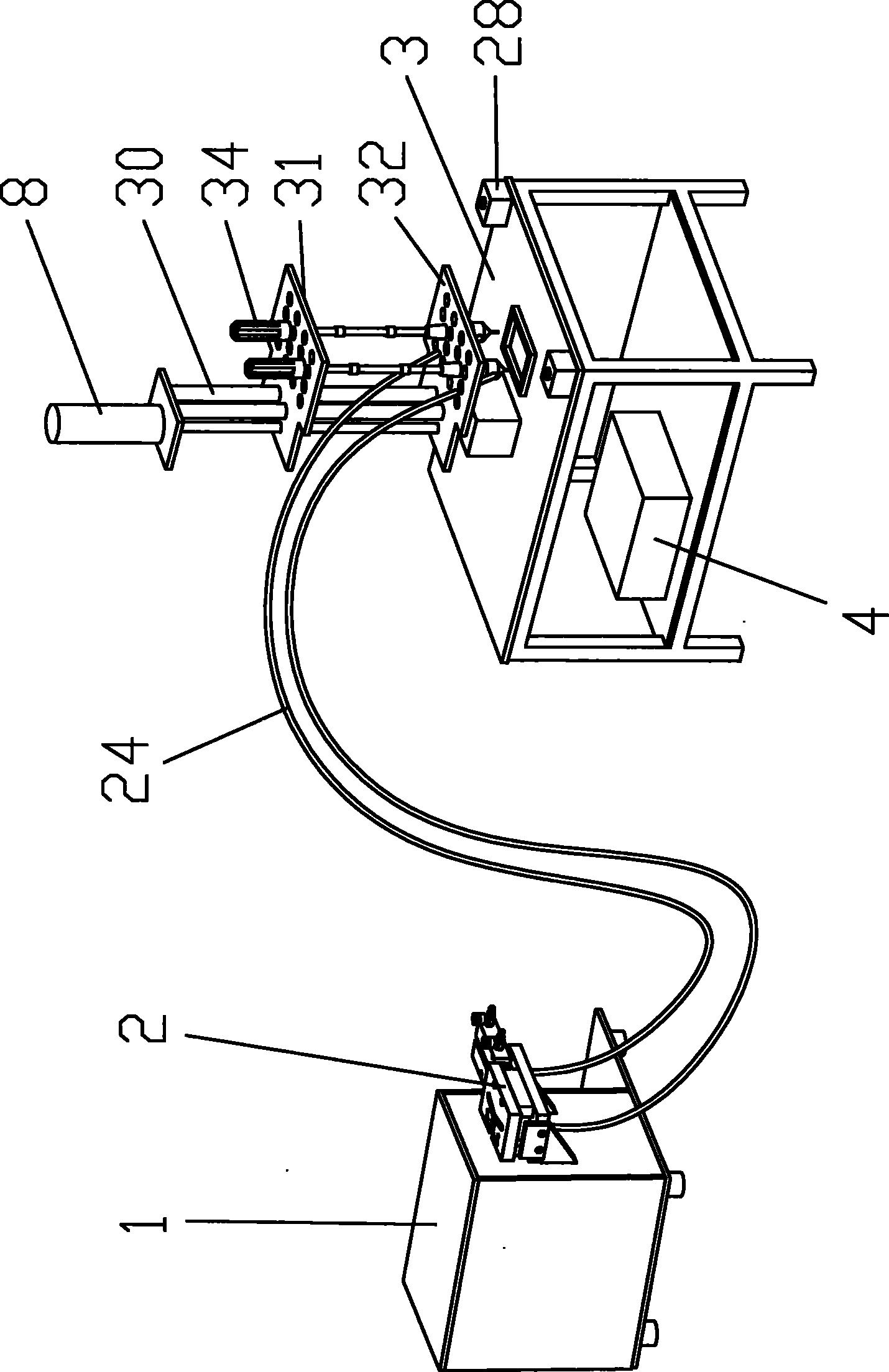

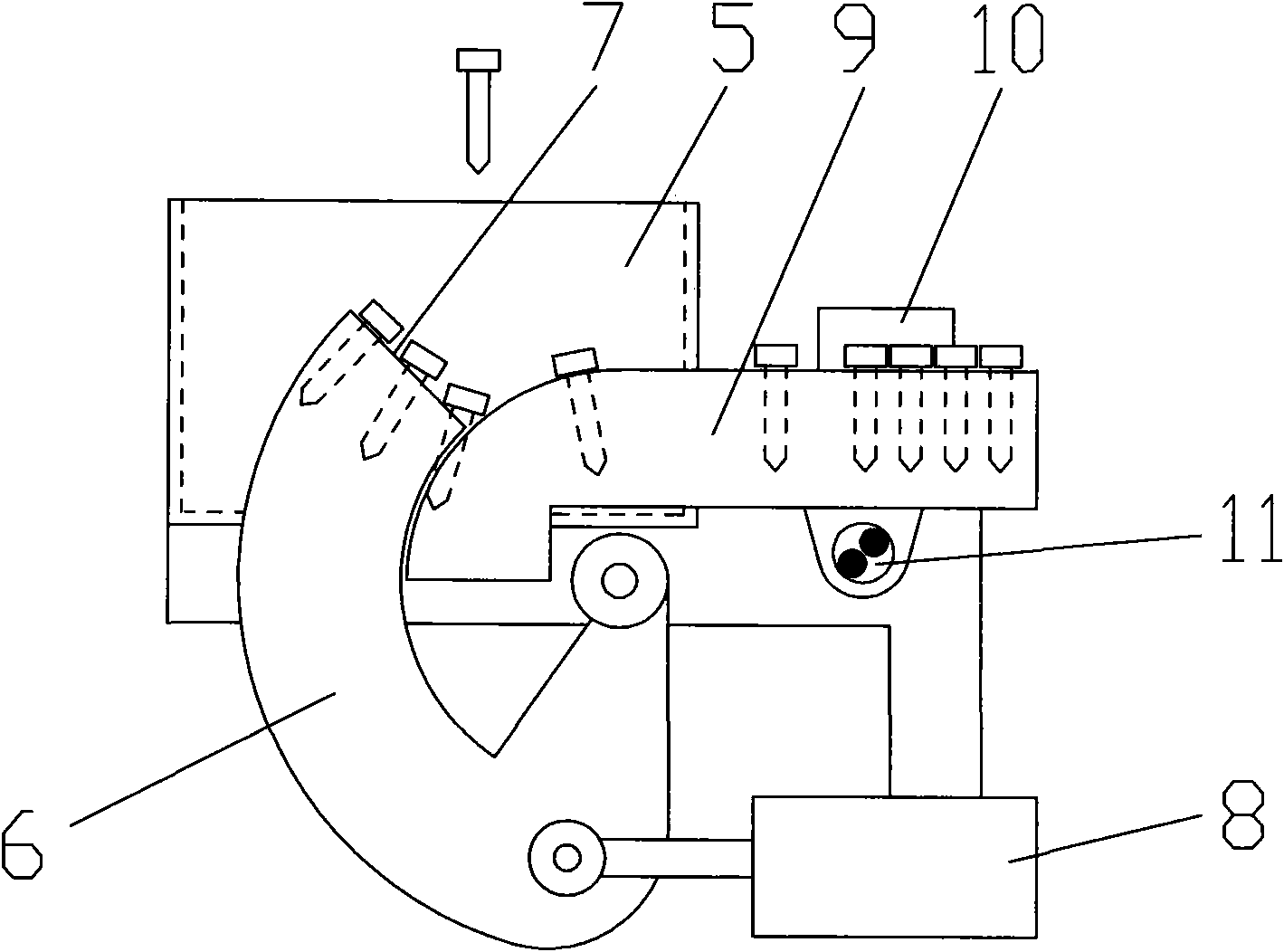

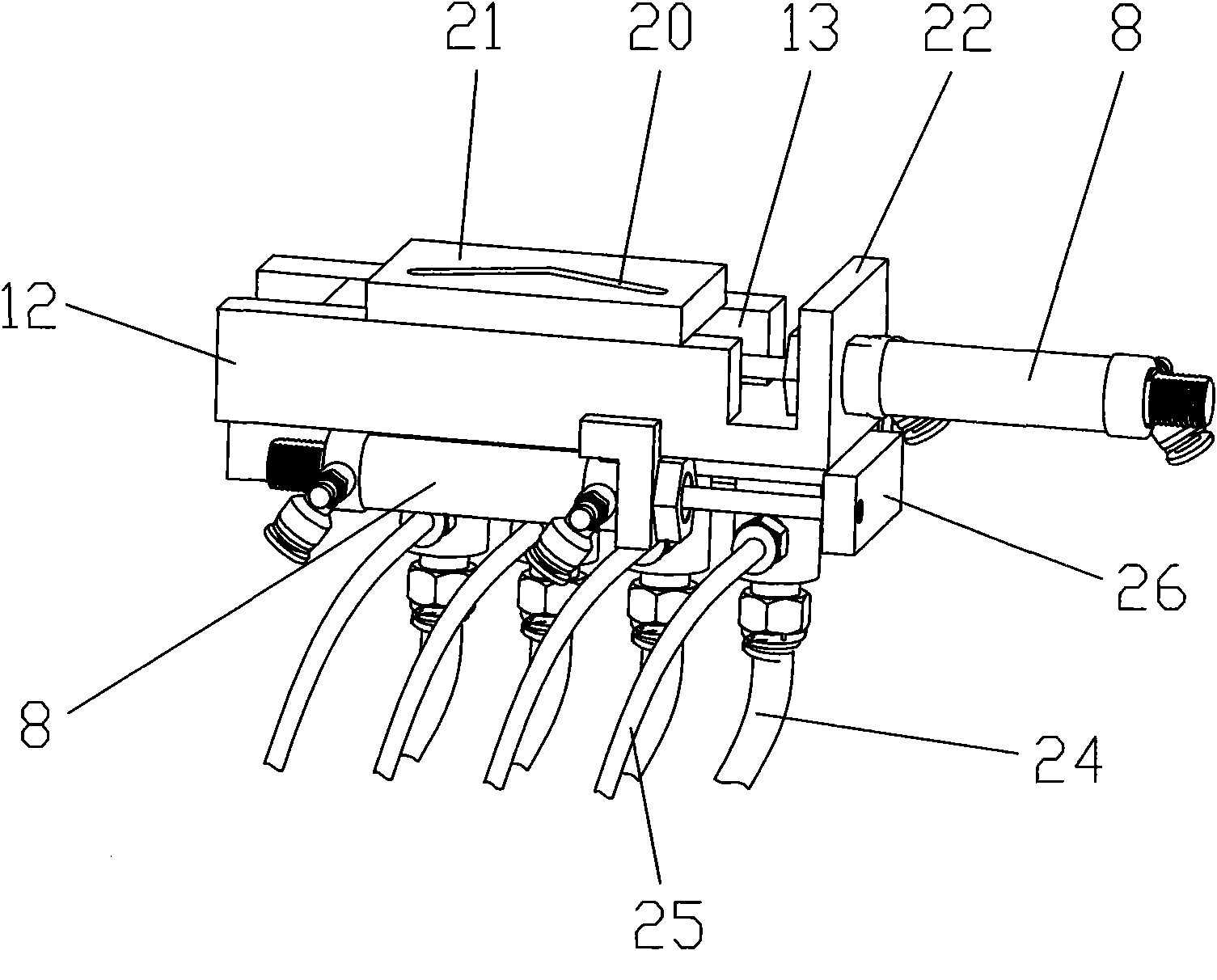

[0022] see Figure 1 to Figure 9 , a kind of automatic screw installation machine, screw delivery device 1, sub-screw device 2, screw installation mechanism 3 and gas-electric control system 4 are arranged, wherein screw delivery device 1 has hopper 5, is provided with groove at the bottom of hopper 5, A fan-shaped arrangement brush 6 is set in the slot, and a pick-up chute 7 is arranged in the middle of the upper side of the fan-shaped arrangement brush 6. A cylinder 8 is connected to the edge, and the cylinder 8 is connected with the gas-electric control system 4 through a pipeline, and a feeding guide rail 9 matching the inner arc edge is installed on the inner arc edge of the fan-shaped arrangement brush 6, and in the feeding guide rail 9 Equipped with a photosensitive sensor 10, the photosensitive sensor 10 is connected with the gas-electric control system 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com