Non-shaft high-precision static pressure numerical control rotary worktable

A rotary table, high-precision technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increased processing and assembly of turntable, complicated processing technology, complicated adjustment, etc., to reduce processing and assembly The effect of adjusting difficulty, good dynamic performance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

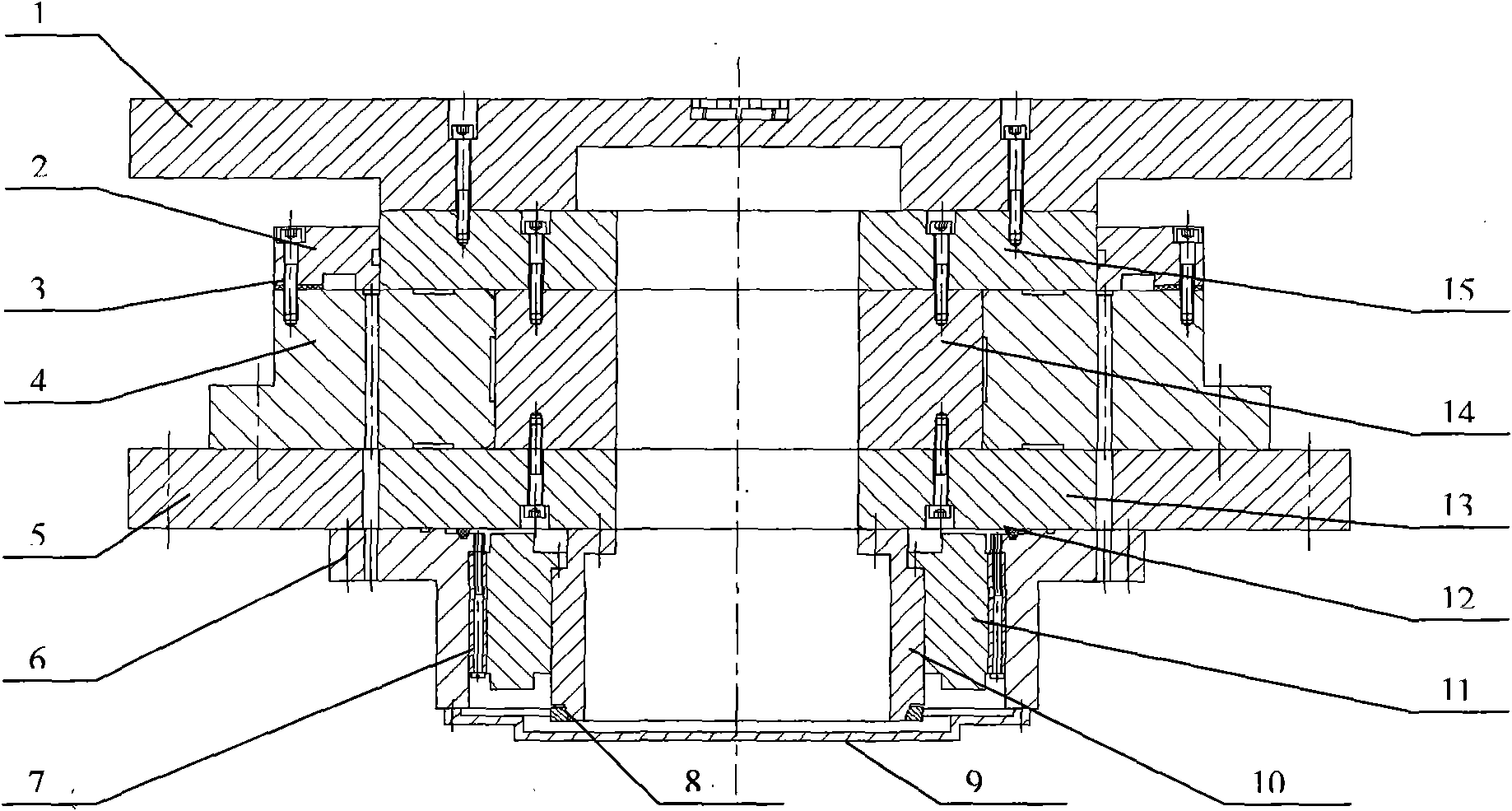

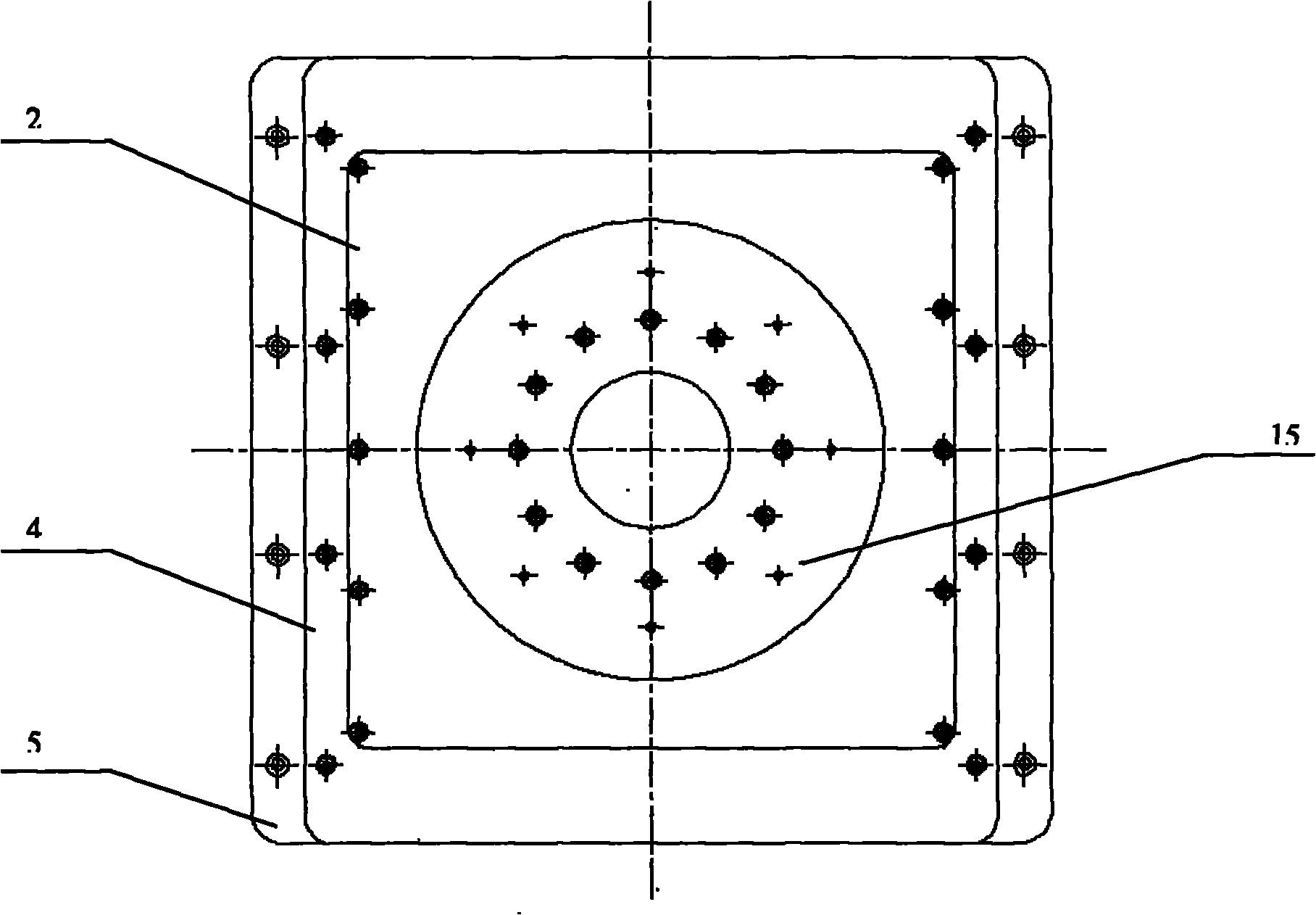

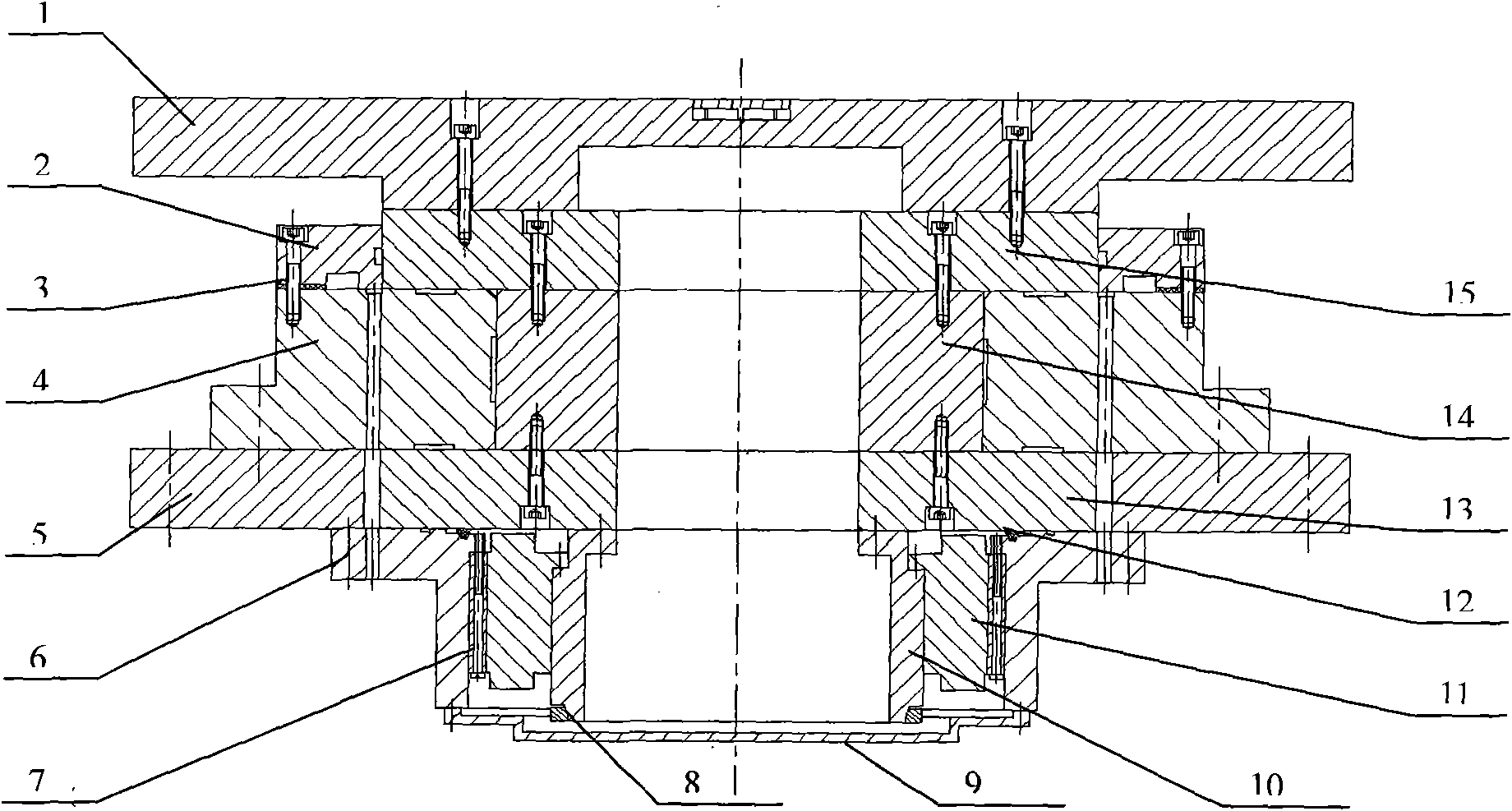

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0012] see figure 1 , the present invention includes a rotary table and a bearing stator 4 installed on the upper end of the fixed plate 5 of the rotary table, the bearing axial support 15 and the bearing axial downward support 13 are respectively installed on the upper and lower two ends of the bearing radial support 14 , and the bearing axial support 13 is located inside the rotary table fixed plate 5, the bearing axial support 15, the bearing axial support 13 and the bearing radial support 14 form the bearing rotor, which cooperates with the bearing stator 4 to form a liquid Hydrostatic bearing oil film, the oil separation ring cover plate 2 is installed on the upper end of the bearing stator 4, and the sealing gasket 3 is used to seal between the two; Air seal and sealing ring 12 double sealing method, the outer circle of the motor stator 7 is matched wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap