Main and auxiliary combined type air bag polishing tool

An airbag polishing and compound technology is applied in the field of polishing tools in the field of precision machining. Polishing track effect, realizing automation, the effect of good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

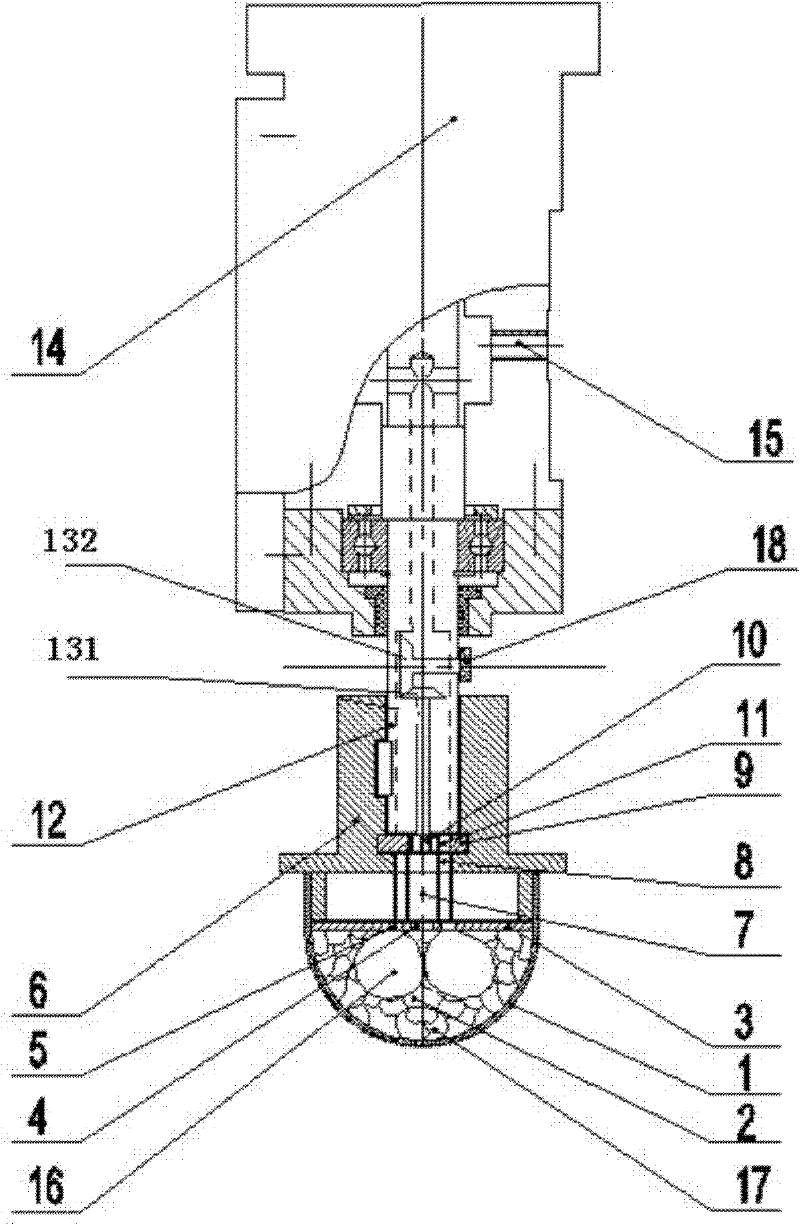

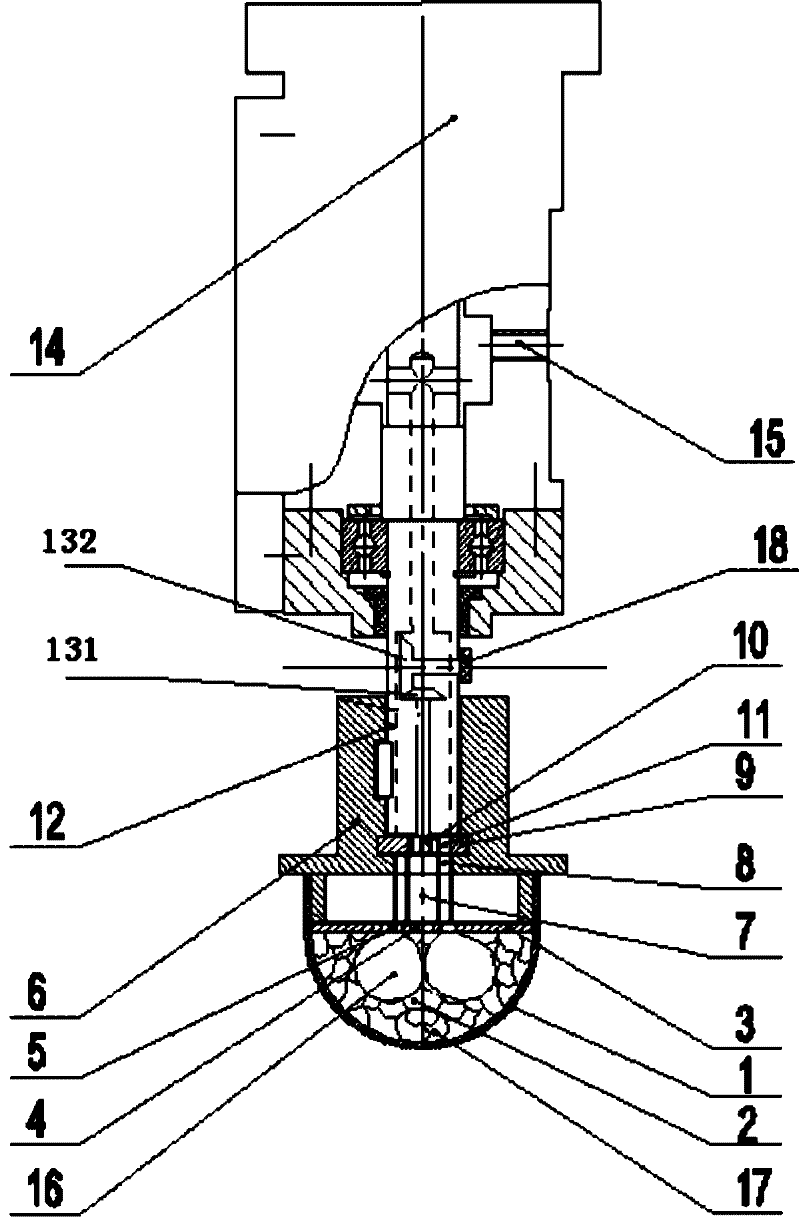

[0020] Below in conjunction with accompanying drawing, the utility model is further described.

[0021] The main and auxiliary composite airbag polishing tool includes an airbag, a gas transmission shaft 12 and an air pump, the airbag includes a cage 6 and an airbag cover 1, and the airbag cover 1 is sealed and installed on one end of the cage 6, the The cage 6 is a hollow structure; the gas transmission shaft 12 is a semi-hollow shaft, the hollow section of the gas transmission shaft 12 is connected to the other end of the cage 6, and the gas transmission shaft 12 The solid end is connected with a rotary drive mechanism 14; the gas transmission shaft 12 is sleeved in a gas conduction sleeve 15, and the gas conduction sleeve 15 is provided with a through hole, and the through hole is connected with the The air outlet of the air pump is connected, and the gas guide sleeve 15 is sealed with the gas transmission shaft 12;

[0022] The air bag is communicated with the gas transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com