A compressor piping system and refrigeration device

A piping system and refrigeration device technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as poor vibration damping effect, improve air column resonance, avoid mechanical structure resonance, and work smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

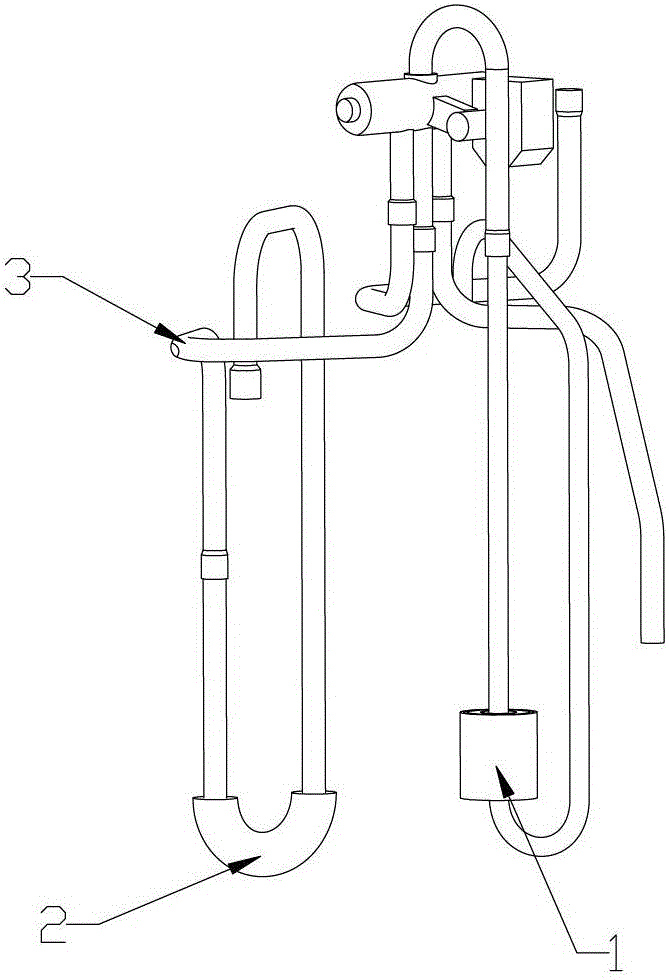

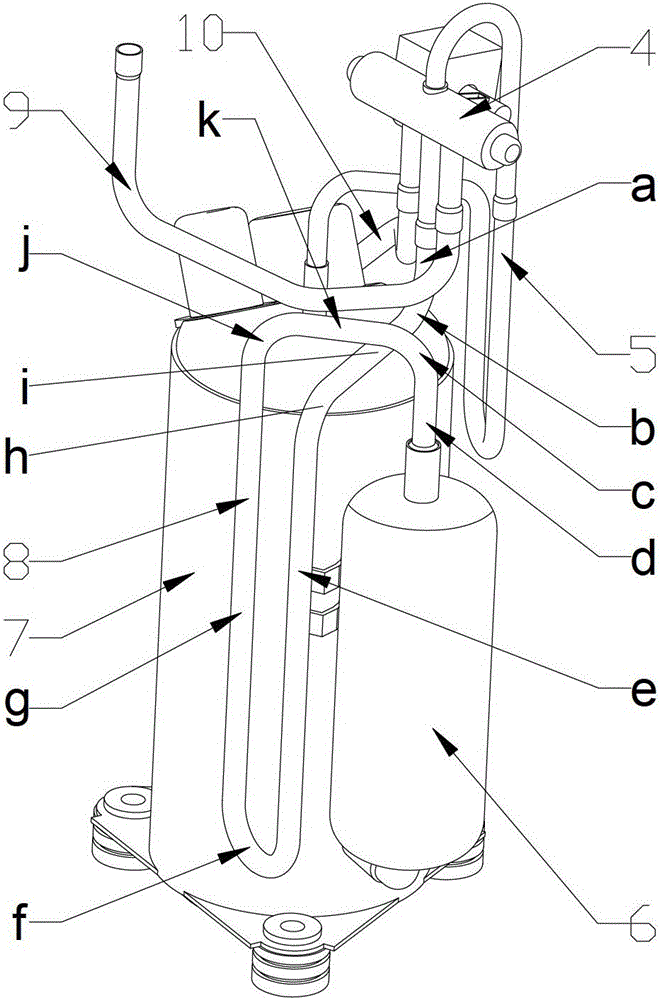

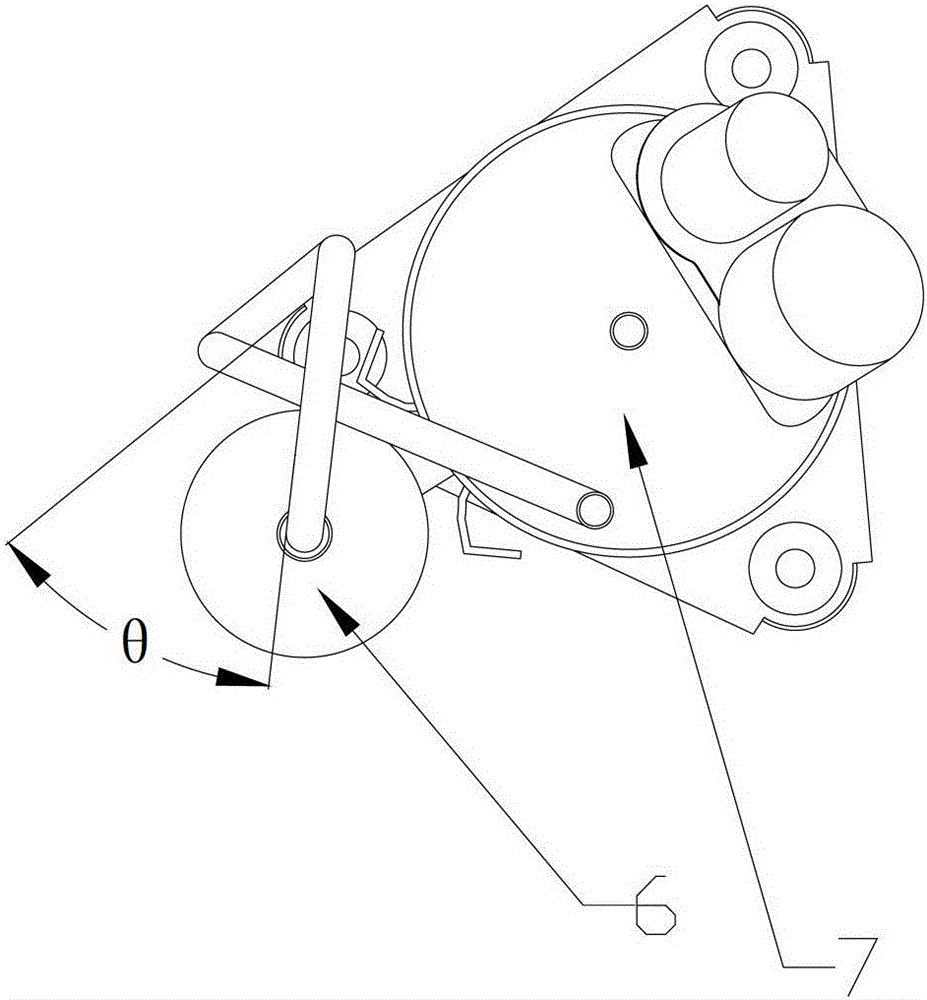

[0021] Such as figure 2 As shown, the compressor piping system provided by the embodiment of the present invention includes the electromagnetic reversing valve 4 and the air return pipe 8 connected to the electromagnetic reversing valve 4, where two pipe sections of the air return pipe 8 are in the shape of a three-dimensional intersection Take control. This design, on the one hand, balances the tangential vibration of the compressor due to the unbalanced rotor mass, and on the other hand, improves the refrigerant gas column resonance caused by the pulsating force, thereby avoiding the mechanical structure resonance of each operating frequency, so that each The pipeline can work smoothly during operation, and the vibration generated is small, thereby improving the stress distribution on the surface of the pipeline. At the same time, it avoids the addition of assembly weights, anti-vibration glue, etc. in the existing piping, and reduces the cost of materials, production and ...

Embodiment 2

[0031] Such as Figure 4 As shown, the difference between this embodiment and the first embodiment is that the air return pipe 8 and the exhaust pipe 5 are distributed on the same side of the compressor body 7 .

Embodiment 3

[0033] Such as Figure 5 As shown, the difference between the present embodiment and the first embodiment is that the "U" section of the air return pipe 8 is formed by tangentially connecting multiple sections of arc tubes and straight tubes, such as two sections of arc tubes m, p and Three sections of straight pipes e, n and g are connected tangentially.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com