Control method of surface stress and strain field of casing parts based on constant cutting force

A surface stress and control method technology, applied in computer control, program control, digital control, etc., can solve problems such as the control method of stress and strain field on the surface of complex casing parts of aero-engines that have not yet been disclosed, and achieve huge economic and social benefits , strong versatility and practicability, and the effect of good practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

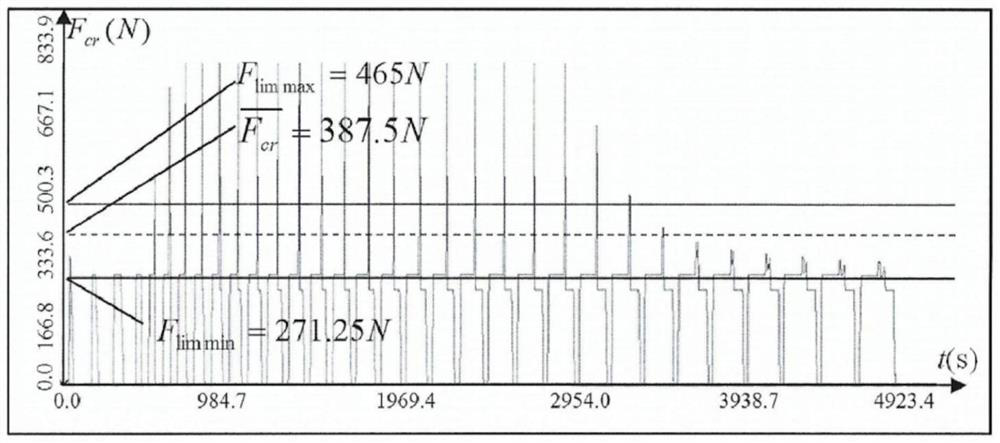

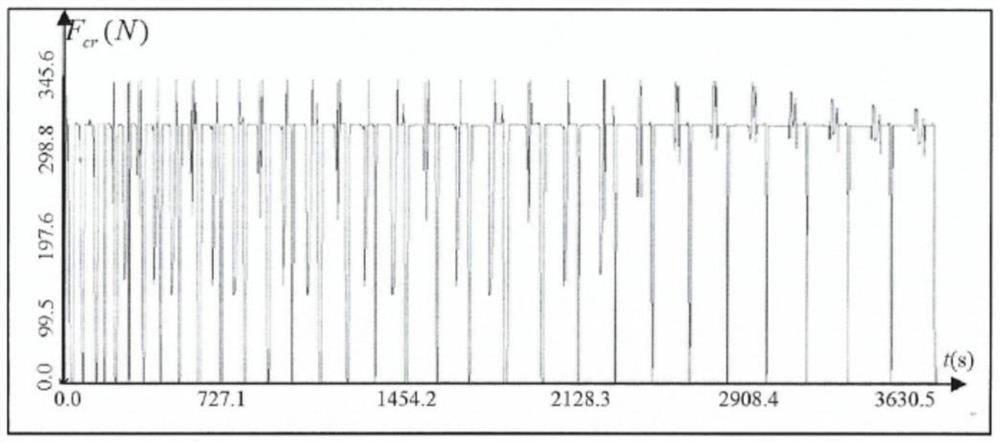

[0047] The present invention proposes a method for controlling the stress-strain field on the surface of casing parts based on constant cutting force, comprising the following steps:

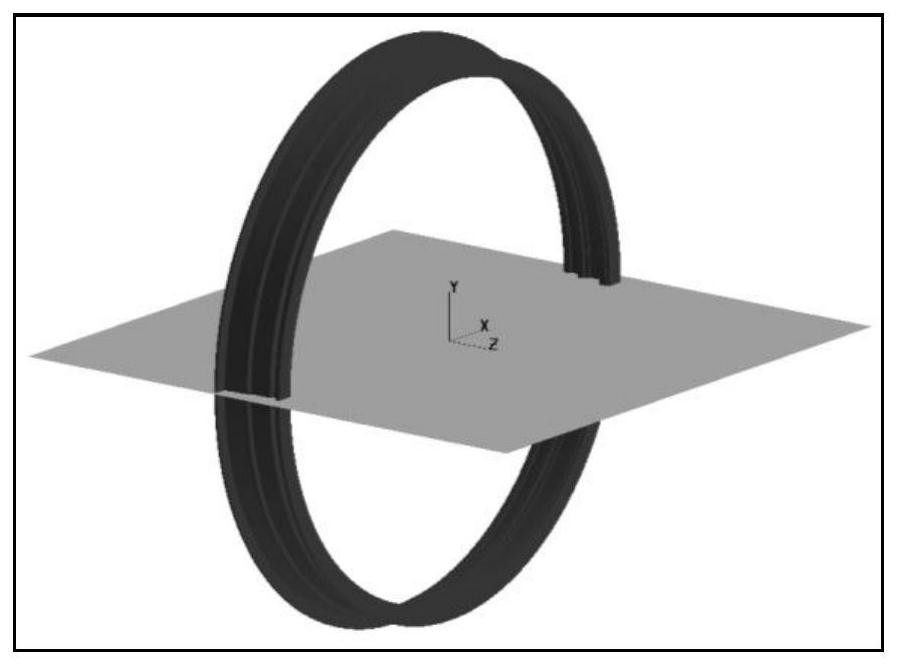

[0048] Step 1, importing the part model, i.e. the CAD model of the part target shape, into the computer;

[0049] Step 2, importing the original CNC program into the computer;

[0050] The original numerical control program includes cutting parameters, tool path and tool swing angle, which are used to control the machine tool to perform corresponding processing actions; the original numerical control prog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com