Device and process for growing TiAlN film on surface of aluminum alloy in situ

An aluminum alloy surface and in-situ growth technology, which is applied in metal material coating process, ion implantation plating, coating, etc., to achieve high bonding strength, improved surface stress distribution, and high microhardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

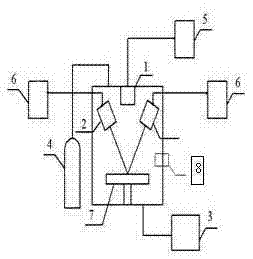

[0019] Further explain below in conjunction with accompanying drawing:

[0020] Such as figure 1 As shown, a device for in-situ growth of TiAlN film on the surface of aluminum alloy, the device can reach 1×10 -3 ~5×10 -4 On the vacuum chamber which can be filled with gas medium, ion implantation source 1, magnetron sputtering target 2, vacuum system 3, gas supply system 4, ion implantation control power supply 5, magnetron sputtering control power supply 6, rotating The workpiece support 7 and some auxiliary observation windows and thermometers, the magnetron sputtering target 2 are connected to the magnetron sputtering control power supply 6, the ion implantation source 1 is connected to the ion implantation control power supply 5, the vacuum system 3 and the gas supply system 4 are respectively Connected with the vacuum chamber of the device, the ion implantation source 1, the magnetron sputtering target 2, and the rotating workpiece support 7 are all fixed in the vacuum c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com