Disassembling tool

A technology for disassembling tools and tools, which is applied in the direction of manufacturing tools and hand-held tools, etc., can solve the problems that different oil filters cannot be applied, and achieve the effect of simple structure and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

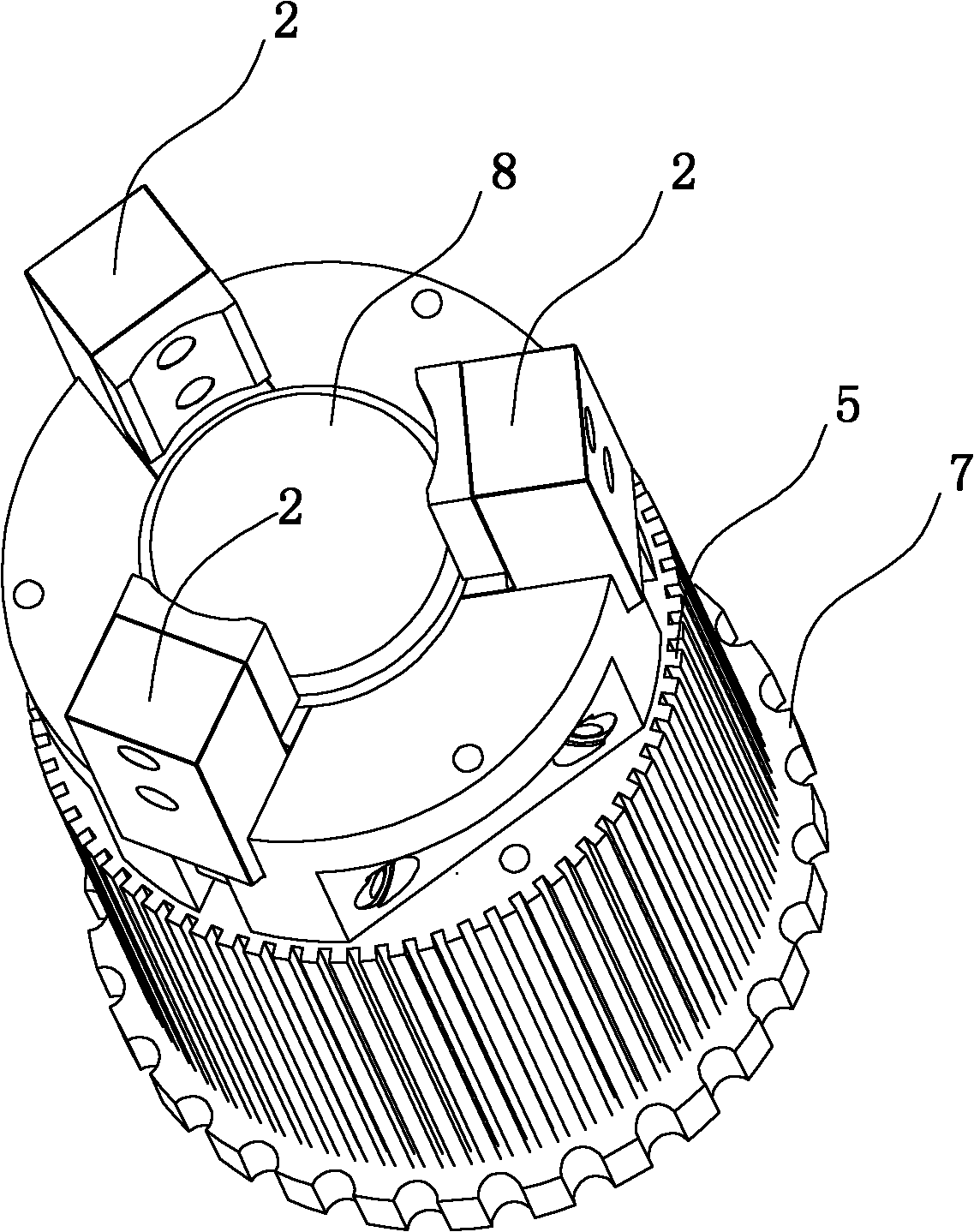

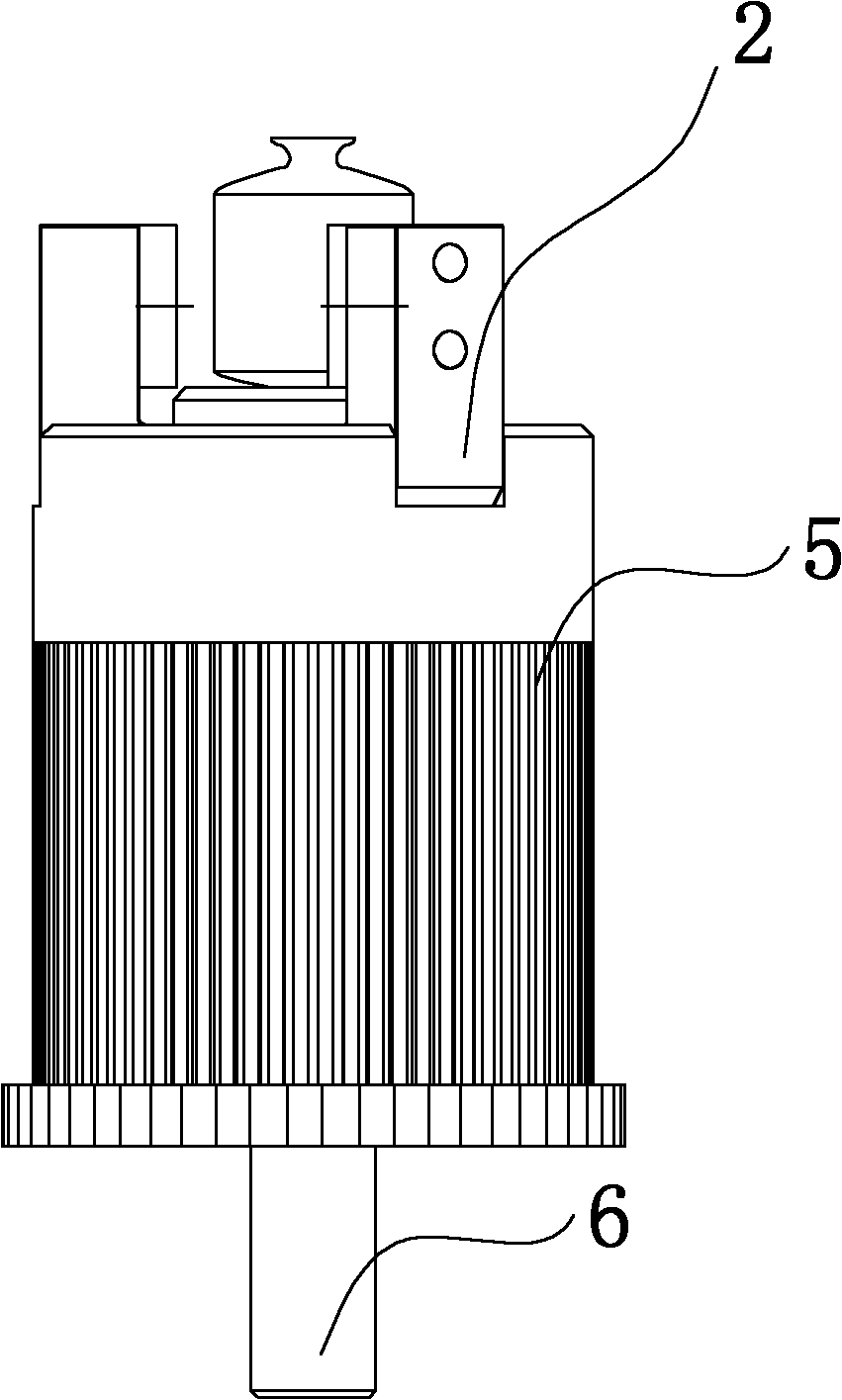

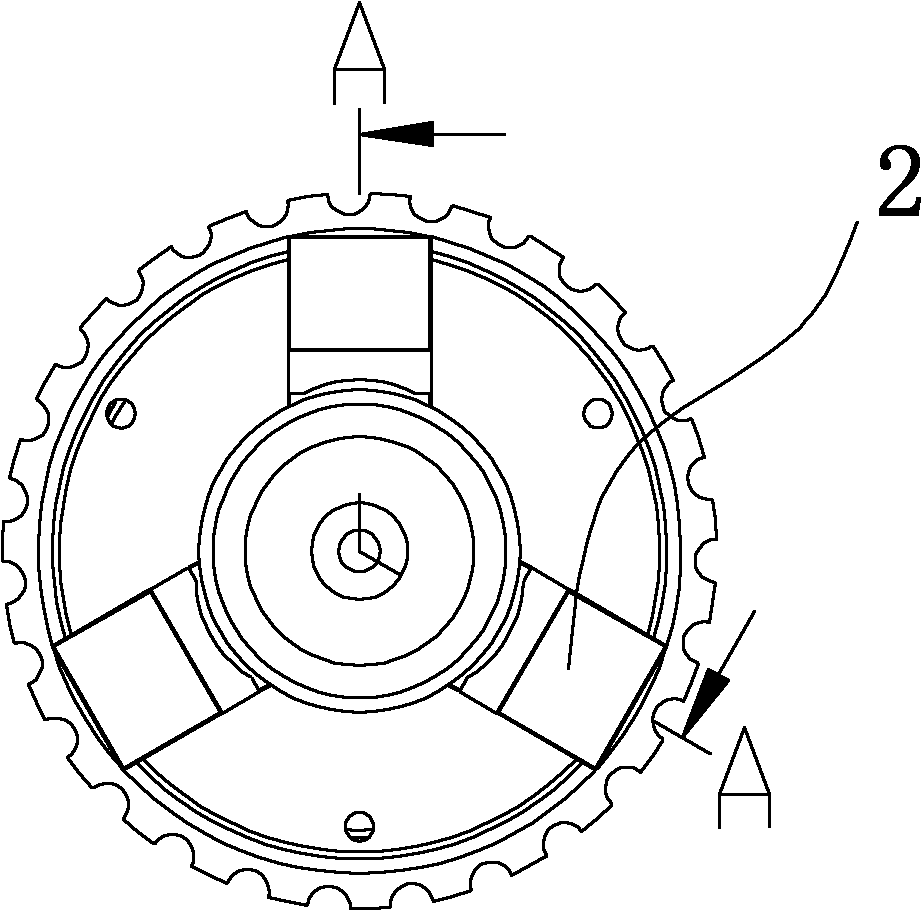

[0036] With reference to accompanying drawing, further illustrate the present invention:

[0037] The assembly and disassembly tool includes a clamp, a cylinder body 5 and a stepped shaft 6 placed in the cylinder body, the shoulder of the stepped shaft 6 is connected with the inner surface of the cylinder body 5 through threads, and the stepped shaft 6 The bottom is provided with an insertion hole 63 that allows the flying wrench to be inserted to drive the rotation of the stepped shaft 6; the clamp includes a plurality of jaws 2, and the jaws 2 pass through a V-shaped rocker arm 3 and the stepped shaft respectively. 6 connection; the corner of the rocker arm 3 is hinged with the cylinder 5 through the pin 4, the upper end of the rocker arm 3 is hinged with the corresponding jaw 2, and the lower end of the rocker arm 3 is hinged by The first ball joint is connected to the stepped shaft 6, the lower end 34 of the rocker arm is spherical, and the stepped shaft 6 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com