Device for handling a container with directly actuated transport wheel

A technology for handling containers and driving wheels, applied in liquid handling, conveyors, conveyor objects, etc., can solve the problems of unable to achieve synchronous braking, hindering synchronous braking, etc., to save maintenance intervals, reduce noise, and reduce overall efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The technical solutions of the present invention will be further described below in conjunction with the examples, but the present invention is not limited thereto.

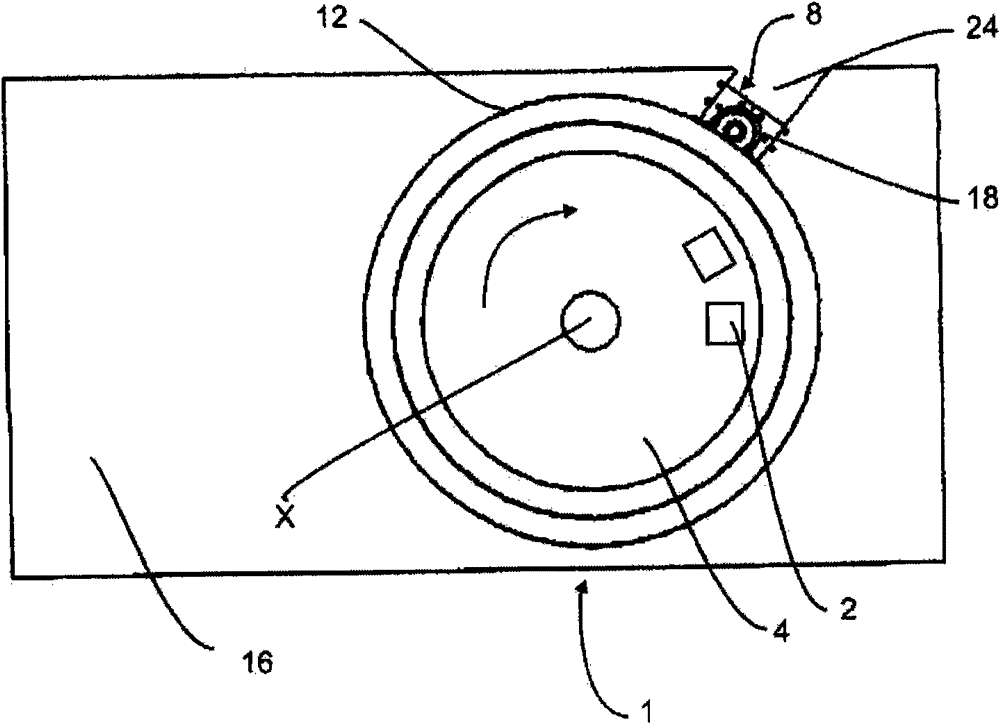

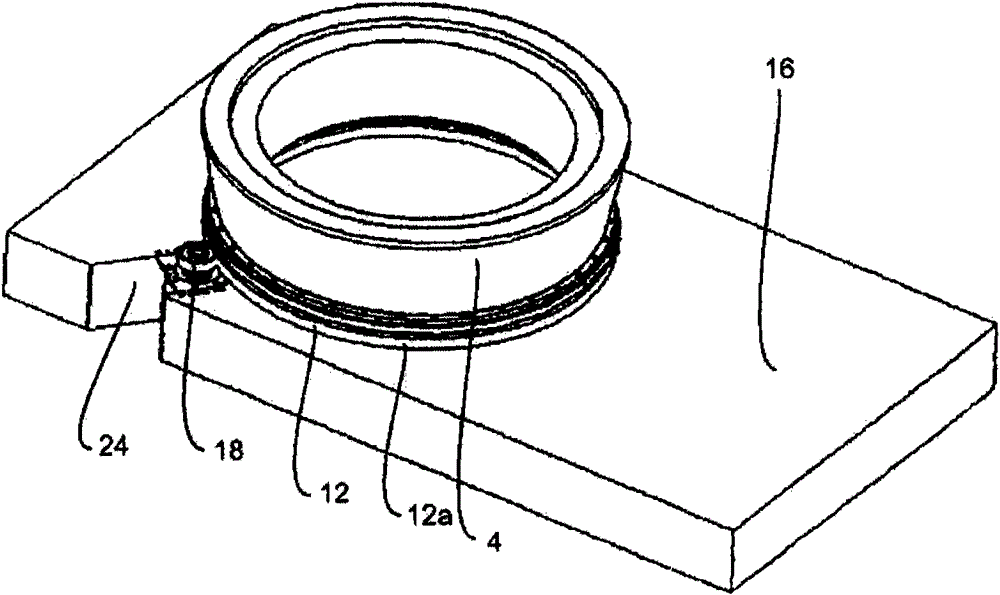

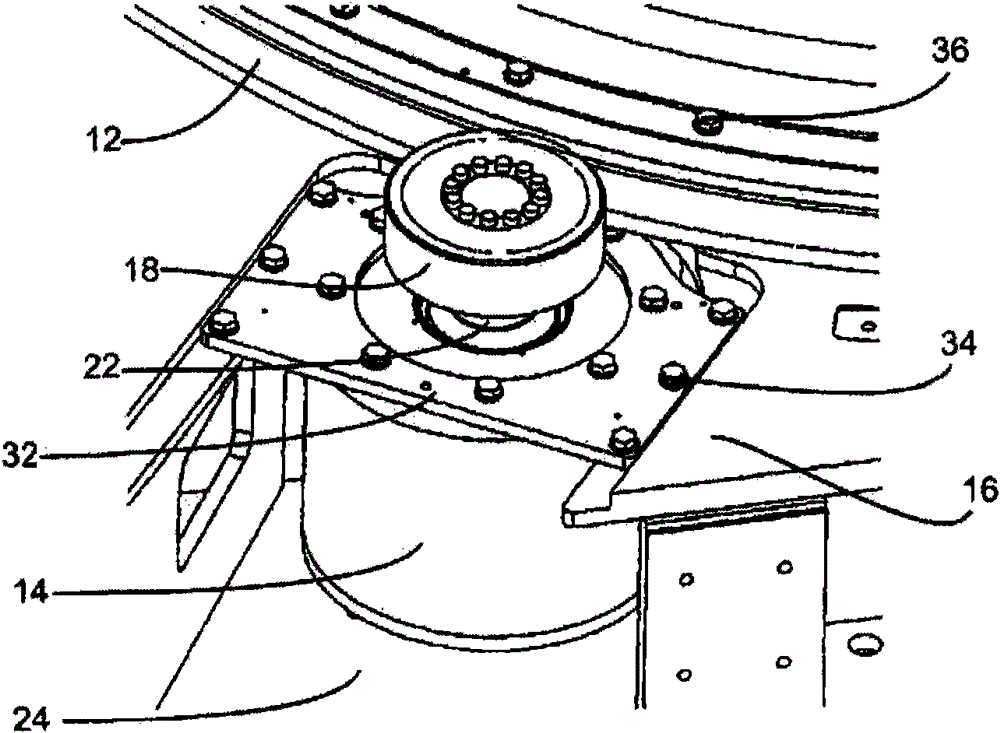

[0065] figure 1 A top view of a device 1 according to the invention for processing containers (not shown), more precisely a schematic view of a blow molding machine for processing plastic preforms into plastic containers, is shown. Furthermore, the device 1 has a mount 4 arranged rotatably about an axis of rotation X. FIG. Furthermore, the support 4 is placed opposite a base 16 . On the outer periphery of the support there is a drive wheel 12 which is driven by a drive device which is designated as a whole by the reference numeral 8 .

[0066] Furthermore, the drive device has a driven wheel 18 for driving the bearing 4 in rotation. Reference numeral 2 designates a container treatment unit, shown only schematically. A plurality of said processing units 2 are arranged on the support 4 . The drive wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com