Aluminum thermal fin material

A heat sink and aluminum plate technology, applied in the field of aluminum heat sink materials, can solve the problems of reduced hydrophilicity, ambiguity, and difficulty in maintaining the surface hydrophilicity of heat sink materials for a long time, so as to achieve effective heat exchange and reduce occlusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

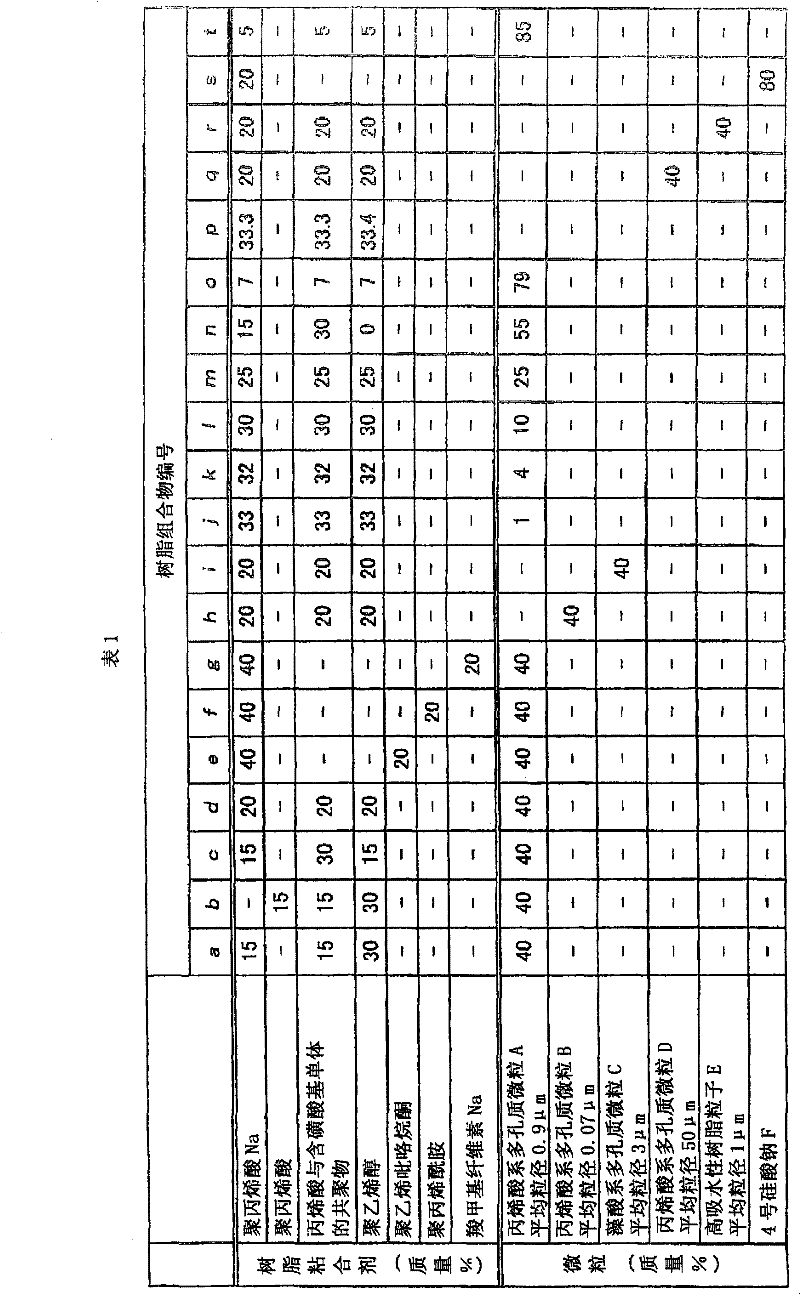

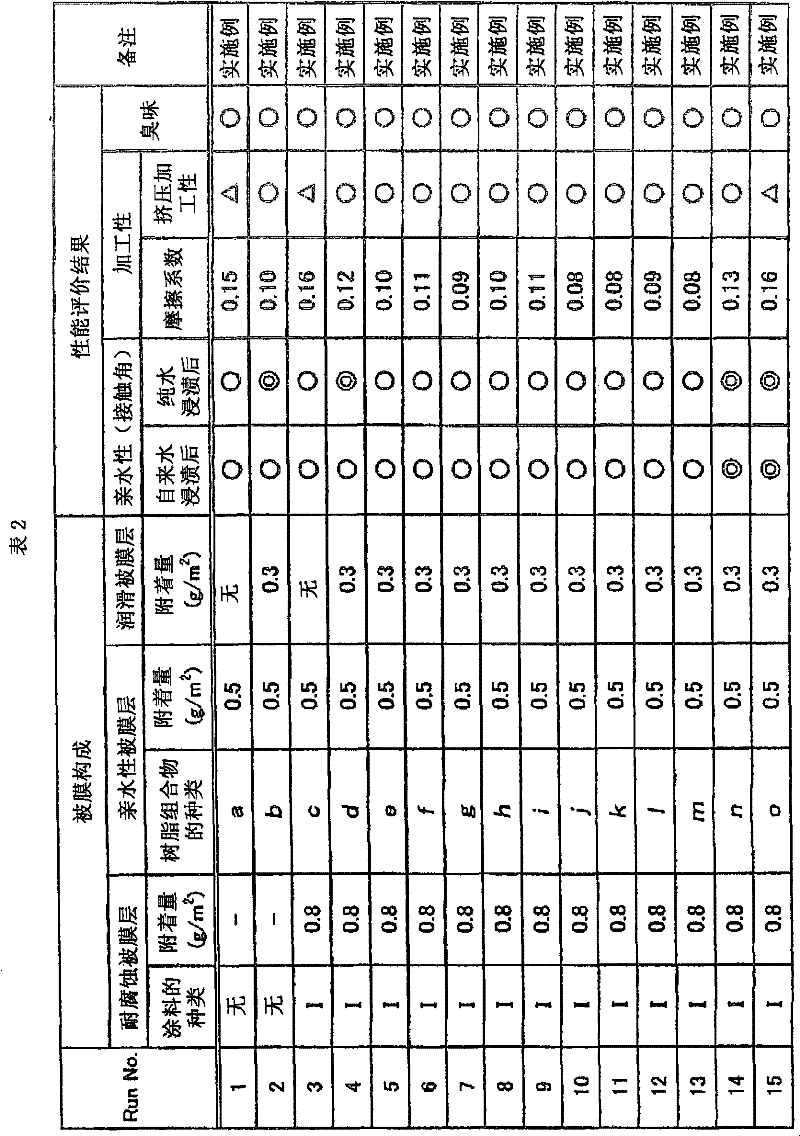

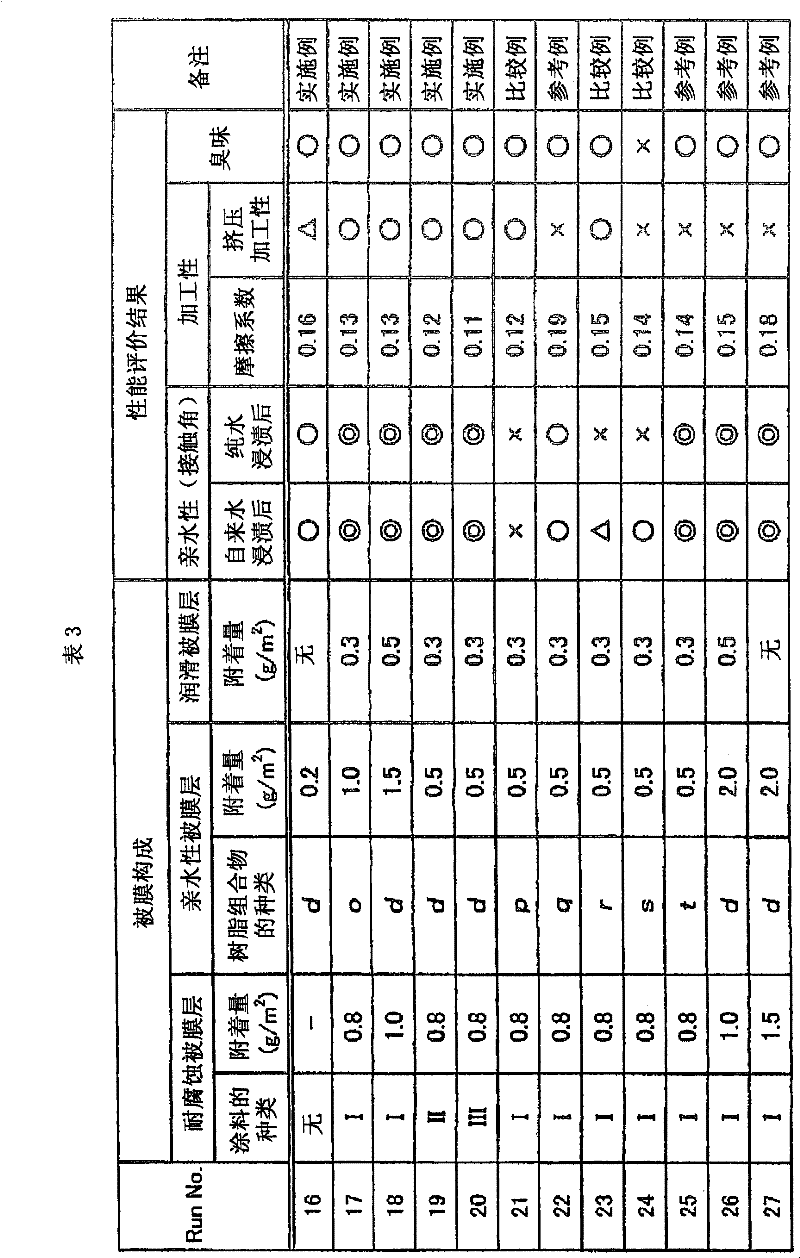

Method used

Image

Examples

Embodiment Construction

[0020] The aluminum heat sink material of the present invention has a hydrophilic coating layer obtained from a resin composition containing a specific resin binder and porous fine particles. It is considered that this resin binder imparts excellent hydrophilicity to the coating layer, and at the same time, part of the dew condensation water adhering to the surface of the heat sink material penetrates into the coating layer and is absorbed into the open pores of the porous particles. The contact angle of the layer with respect to water becomes smaller, and it becomes possible to suppress blocking between the fin pieces. In addition, the moisture absorption performance of the porous fine particles is exerted for a long period of time, so the hydrophilicity of the heat sink material of the present invention is also maintained for a long period of time.

[0021] The heat sink material of the present invention is made of an aluminum plate or an aluminum alloy plate. From the viewpoin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com