Wear-resistant anti-fog easy-to-clean resin spectacle lens and manufacturing method thereof

A technology of resin lenses and spectacle lenses, applied in the directions of glasses/goggles, optics, instruments, etc., can solve the problems of hydrophilic attenuation, poor anti-fogging effect, and high reactivity of hydrophilic groups, and achieve lasting and effective fogging, The effect of strong contamination resistance and enhanced wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

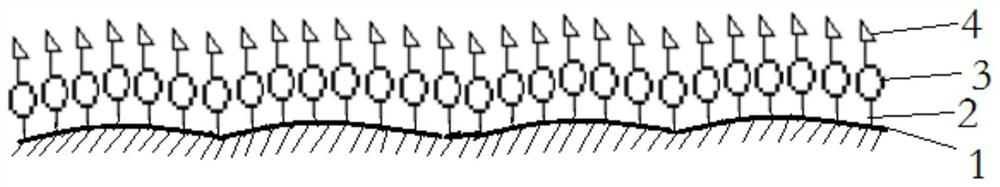

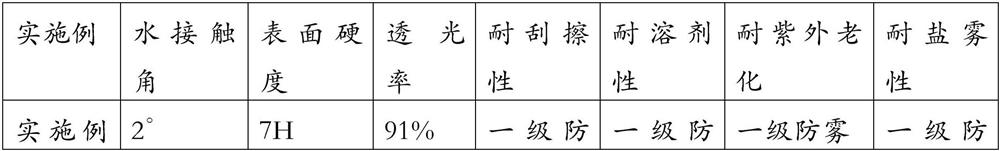

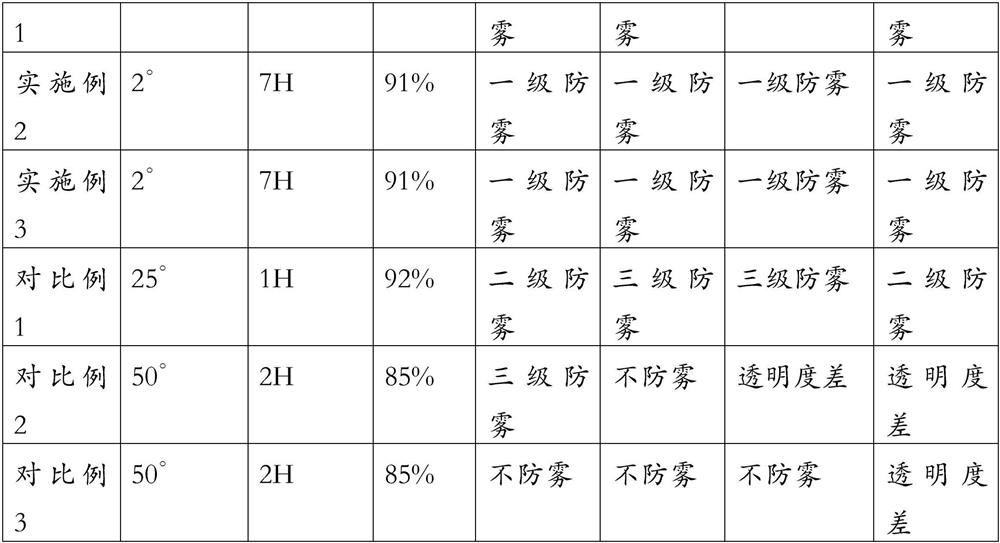

[0045] Embodiment 1: A wear-resistant, anti-fog and easy-to-clean resin spectacle lens. The two surfaces of the resin lens include a five-layer structure from the inside to the outside. Three-layer composite anti-reflection coating, the fourth nano-silicon dioxide coating, and the fifth nano-superhydrophilic anti-fog coating. . First, ultrasonically clean the resin lens, then use clear water and pure water to clean the resin lens for the second time, and then immerse the resin lens in the siliconized hardening coating for 15 seconds. The siliconized hardening coating uses methyltriethoxysilane and ethyl orthosilicate as main raw materials, and uses isopropanol and deionized water as solvents, and the molar ratio of the four is 5:4:22:3. The pH value of the mixed solution is adjusted between 1.5-2 with a diluent solution of 5% hydrochloric acid in isopropanol. Stir at a constant temperature of 45°C until the mixture becomes clear, and then stand still for 2 hours. Then add l...

Embodiment 2

[0048] A wear-resistant, anti-fog, and easy-to-clean resin spectacle lens. The two surfaces of the resin lens include a five-layer structure from the inside to the outside, the first layer of siliconized hardened film layer, the second layer of nano-alumina The transparent film layer, the fourth nano-silica film layer, and the fifth nano-superhydrophilic anti-fog film layer. The siliconized hard coat layer includes 13 parts of methyl triethoxysilane, 7 parts of ethyl orthosilicate and 13 parts of dibutyltin dilaurate, the methyl triethoxysilane, ethyl orthosilicate and Dibutyltin dilaurate was mixed with each other to prepare the siliconized hardening layer coating, the mixing temperature was 135°C, and the mixing was done for 4 hours. Firstly, ultrasonically clean the resin lens, then use clear water and pure water to clean the resin lens for the second time, and then immerse the resin lens in the siliconized hardening coating for 23 seconds. The siliconized hardening coating...

Embodiment 3

[0051] A wear-resistant, anti-fog, and easy-to-clean resin spectacle lens. The two surfaces of the resin lens include a five-layer structure from the inside to the outside, the first layer of siliconized hardened film layer, the second layer of nano-alumina The transparent film layer, the fourth nano-silica film layer, and the fifth nano-superhydrophilic anti-fog film layer. The siliconized hard coat layer includes 15 parts of methyl triethoxysilane, 8 parts of ethyl orthosilicate and 15 parts of dibutyltin dilaurate, the methyl triethoxysilane, ethyl orthosilicate and Dibutyltin dilaurate was mixed with each other to prepare the siliconized hardening layer coating, the mixing temperature was 150°C, and the mixing was done for 5 hours. Firstly, ultrasonically clean the resin lenses, then use clear water and pure water to clean the resin lenses for the second time, and then immerse the resin lenses in the siliconized hardening coating for 30 seconds. Silane and tetraethyl orth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com