Resin-coated metal plate and fin material for heat exchanger composed of the same

A metal plate and resin technology, applied in the field of resin-coated metal plates, can solve the problems that cannot be said to meet the hydrophilic characteristics, no contact angle of metal plates, etc., to achieve effective heat exchange and reduce occlusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

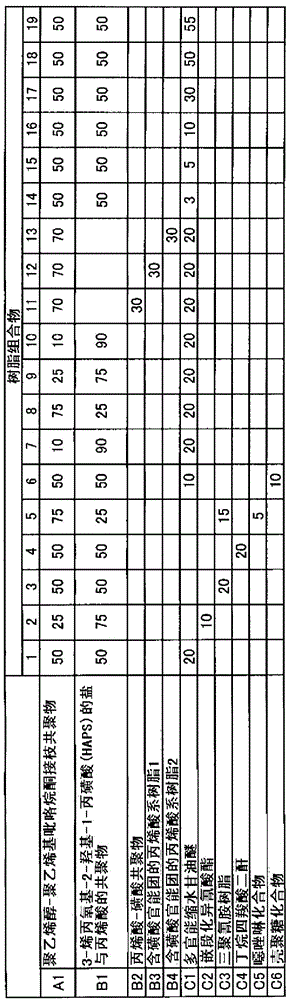

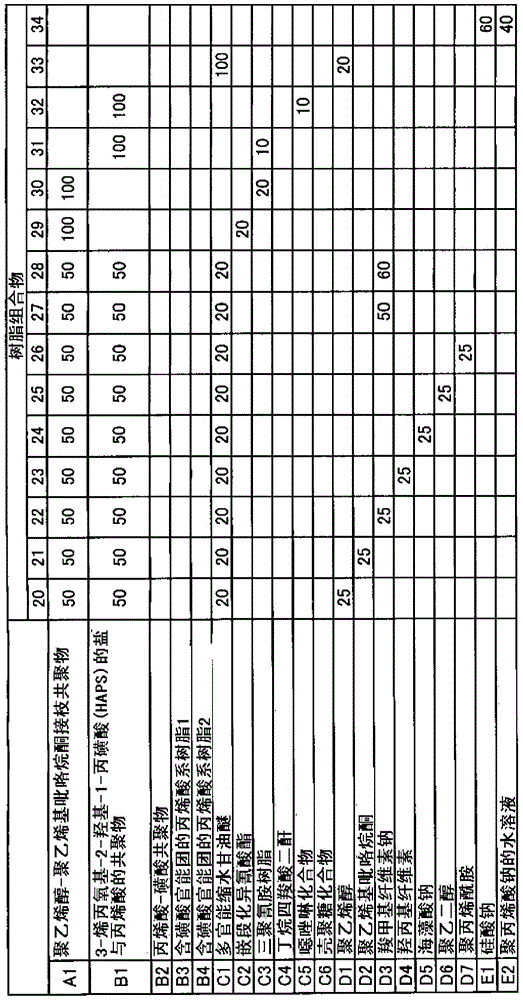

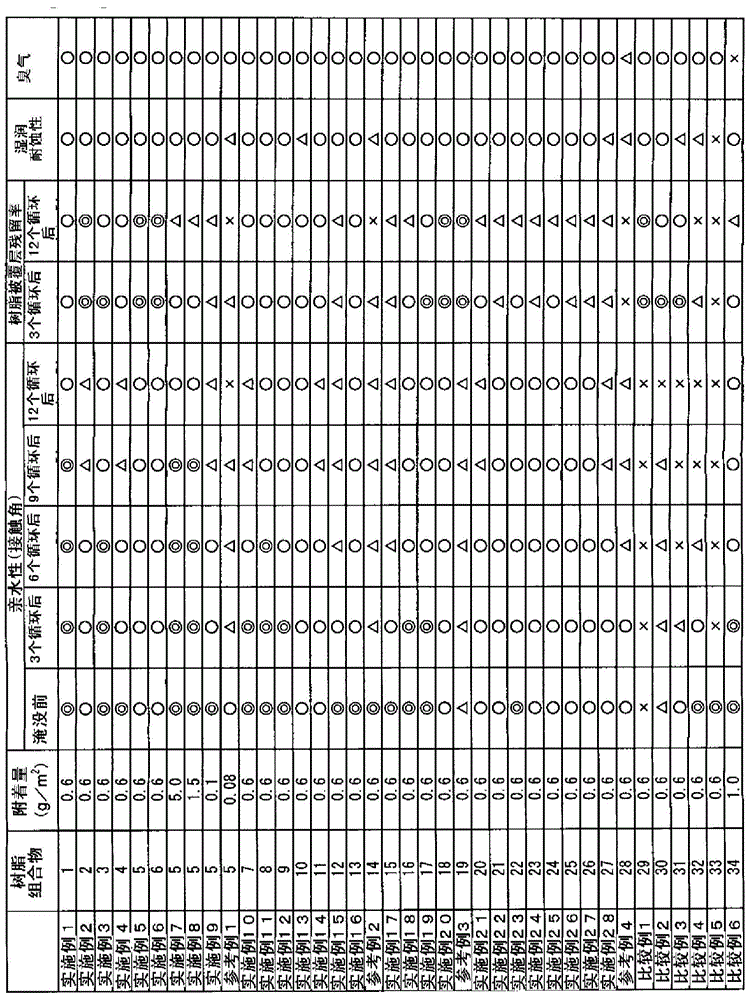

[0060] The present invention will be further described in detail through the following examples, but the following examples do not limit the present invention, and all changes and implementations within the scope of not departing from the gist of the present invention are included in the present invention.

[0061] Hereinafter, "%" means "mass %", and "part" means "mass part".

[0062] [Manufacturing method of test material]

[0063] An aluminum plate (sheet thickness: 0.10 mm) made of pure aluminum-based A1200 (JIS H4000) was produced by a conventionally known production method. This aluminum plate was degreased with an alkaline agent (“Surfcleaner (registered trademark) 360” manufactured by Nippon Paint Co., Ltd.), and subjected to phosphoric acid chromate treatment. The adhesion amount of the chemical conversion treatment film is set to 30mg / m2 in terms of Cr conversion 2 .

[0064] [Manufacturing method of aluminum fin material]

[0065] A resin composition was prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com