Roller type mechanical brake

A mechanical brake and roller type technology, applied in the direction of brake type, brake parts, mechanical equipment, etc., can solve the problems of inconvenience, short service life of brake components, etc., and achieve good impact reduction, good isolation of torsional vibration, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

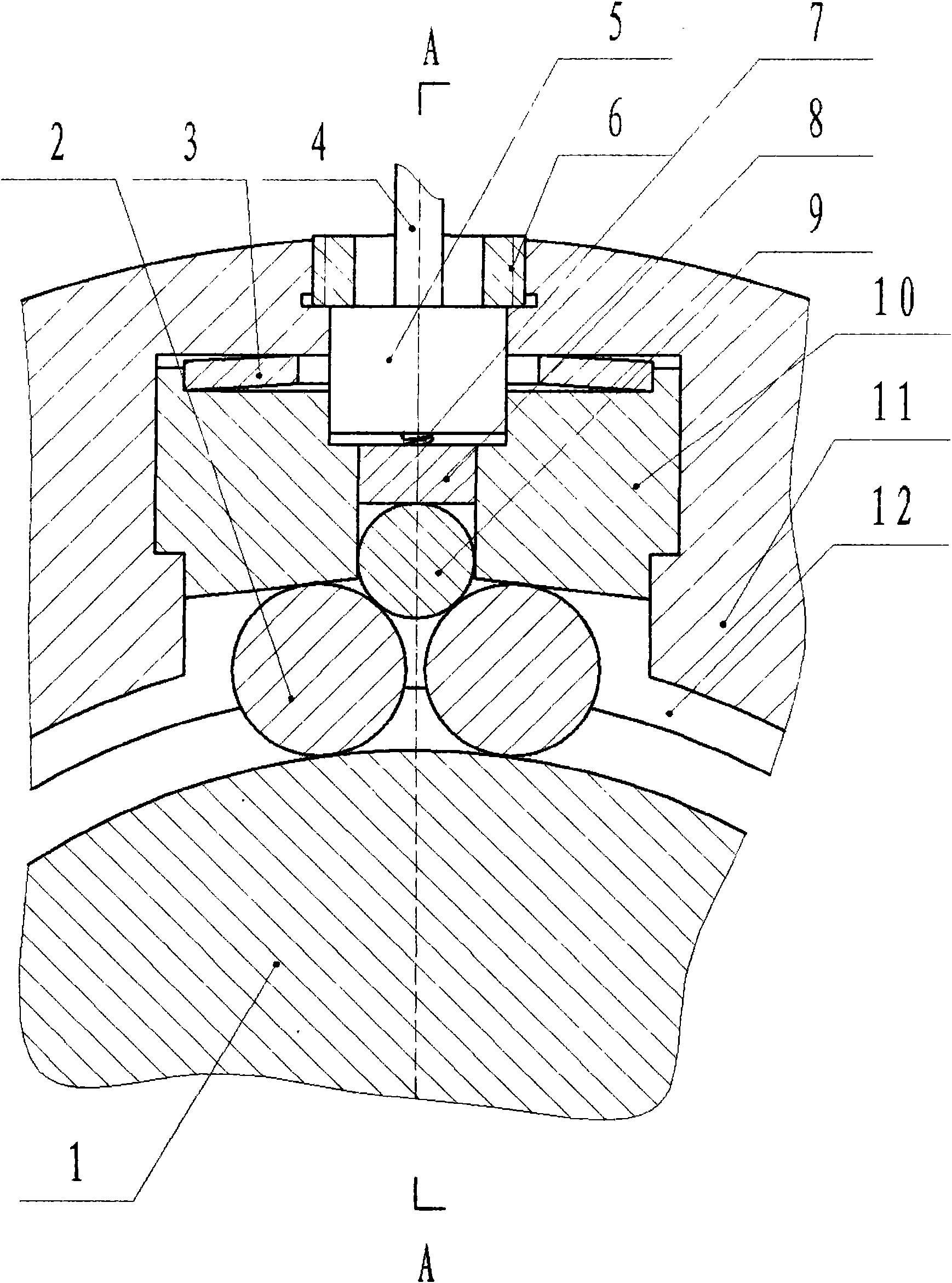

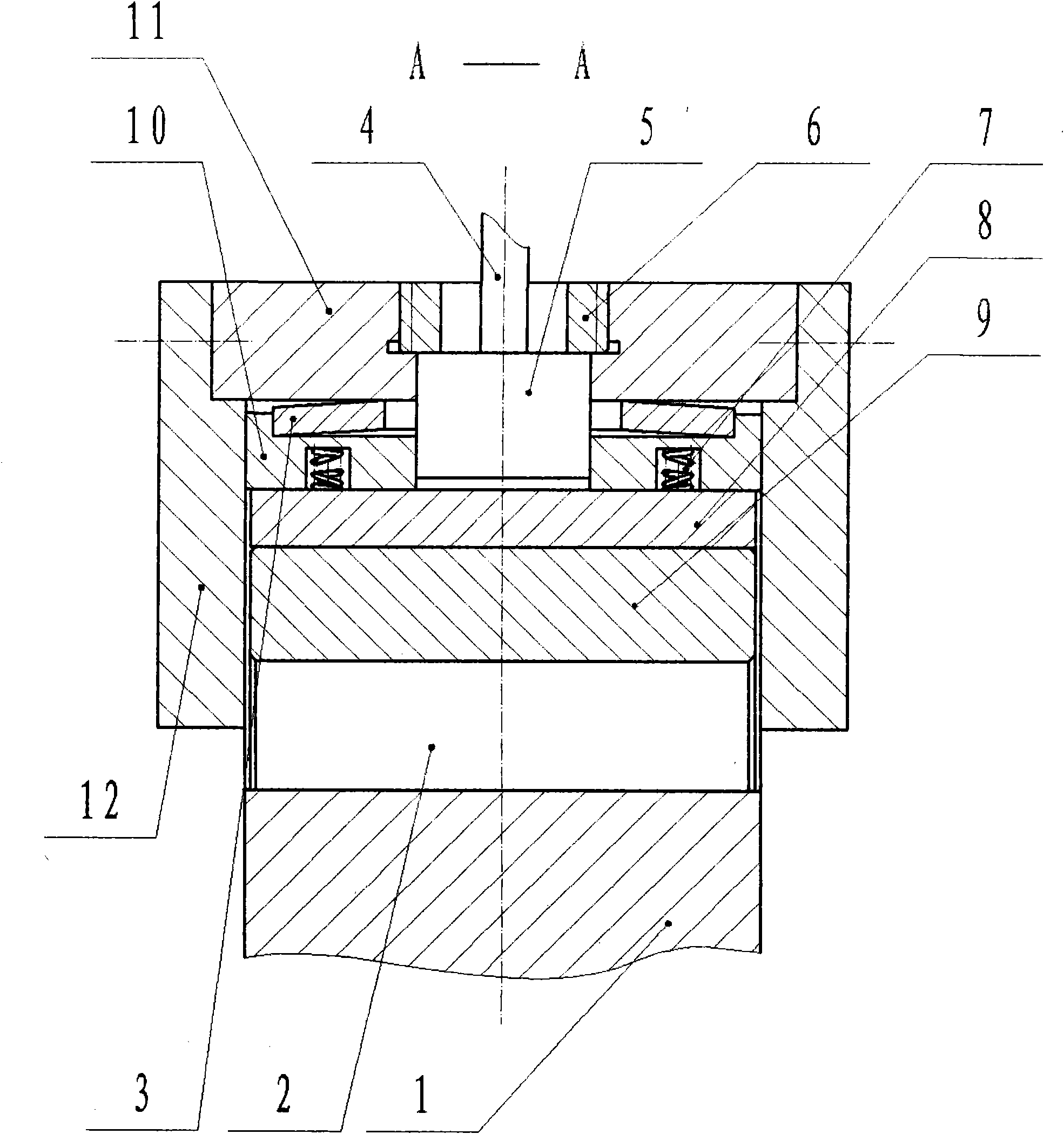

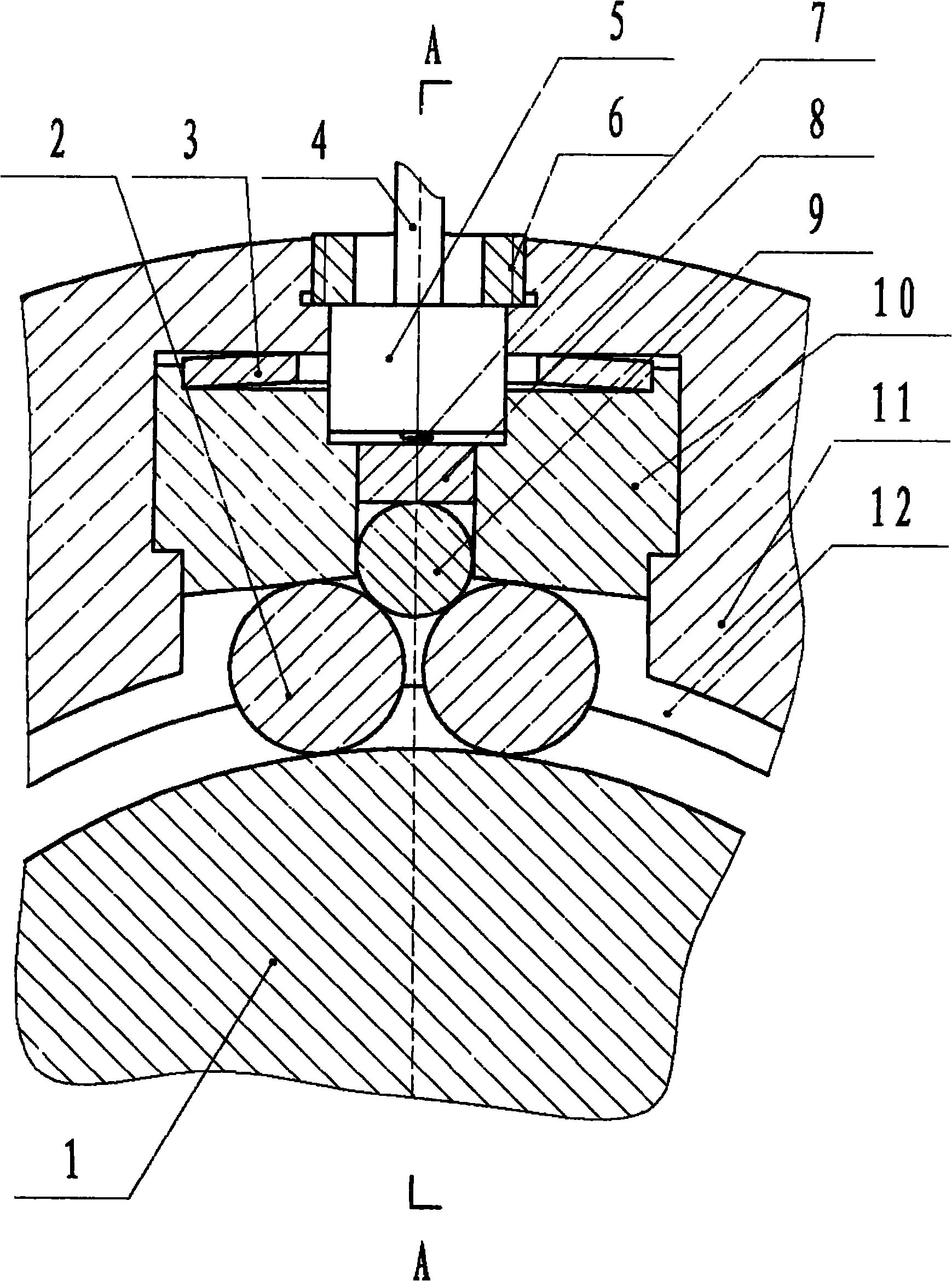

[0021] Below, the present invention will be further described in detail in conjunction with the accompanying drawings. exist figure 1 , figure 2 As can be seen in the figure, there is a roller type overrunning clutch mechanism in which the star wheel is an outer star wheel, and the feature is that the spring installed on the outer star wheel 11 in the roller type overrunning clutch mechanism in which the star wheel is an outer star wheel The pin ejector mechanism is removed, and a device installed near the position of the original spring pin ejector mechanism can perform constrained movement along the radial direction of the outer star wheel 11 and can tighten the roller 2 in the mechanism under the action of an operable external force. On the working position, the cylindrical roller top post 9 that can be disengaged from the roller 2 under the action of an operable external force is substituted.

[0022] In a roller mechanical brake, the working surfaces of the roller top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com