Panel of indoor air conditioner and production method thereof

A technology for air-conditioning indoor units and panels, which is applied to other household appliances, heating and ventilation covers/covers, flat products, etc., and can solve problems such as easy wear of panels, difficult positioning of protective films, and poor viewing, and achieve easy and accurate positioning , enhance ornamental, good hand feeling effect

Inactive Publication Date: 2010-09-15

FUJIAN RICHES ELECTRONICS SCI & TECH

View PDF6 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention provides a panel of an air conditioner indoor unit, which aims to overcome the problems that the surface of the panel of the traditional air conditioner indoor unit is easy to wear and the panel of the existing air conditioner indoor unit has poor ornamental quality caused by "leaking". Another purpose of the invention is to overcome the problem of difficult positioning of the protective film in the injection molding process in the existing production method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Unilateral width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Login to View More

Abstract

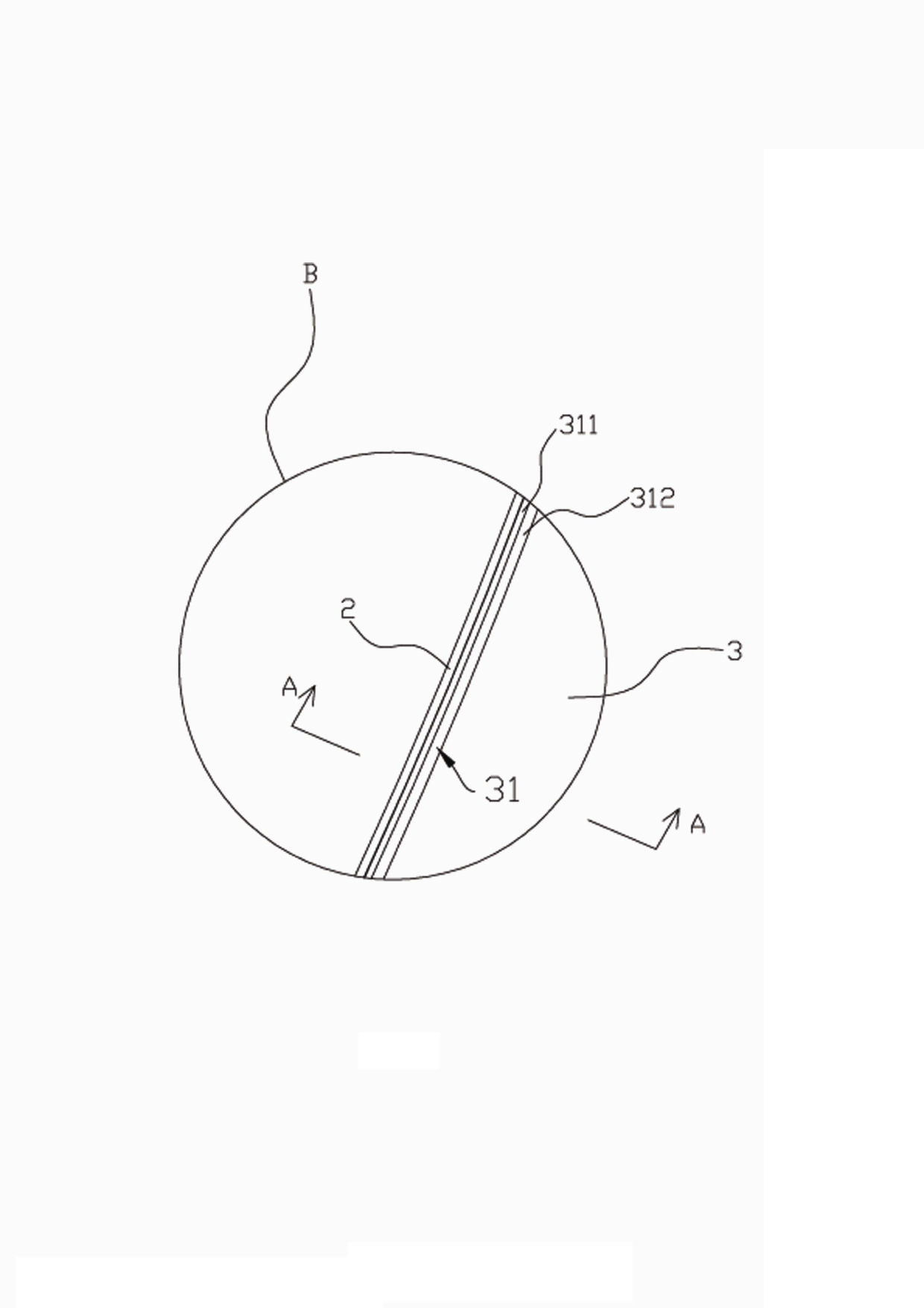

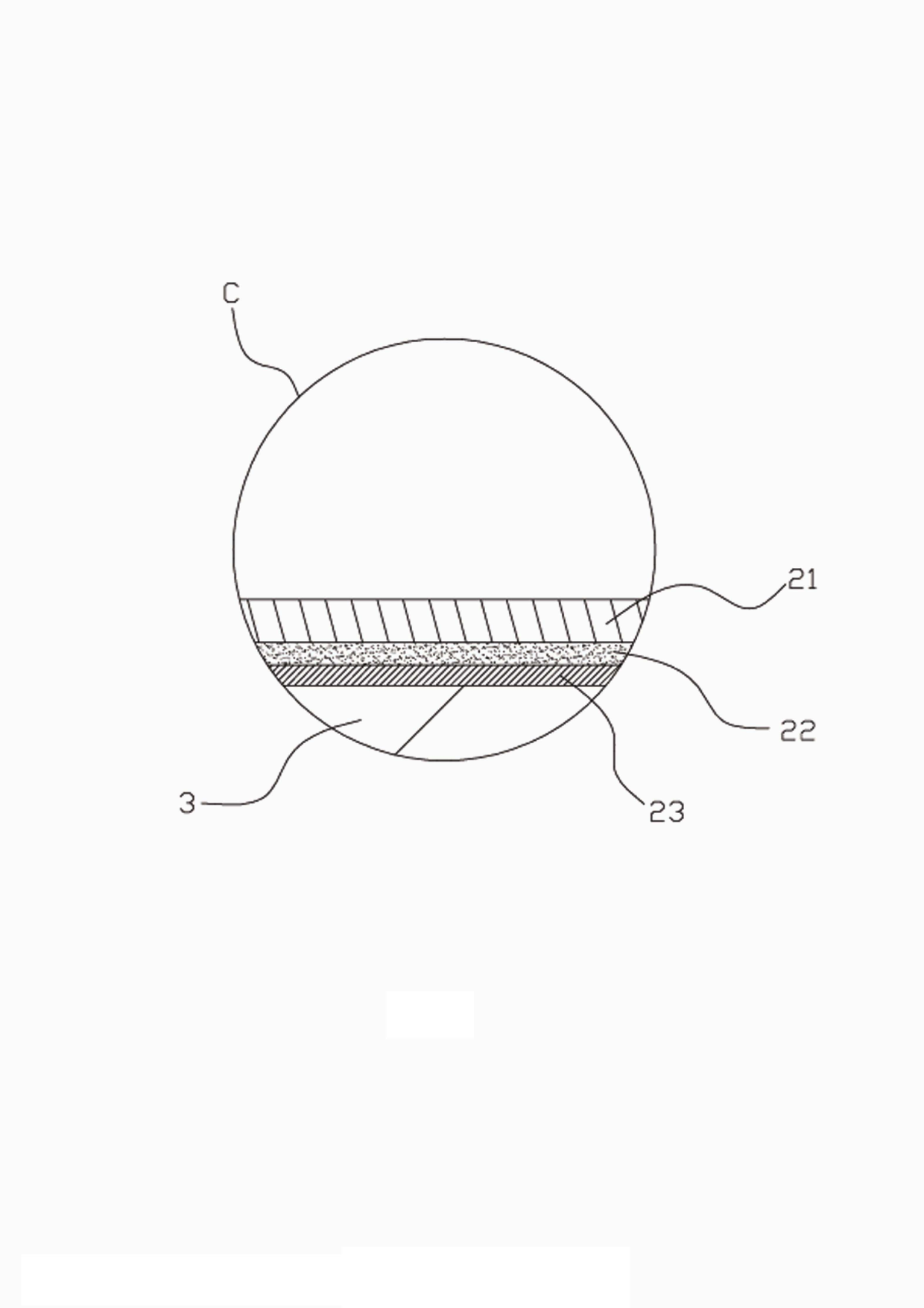

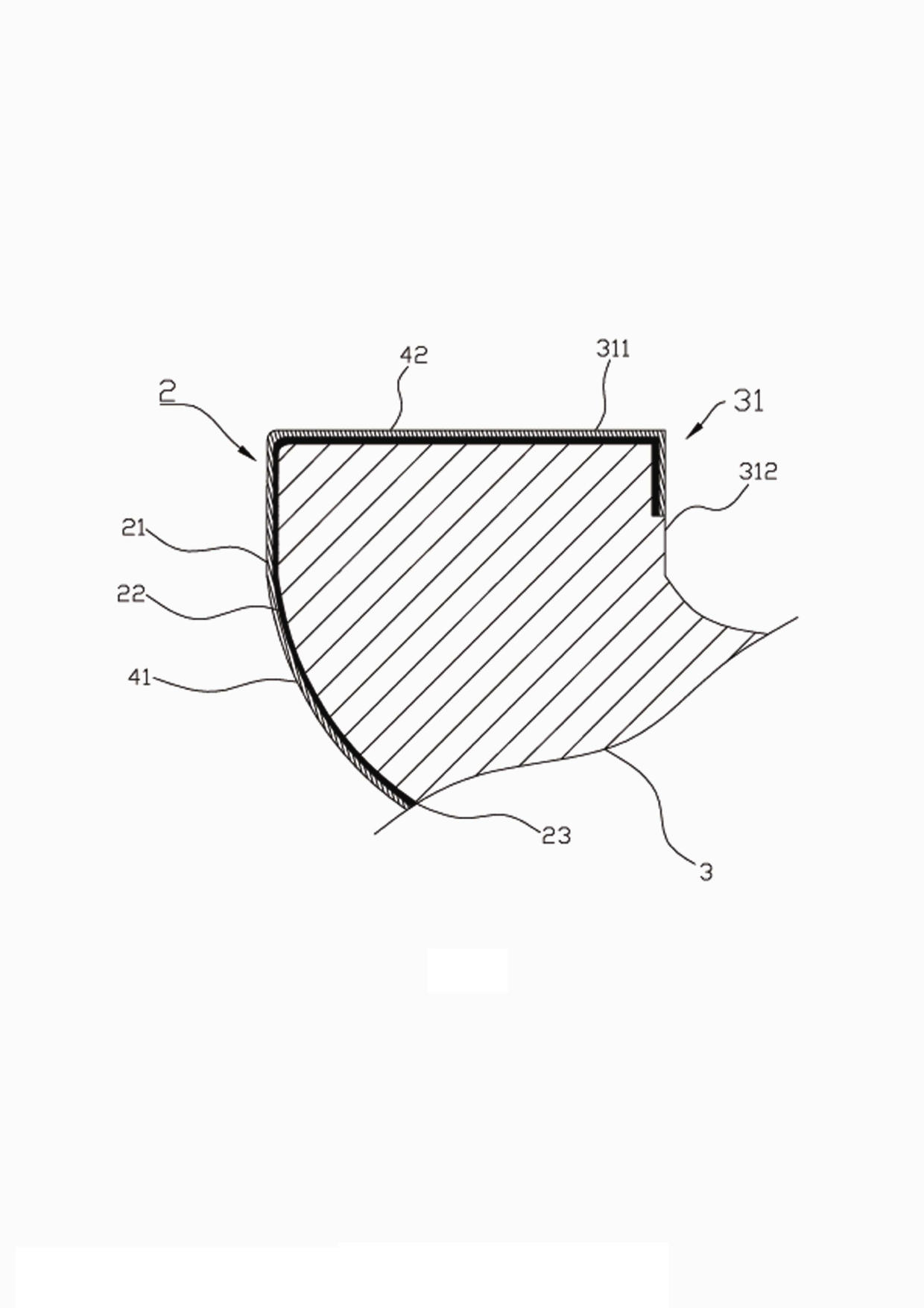

The invention discloses a panel of an indoor air conditioner, which, from the exterior to the interior, comprises a thin film layer and a plastic layer subjected to injection molding on the internal surface of the thin film layer, wherein the thin film layer, from the exterior to the interior, comprises a transparent PET film, an ink decorative layer printed on the internal surface of the transparent PET film, and a cementing layer printed on the ink decorative layer; moreover, the thin film layer also comprises an external thin film layer and an extension part which is integrally connected with the external thin film layer; and the extension part covers and combines the periphery of the internal surface of the plastic layer. Because the combined edge of the thin film layer and the plastic layer is positioned on the internal surface of the plastic layer, the panel has better ornamentation property, and the thin film layer is not easy to separate from the plastic layer. The invention also discloses a method for producing the panel, which mainly comprises the steps of printing, thermal forming, and injection molding. Because the thin film layer extends to the internal surface of the plastic layer, the method for producing the panel is convenient to accurately position the thin film layer; therefore, the difficulty in the production is reduced, and the rejection rate of the panel is effectively reduced.

Description

Technical field The invention relates to a panel, in particular to an injection molding panel with decorative effect applied to an air conditioner, and also relates to a production method of the panel. Background technique The outermost side of the indoor unit of the air conditioner is generally equipped with a panel, which is mostly an injection-molded panel. With the popularization of the use of air conditioners, consumers have higher and higher individual requirements for air conditioners. This requirement is not only reflected in the overall performance of the air conditioner, but also in the surface pattern and color of the panel of the air conditioner indoor unit. Commercially, the pattern and color of the panel surface are often a big selling point. Generally, air conditioners with rich colors and diverse patterns are easier to sell than traditional air conditioners with a single color and pattern such as silver or gray. In addition, the surface of the panel of the trad...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F24F13/20B29C45/14B29L7/00

Inventor 苏文露田均波

Owner FUJIAN RICHES ELECTRONICS SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com