Thermocouple correcting device and method

A technology of a calibration device and a calibration method, which is applied in the direction of using electric devices, measuring devices, and thermometers using electric/magnetic elements that are directly sensitive to heat, can solve the problems of gas energy consumption, furnace damage, waste, etc., and achieve energy saving , the effect of prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

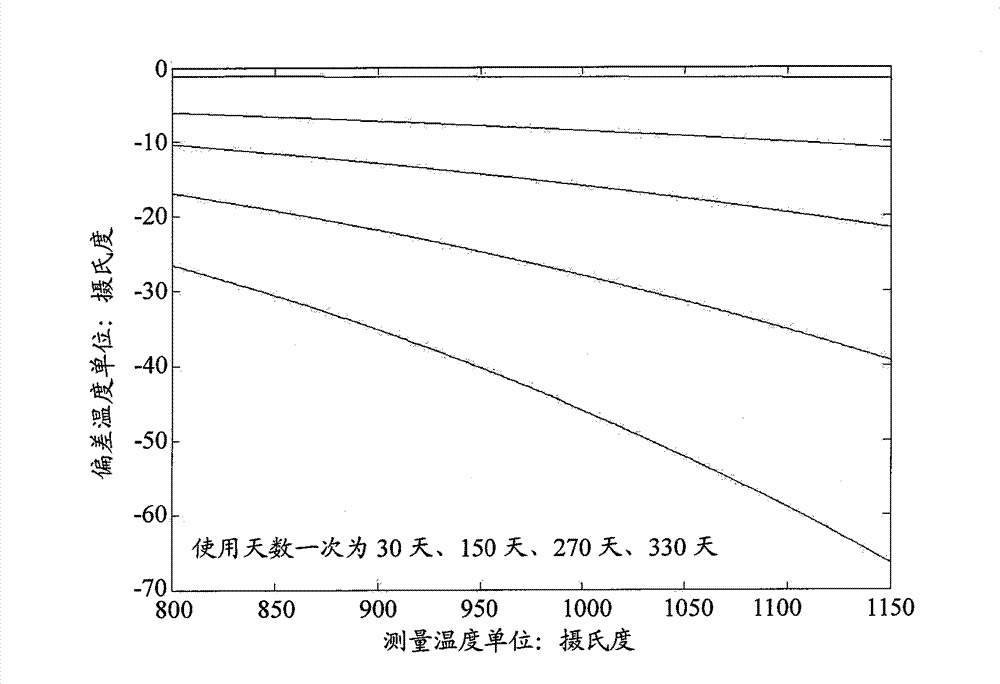

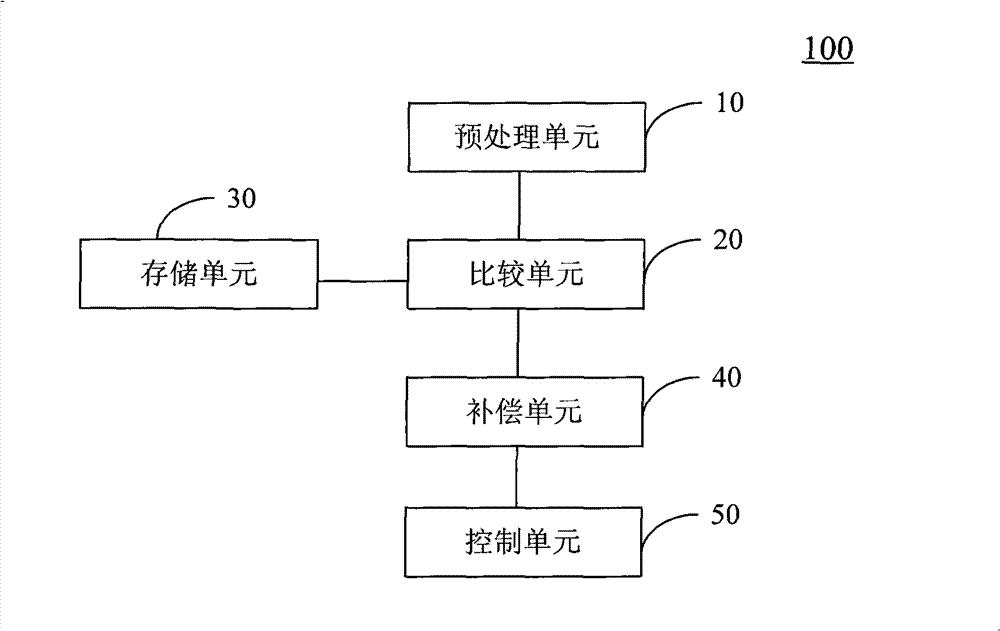

[0022] The following describes a thermocouple calibration device 100 according to an embodiment of the present application with reference to the accompanying drawings. The device can be applied, for example, to a carbon firing system for aluminum or similar occasions.

[0023] Such as figure 1 As shown, the thermocouple calibration device 100 includes a data preprocessing unit 10, and the data preprocessing unit 10 is configured to collect voltage values from one or more thermocouples, such as Seebeck (Seebeck) analog voltage, and convert it into The temperature value that characterizes the raw temperature of the thermocouple.

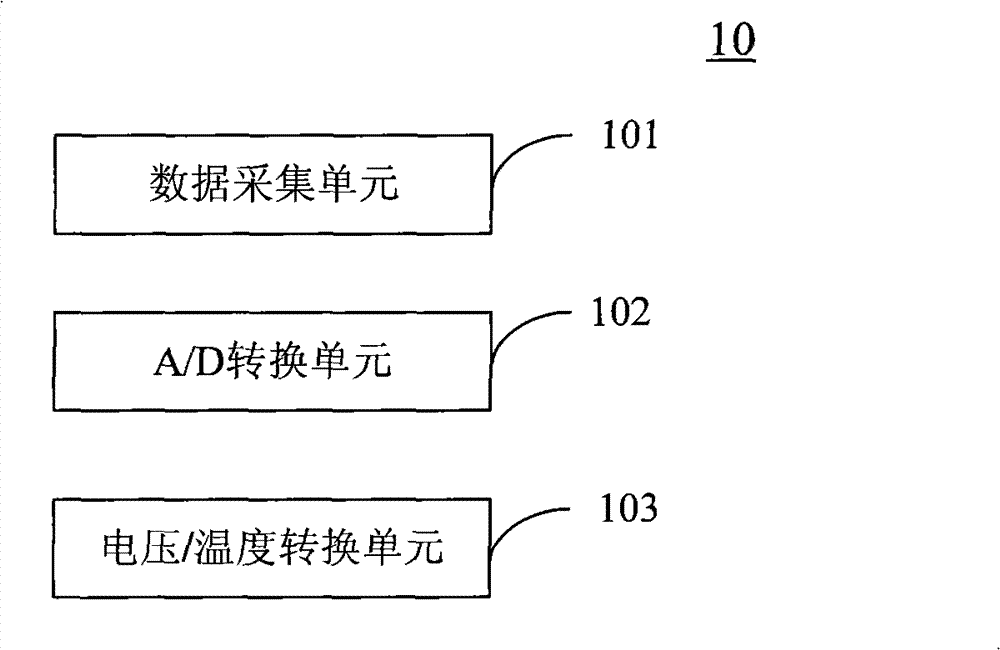

[0024] see figure 2 , which exemplarily illustrates the structure of the data preprocessing unit 10, which may include a data acquisition unit 101, an A / D conversion unit 102, and a voltage-temperature conversion unit 103, wherein the data acquisition unit 101 may be located at One or more thermocouples at the firing site (eg, firing furnace) pick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com