Device for carrying out long-time continuous optical monitoring on liquid concentration

A technology for optical monitoring and liquid concentration, which is applied in measuring devices, color/spectral characteristic measurement, material analysis through optical means, etc. It can solve the problems of poor practicability and applicability, unsuitability for long-term continuous monitoring of liquid concentration, and short calibration period and other problems, to achieve the effect of eliminating the interference of slow-changing factors and continuously monitoring the liquid concentration for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structure of the present invention will be further described below in conjunction with the drawings and embodiments.

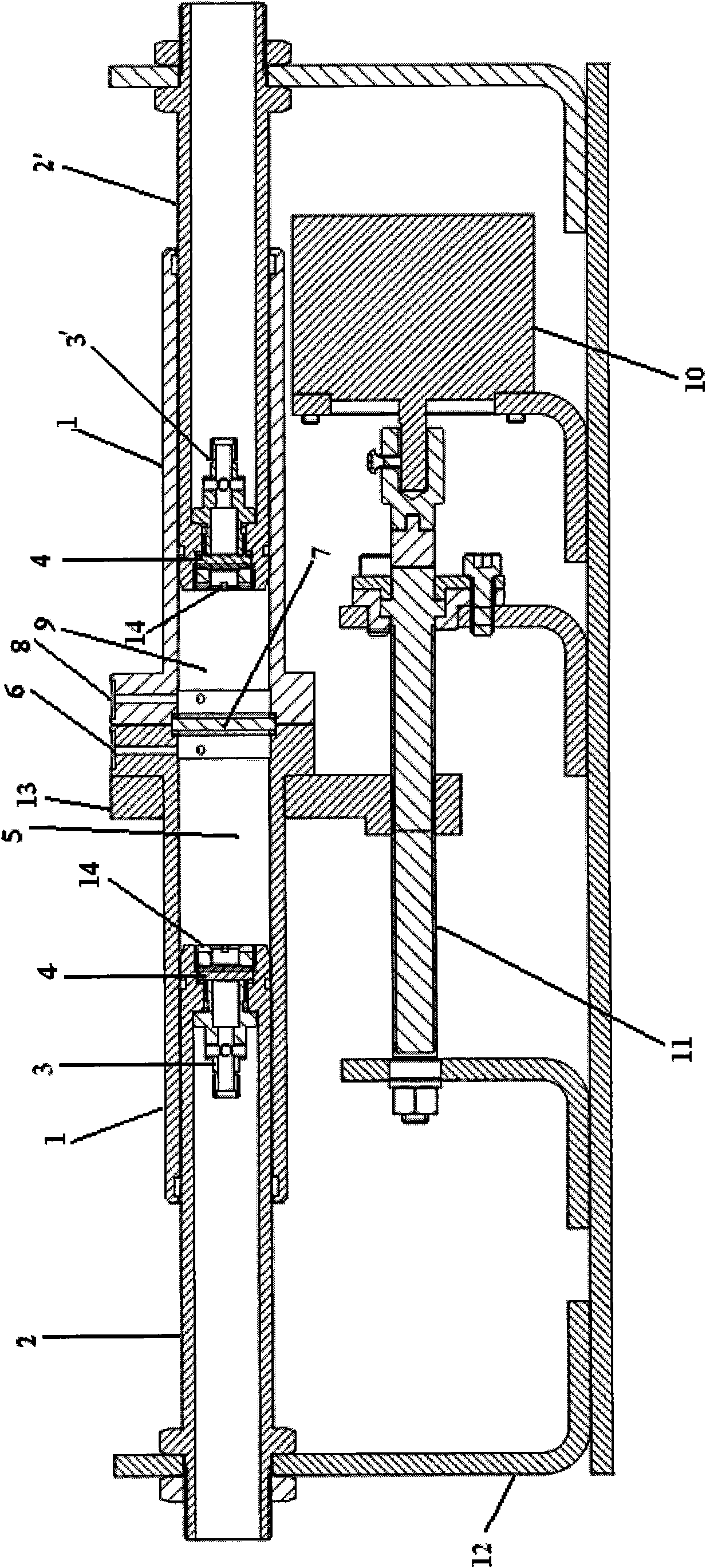

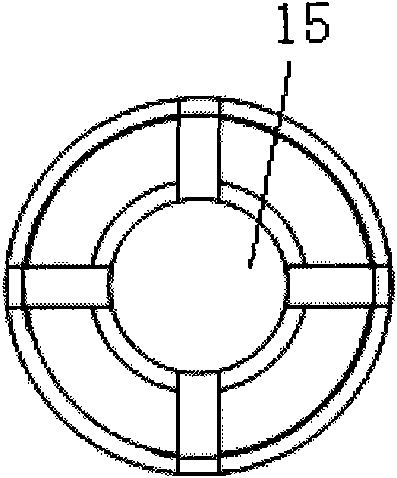

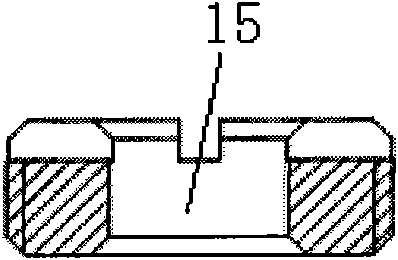

[0021] Such as figure 1 In the device of the present invention shown, the movable sleeve 1 has a cylindrical structure, and the first plunger 2 and the second plunger 2'are partially placed in the movable sleeve 1. The inner diameter of the movable sleeve 1 is matched with the outer diameters of the first plunger 2 and the second plunger 2', so that the first plunger 2 and the second plunger 2'can be connected to the movable sleeve through a ○-shaped sealing ring. 1 forms a dynamic seal, and a fixed cavity is enclosed between the movable sleeve 1 and the first plunger 2 and the second plunger 2'.

[0022] The transparent lens 7 is sealed and fixed in the movable sleeve 1, so that the first plunger 2 and the second plunger 2'are respectively located on both sides of the transparent lens 7, thereby connecting the movable sleeve 1 with the first plunger 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com