Infrared detection device applying counter-compensation heat dissipation design

A technology of infrared detection and temperature compensation, applied in measuring devices, installation, optical radiation measurement, etc., can solve the problems of unstable matching accuracy, complex processing technology, large volume, etc., to save energy consumption and raw materials, high processing precision, Excellent compensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

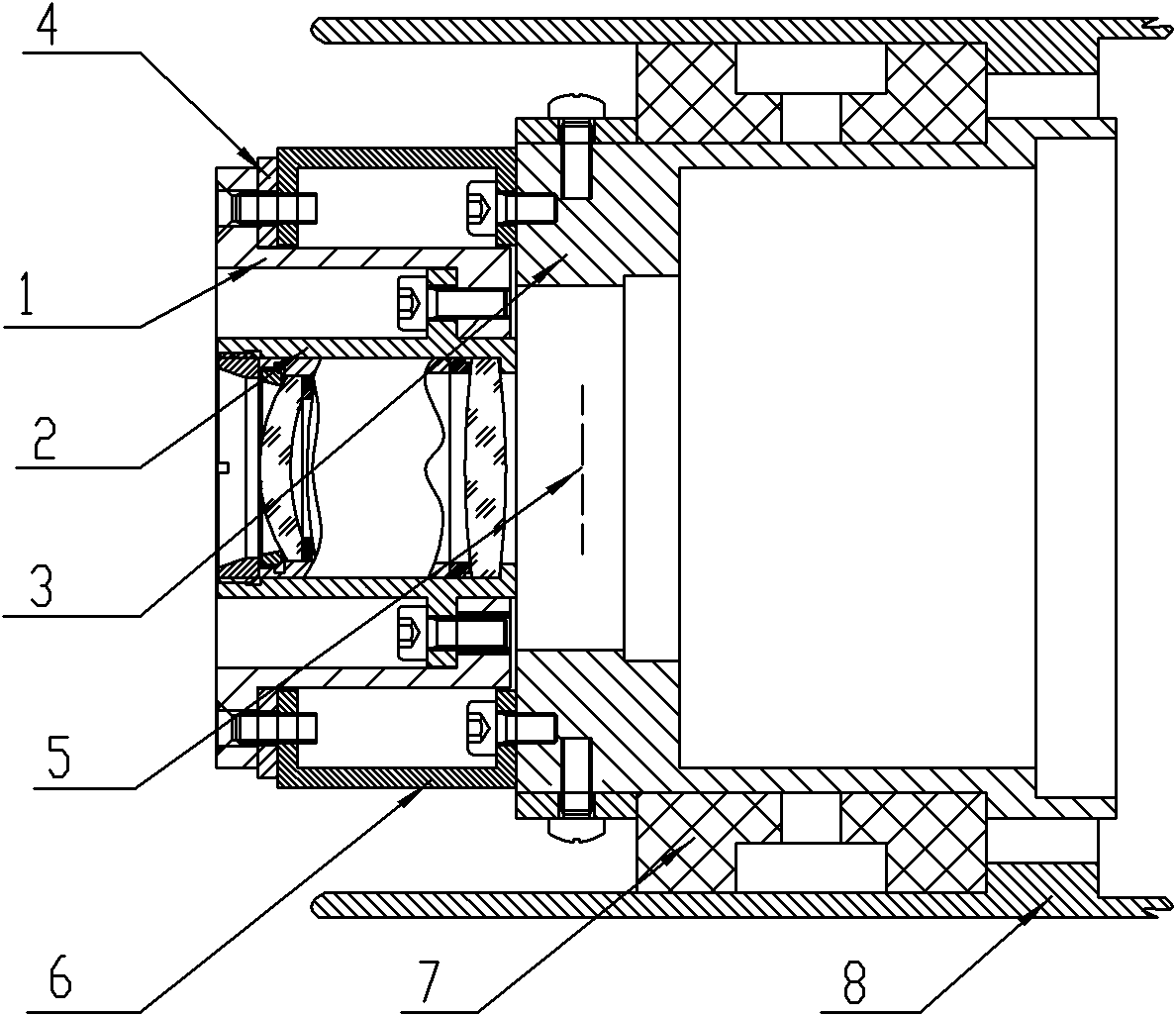

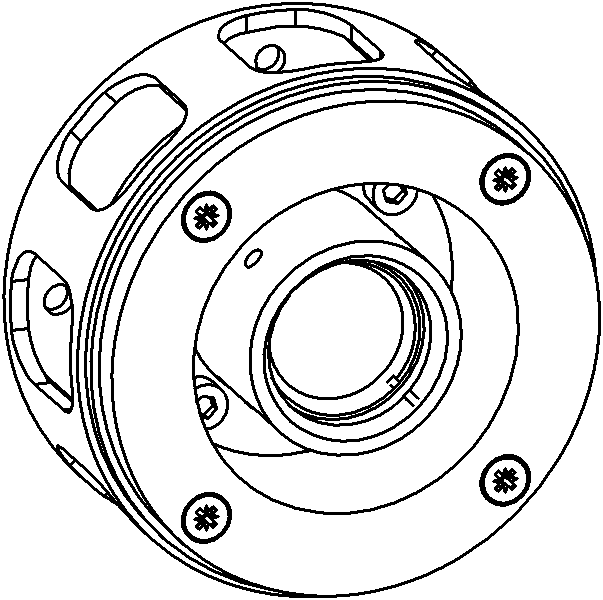

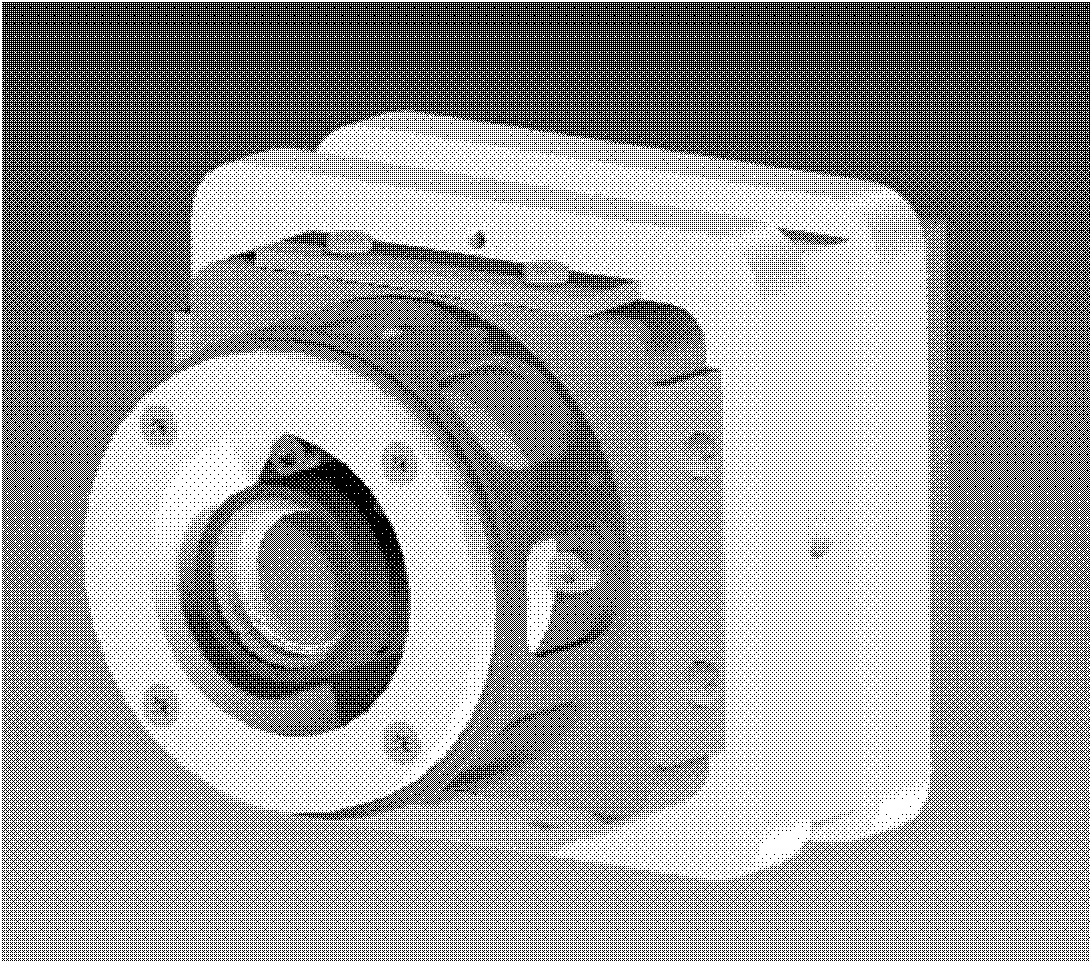

[0023] The present invention adopts the mechanical passive heat dissipation, that is, the structure reverse compensation form, adopts a temperature compensation cylinder, fixes the infrared lens as a whole in the temperature compensation cylinder with screws, and uses the screws and the infrared thermal imager installation frame together with the temperature compensation cylinder The connection surface on the connection. Since the infrared thermal imager is fixed inside the metal with low expansion coefficient, the change of its focal plane position is very small and negligible. The axial movement of the infrared optical system image plane position is realized by relying on the axial movement caused by the temperature change of the temperature compensation cylinder. compensate.

[0024] The traditionally applied mechanical passive heat dissipation design is to install one or several groups of lenses that need to be moved on the guide rail, and connect them to the shell through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com