Method for compensating system in real time by using hysteresis inversion model

A technology of hysteresis model and inverse model, applied in the field of control, can solve the problem of not being able to model the hysteresis curve well, and achieve the effect of simple form and few parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

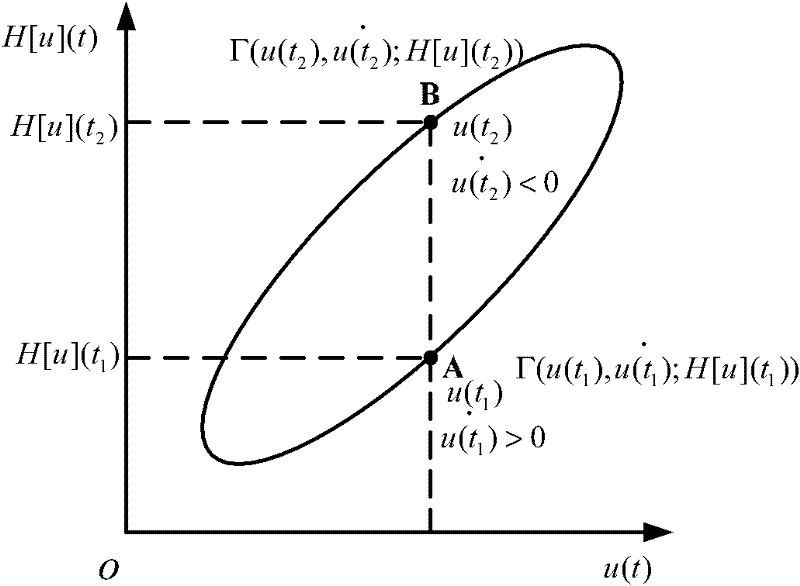

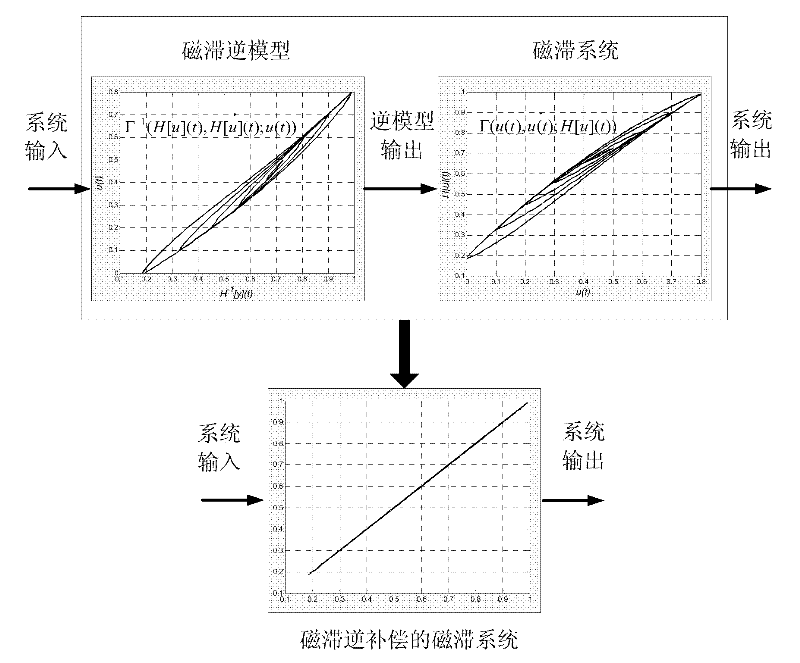

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

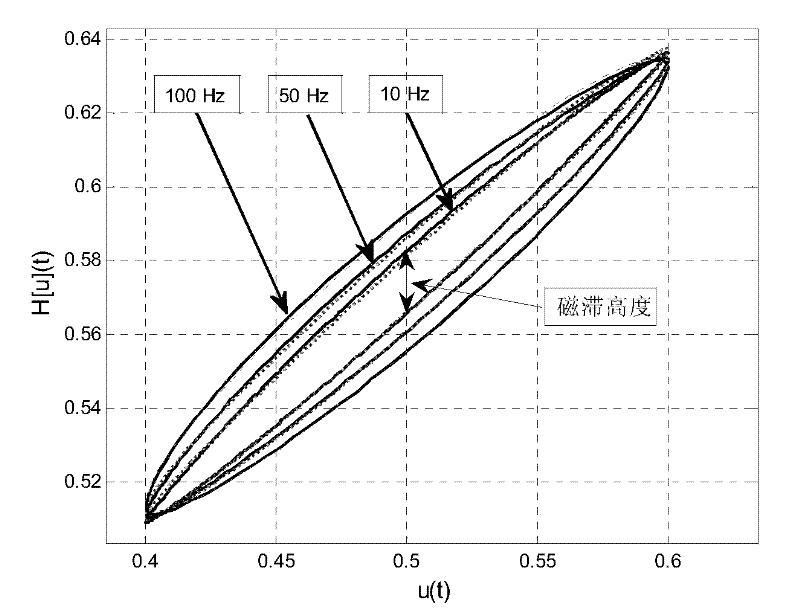

[0037] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, taking the piezoelectric ceramic driver as an example, the detailed implementation and specific operation process are given below, But the scope of protection of the present invention is not limited to the following examples.

[0038] This embodiment is carried out on a self-designed nano-positioning platform driven by a single-degree-of-freedom flexible hinge. The positioning platform is excited by a closed-loop piezoelectric ceramic driver. The piezoelectric material has hysteresis nonlinear characteristics. Therefore, the piezoelectric material of this embodiment The ceramic drive system is a hysteresis system.

[0039] Build a hysteresis system experiment platform with dSPACE-DS1103 (real-time online simulation system) as the core, the main component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com