Three-section vibration motor eccentric block vibrator

A technology of vibrating motor and vibrating device, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of inability to adjust the excitation force, unable to meet the needs of production, and easy damage of the motor, so as to avoid relative position changes and ensure The effect of normal work and high adjustment precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0039] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

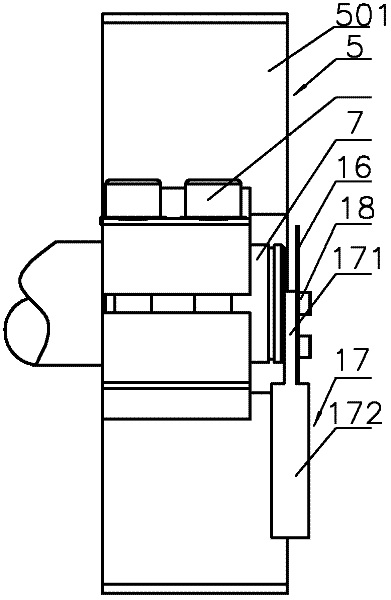

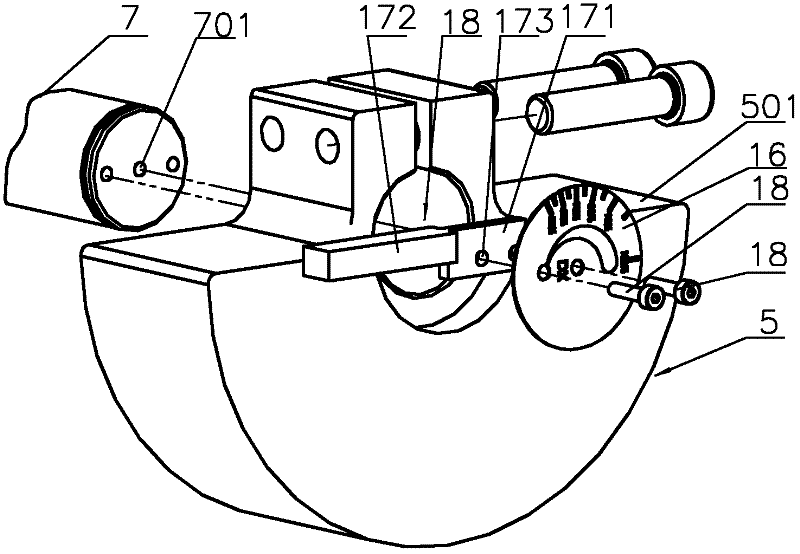

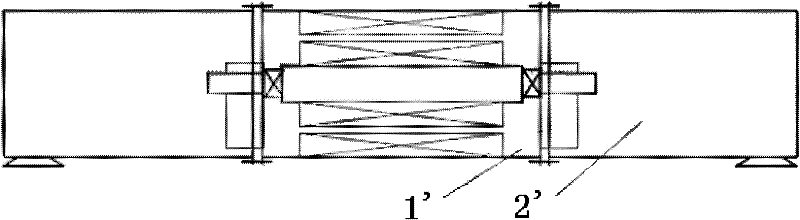

[0040] Such as Figure 4 , 5 As shown, the present invention includes an explosion-proof motor 6 with an overhanging motor main shaft 601, a fixed eccentric block 4, an adjustable eccentric block 5, a housing 1 with a housing cavity for the explosion-proof motor 6, and symmetrically arranged on both sides of the housing 1. The machine base 2 and the two ends of the motor main shaft 601 are respectively connected to one end of the two eccentric shafts 7 provided with a fixed eccentric block 4 and an adjustable eccentric block 5 through a soft coupling 3, and the other end of the eccentric shaft 7 is passed through a bearing and a bearing that is outside the bearing The seat 10 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com