Zinc electrolyte cooling acid mist treatment tower

A technology of zinc electrolyte and treatment tower, which is applied in the field of cooling towers, can solve the problems of hot and humid acid gas polluting the environment, and achieve the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

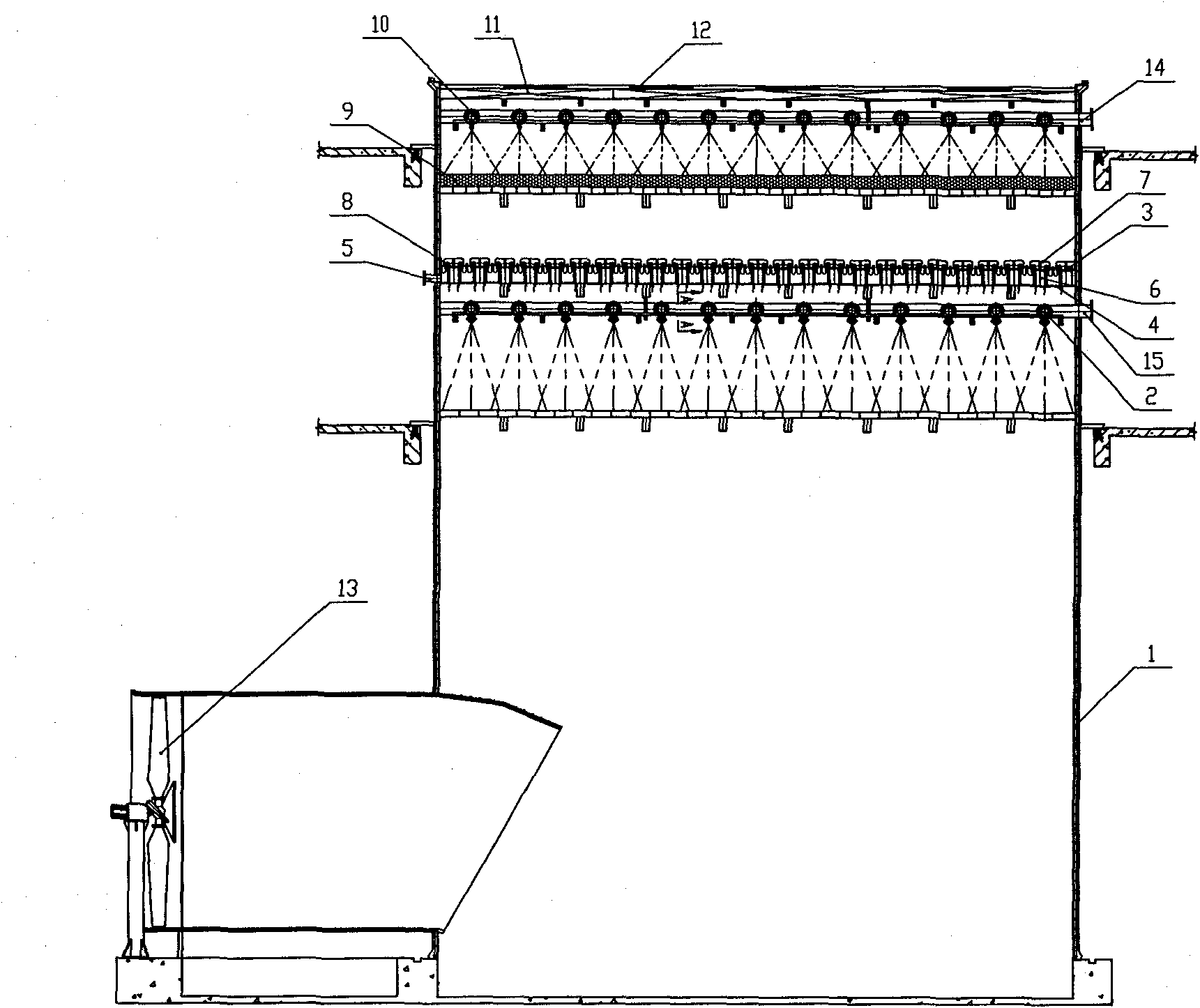

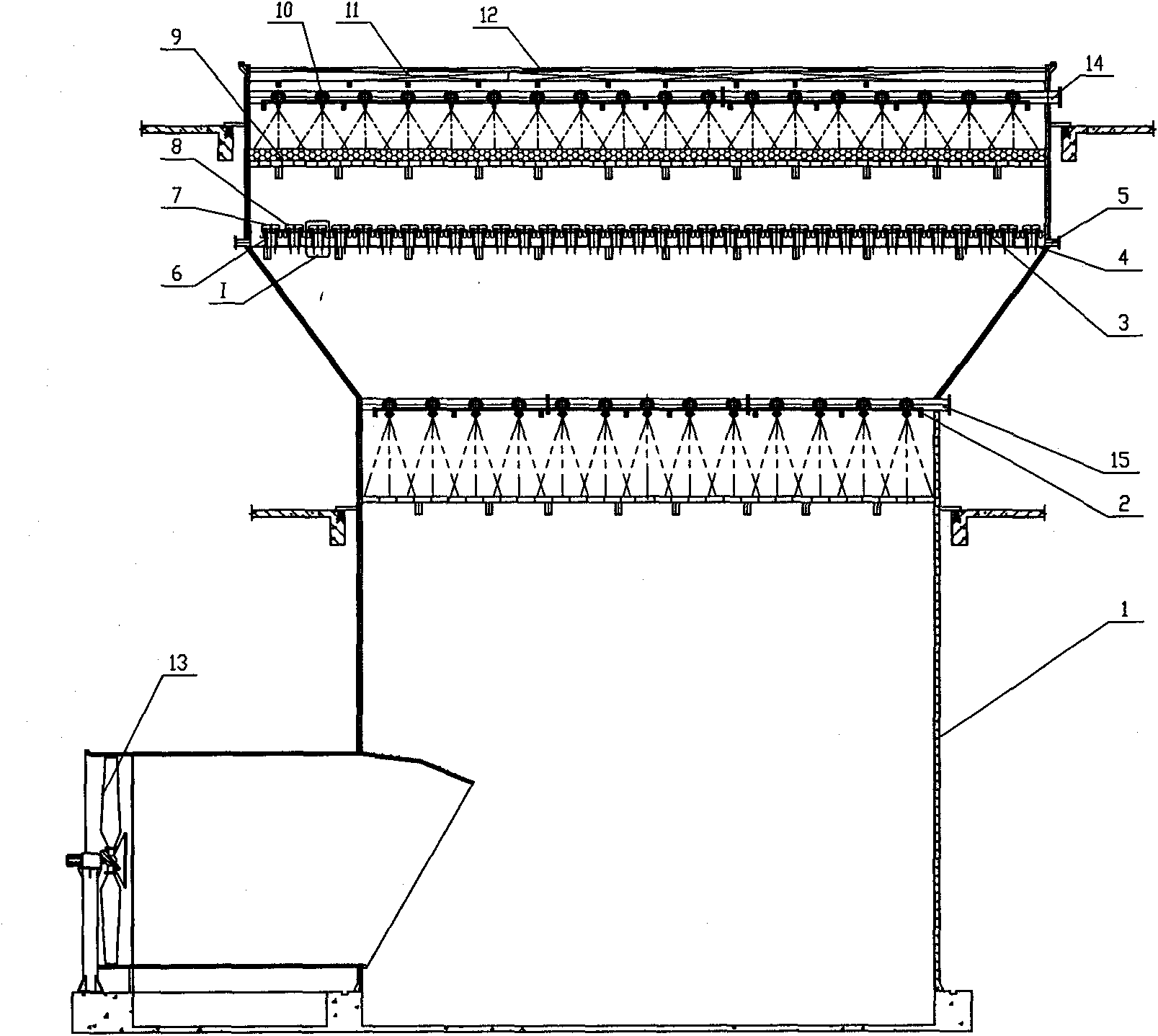

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

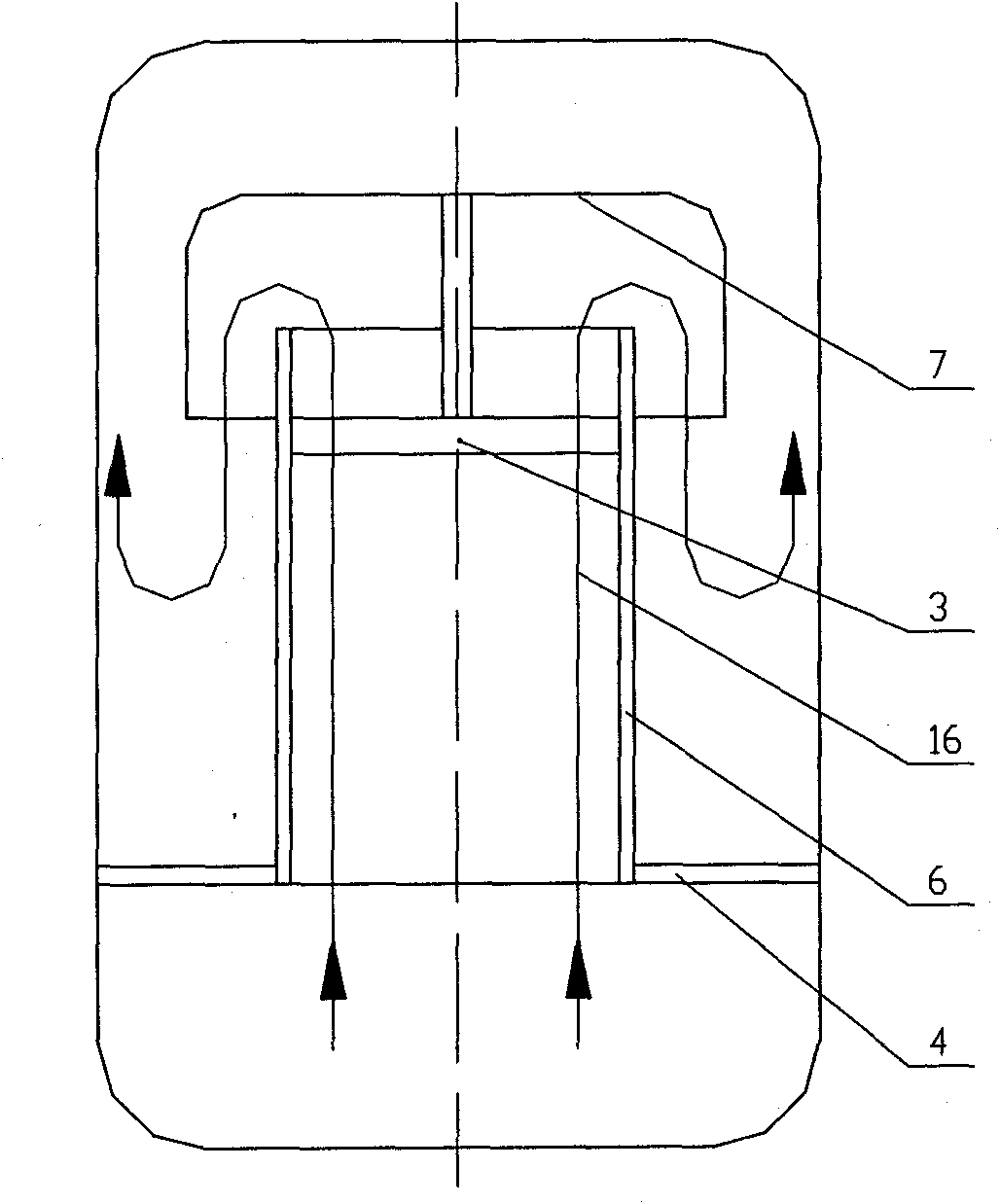

[0013] Such as figure 1 The first embodiment of the zinc electrolyte cooling acid mist treatment tower of the present invention shown has a tower body 1, and a circulating liquid spraying device 2 is housed in the tower body 1, and is located at the center of the circulating liquid spraying device 2 in the tower body 1. There is a liquid-collecting partition 4 that separates the tower body in the horizontal direction above the liquid-collecting partition 4. There is a neutralizing liquid outlet 5 near the liquid-collecting partition 4 on the tower body 1 above the liquid-collecting partition 4. There are several One can make the gas below the liquid collecting partition 4 flow to the vent pipe 6 above the liquid collecting partition 4, each vent pipe 6 is respectively provided with a liquid blocking cap 7, and the upper part of the vent pipe 6 is welded to an inverted "...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com