Sterile waterline system cleaning in place (CIP) pipeline converter plate

A conversion plate and pipeline technology, applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of high cost and inconvenient use, and achieve the effect of saving manufacturing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

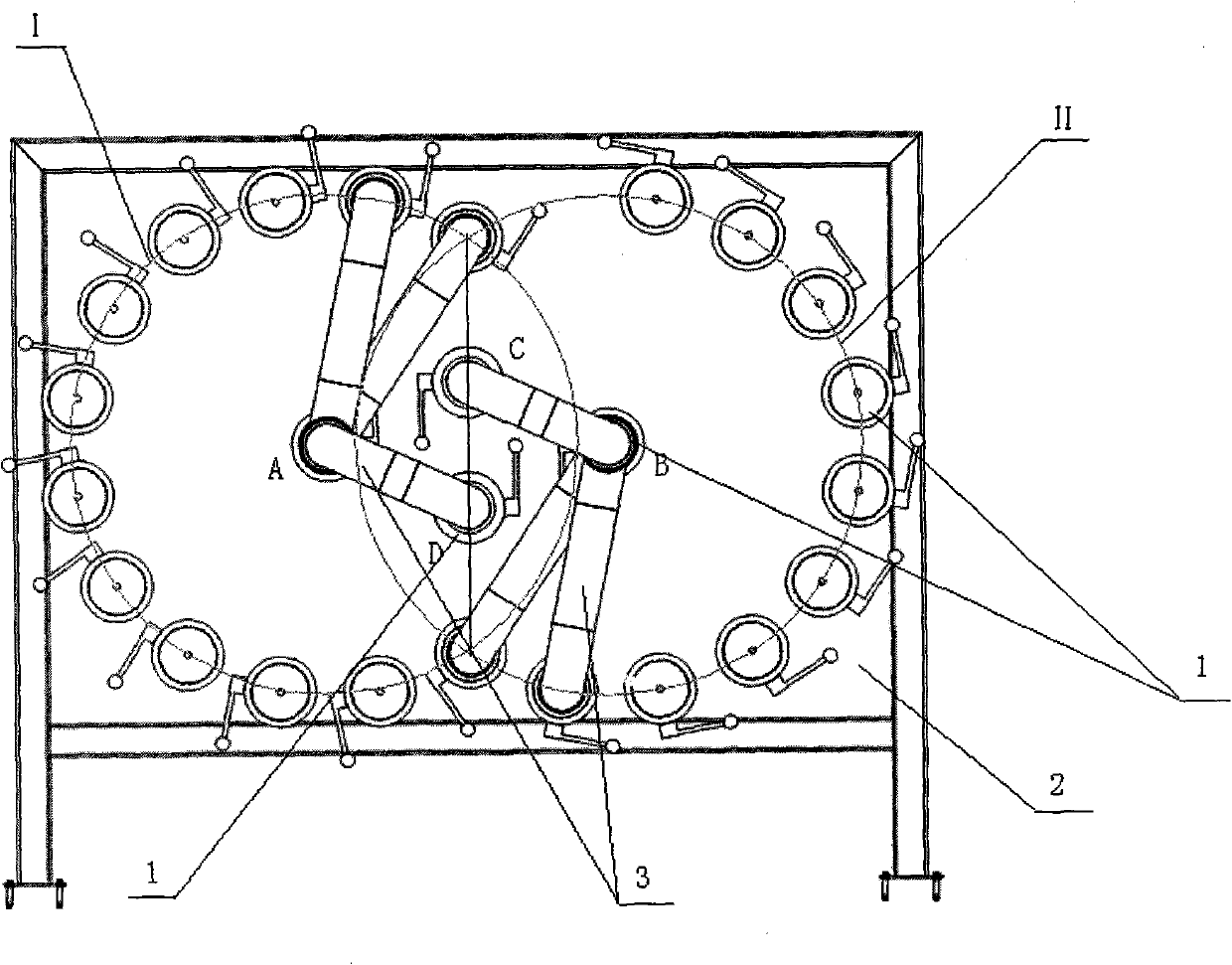

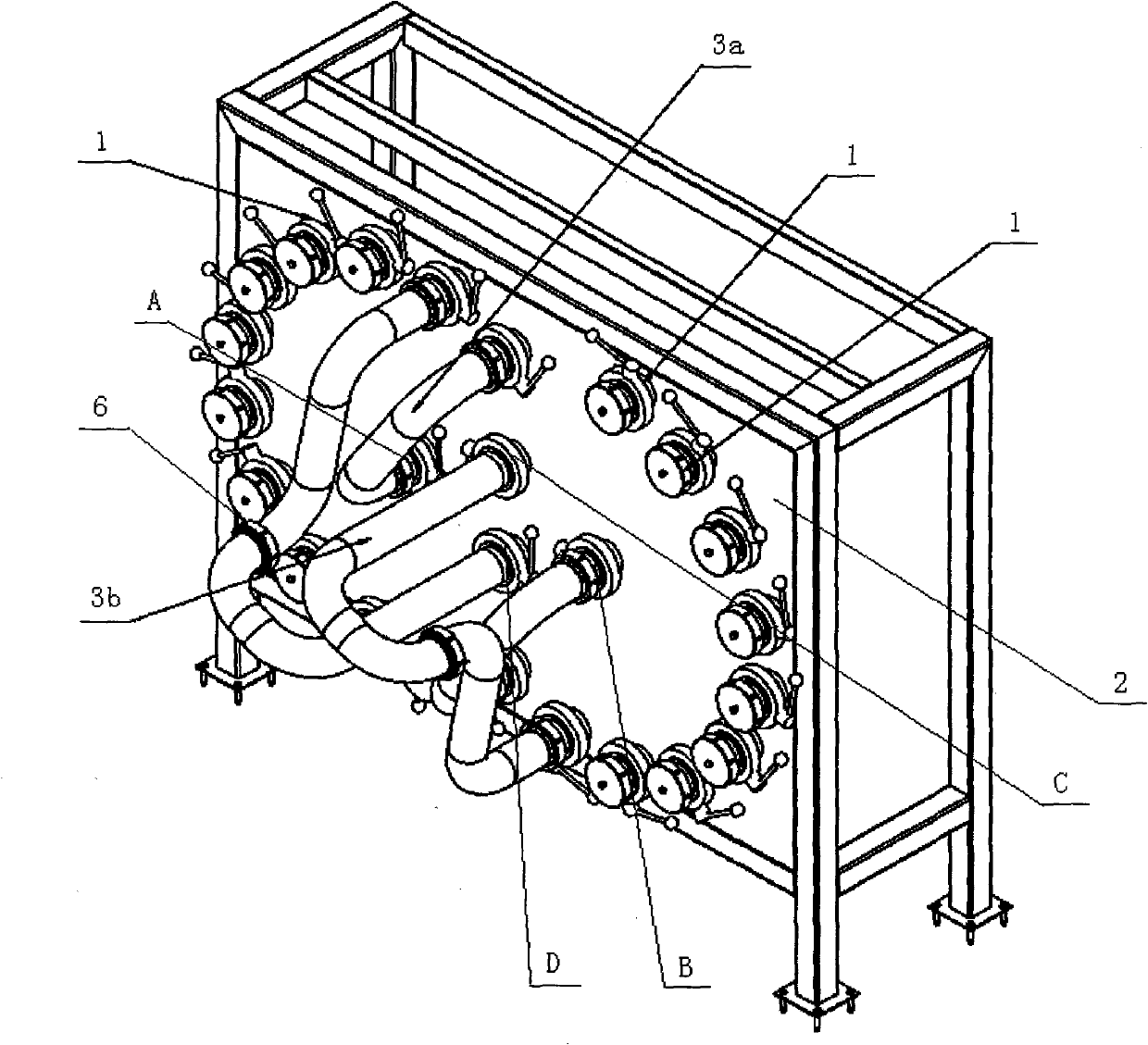

[0019] see figure 2 and image 3 , the aseptic water line CIP pipeline conversion plate of the present invention is provided with twenty-five pipe joints 1 on the frame 2, and the twenty-five pipe joints 1 are two overlapping circles I and circle II with the same radius Arranged on the frame 2, a pipe interface A is set at the center of circle I, a pipe interface B is set at the center of circle II, and two pipe interfaces are symmetrically arranged on both sides of the center of the intersection of circle I and circle II, that is, the pipe Port C and pipe port D.

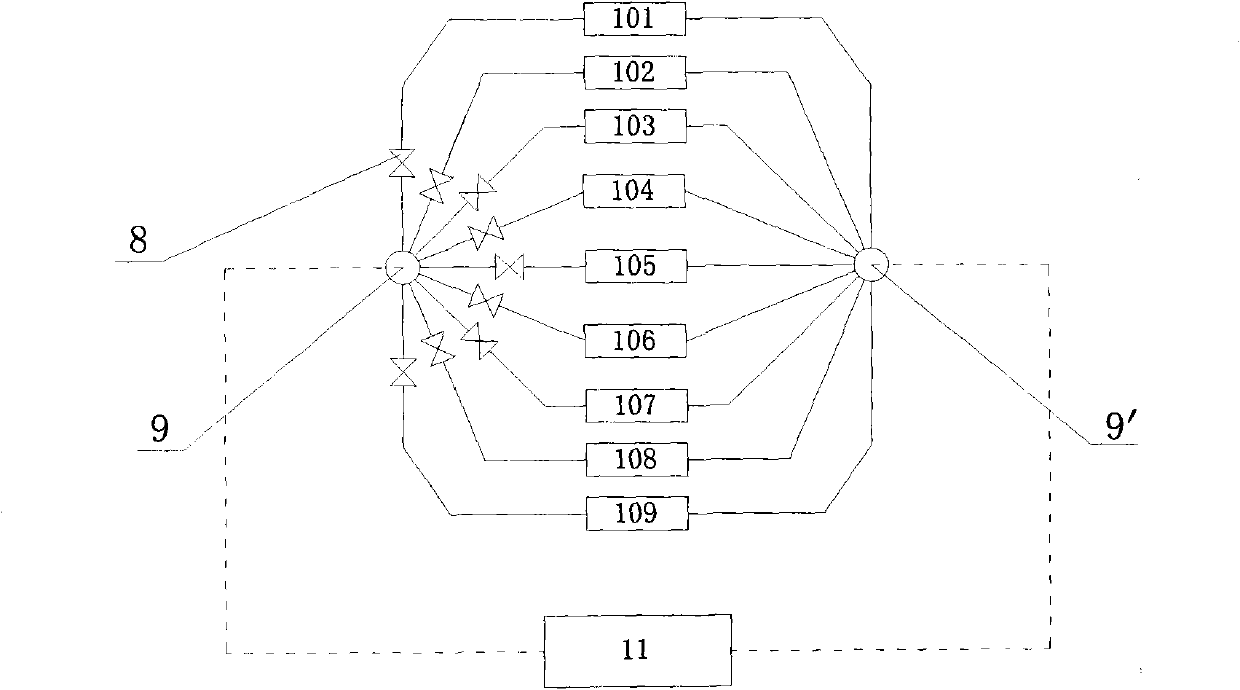

[0020] There are four connecting pipes 3, which are of two types, namely two connecting pipes 3a and two connecting pipes 3b. Pipe connection A is connected to any other pipe connection 1 on circle I through the first connecting pipe 3a; pipe connection B is connected to any ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com