Transmission device capable of converting straight line movement into rotating movement

A technology of rotary motion and transmission device, which is applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., can solve the problems of large wear between motion pairs, difficult crank and connecting rod mechanism, and inability to achieve fixed-angle rotation, etc. The effect of high transmission efficiency, simple structure and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

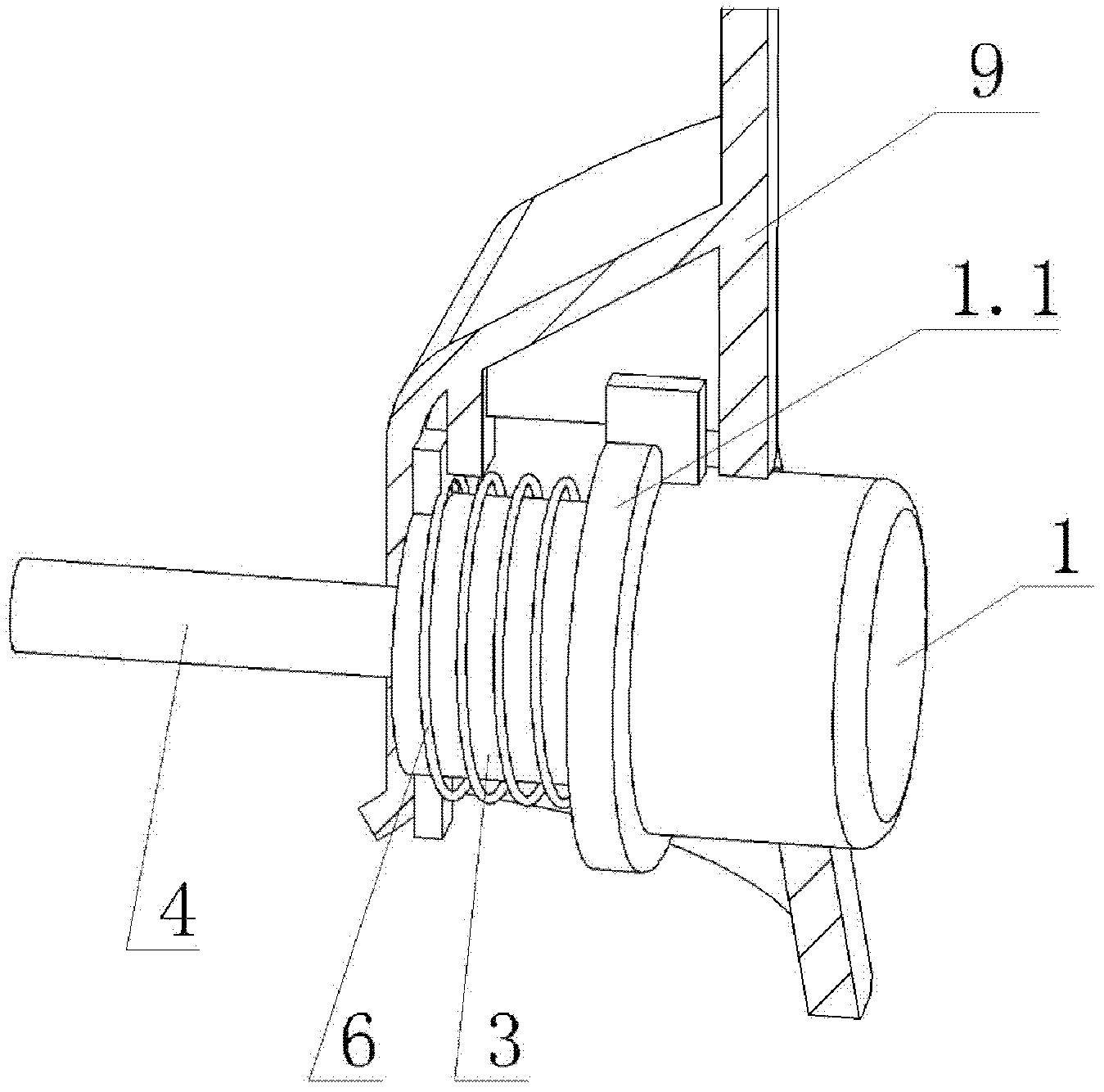

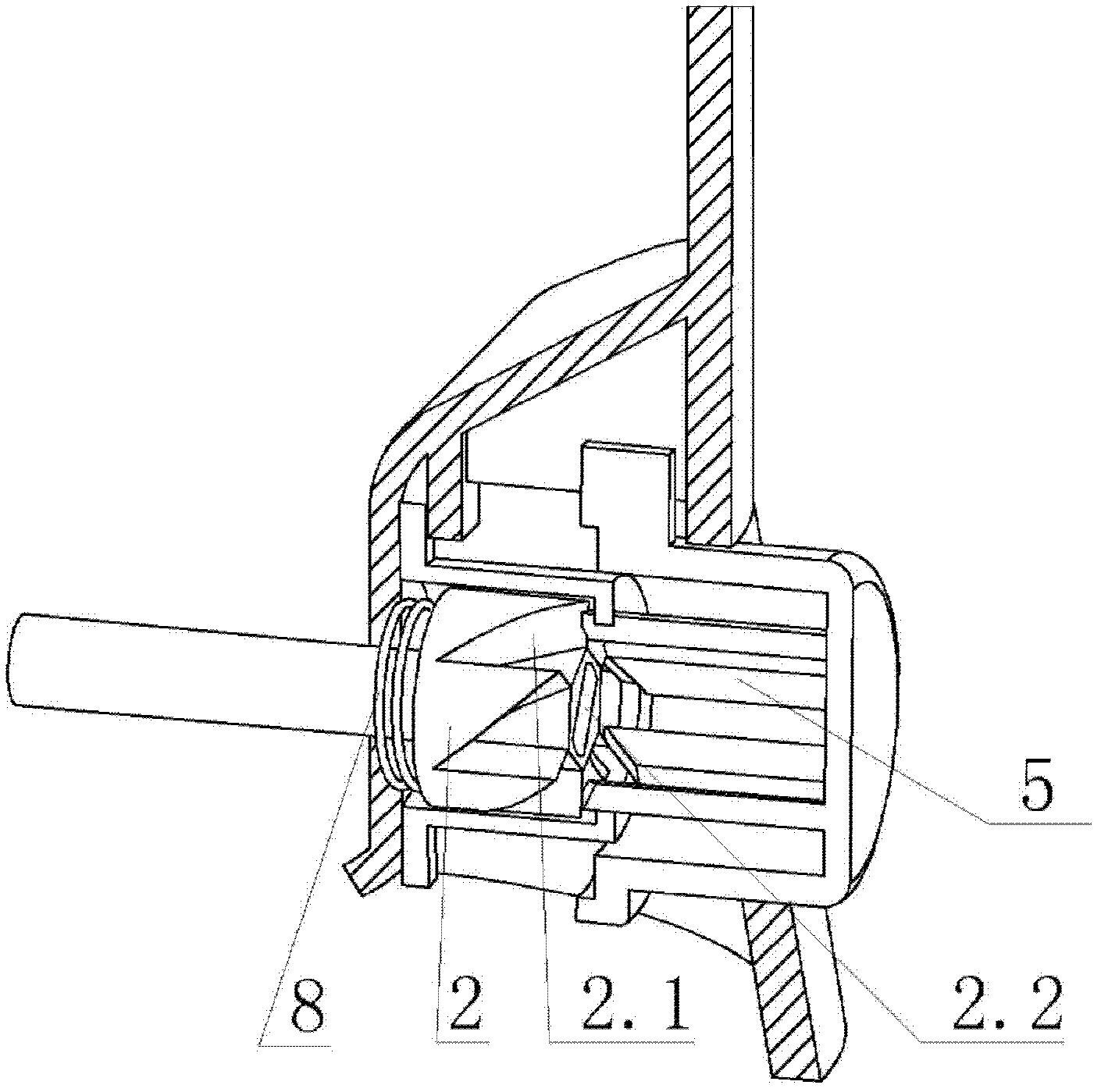

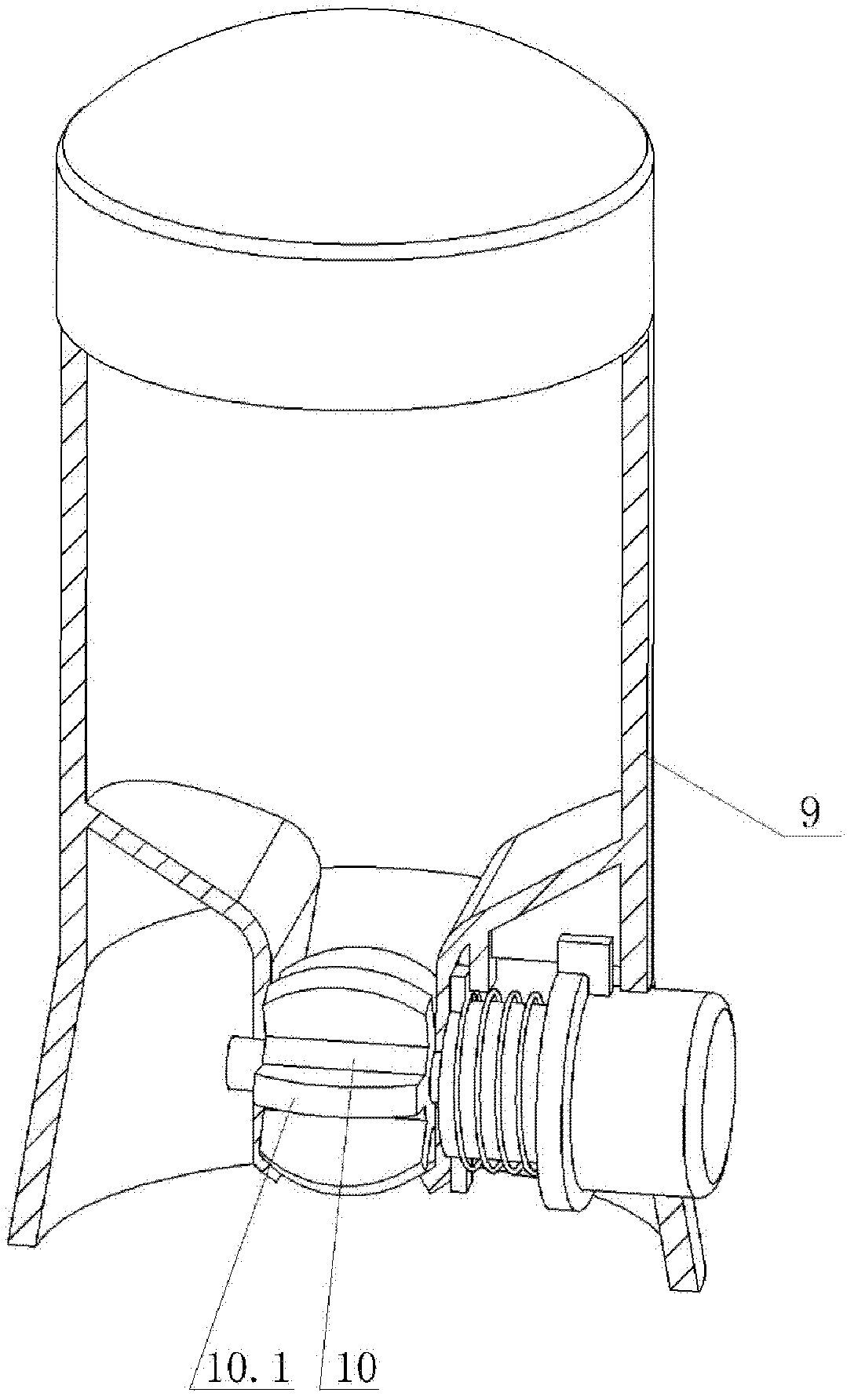

[0021] Such as Figure 1 to Figure 8 As shown, the transmission device for converting linear motion into rotary motion of the present invention includes a push cover 1 for reciprocating linear motion, a rotating core 2 for converting reciprocating linear motion into rotary motion, a rotating sleeve 3, and a rotating shaft 4 for outputting rotary motion .

[0022] The push cover 1 has two or more first extruding blocks 5 with first extruding surfaces 5.1 at the ends of two or more evenly distributed circumferentially. In this embodiment, the number of first extruding blocks 5 is six. The push cover 1 also has a spring 6 for returning. The revolving sleeve 3 is set on the rotating core 2, and the revolving sleeve 2 has a number of second extruding blocks 7 uniformly distributed in its circumferential direction equal to that of the first extrudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com