Air sealing body capable of automatically opening air inlets and manufacturing method thereof

An air-tight body and automatic opening technology, which is applied to hollow objects, other household utensils, and containers to prevent mechanical damage, etc. It can solve the problems that multiple air columns cannot be inflated at the same time, the air passage entrance cannot be opened, and the manufacturing process is cumbersome.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

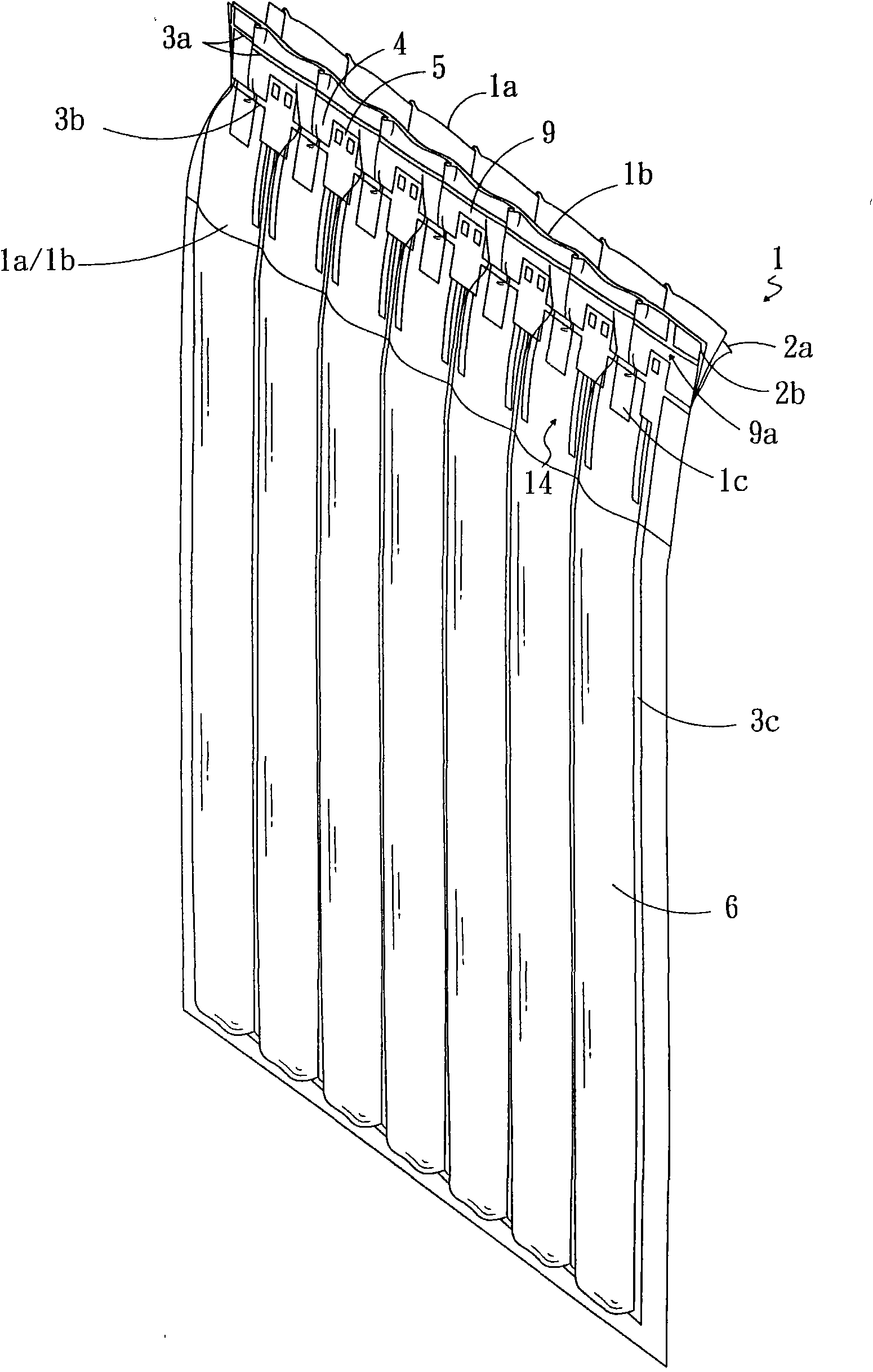

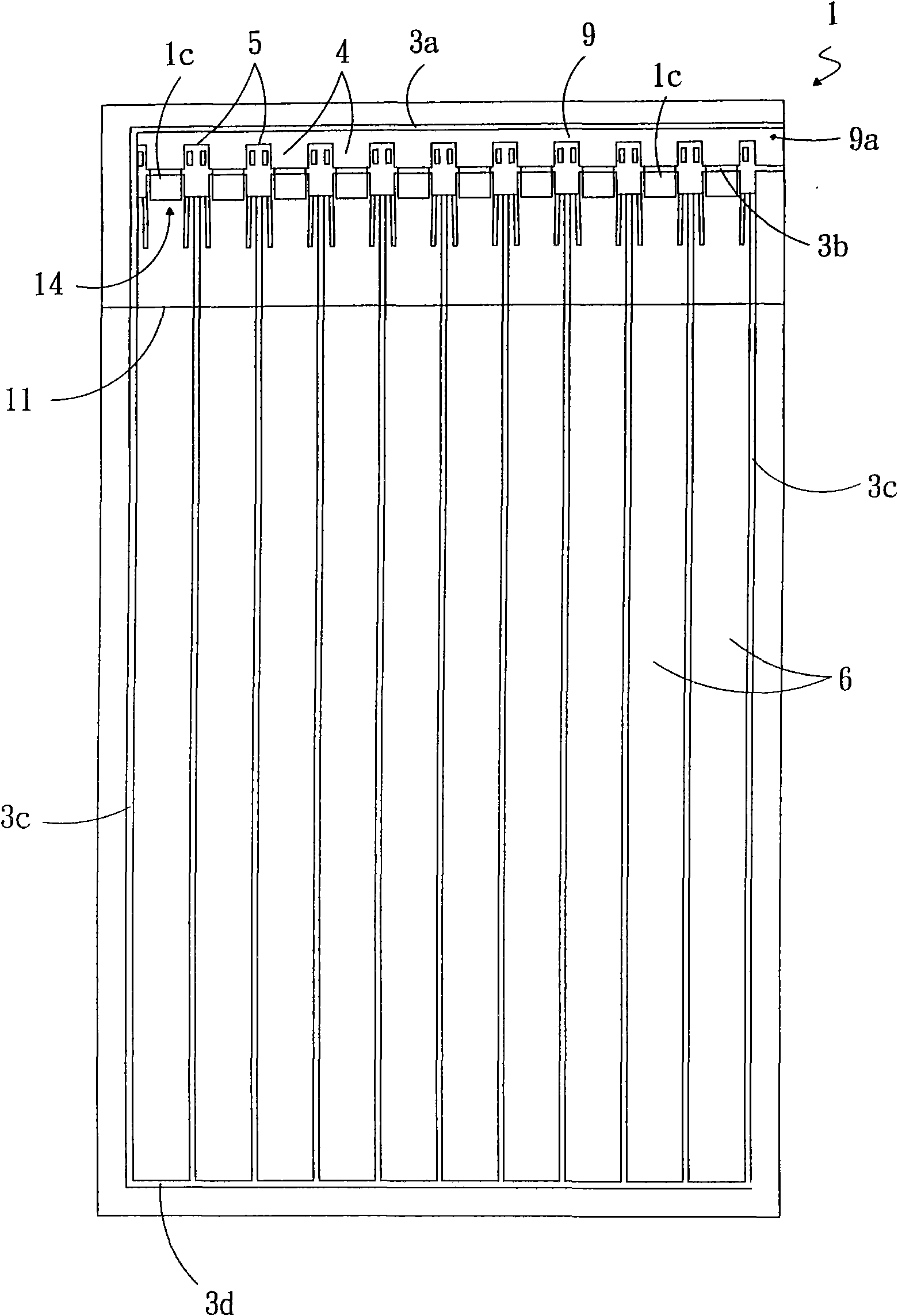

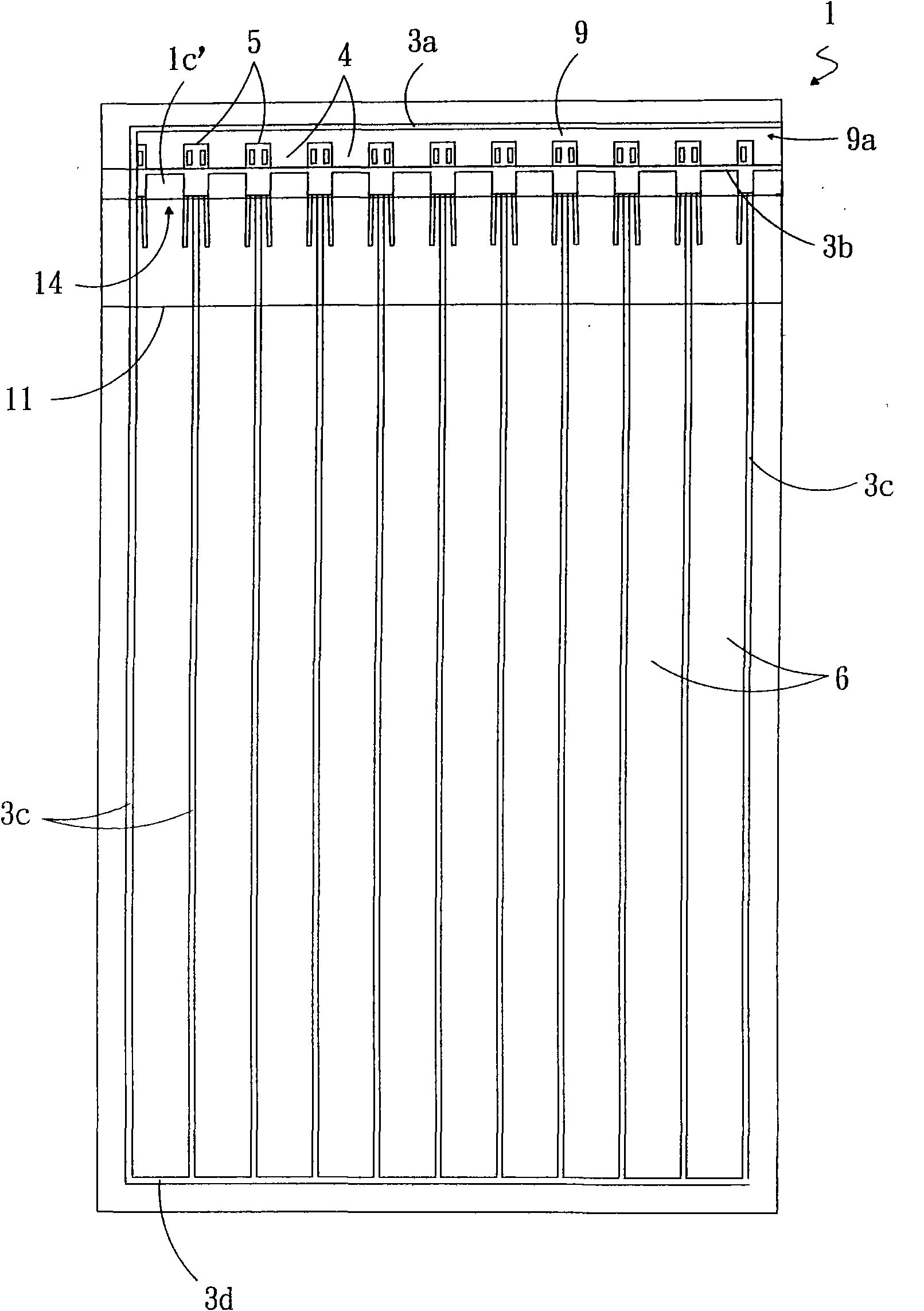

[0037] figure 1 , Figure 2A , Figure 2B , image 3 , Figure 4A , Figure 4B and Figure 5 Shown is a first embodiment of the self-opening air inlet air seal of the present invention.

[0038] The air-tight body 1 of the present invention comprises: two outer membranes 2a and 2b superimposed up and down, two inner membranes 1a and 1b superimposed up and down, heat-resistant material 1c or 1c', an inflatable channel 9, and a plurality of air columns 6 , multiple heat-sealed blocks 5, multiple air-introducing channels 4, and the like.

[0039] The two inner membranes 1a, 1b are between the two outer membranes 2a, 2b, and the tops of the two inner membranes are lower than the tops of the two outer membranes, such as image 3 , the width of the two inner membranes is the same as that of the two outer membranes, and the length of the two inner membranes is shorter than the length of the two outer membranes, Figure 2A The middle number 11 refers to the bottom end of the t...

no. 2 example

[0049] Figure 6A and Figure 6B Shown is a second embodiment of the air seal of the present invention.

[0050] In this embodiment, the heat-sealing block 5 is composed of an air-guiding part 51 and a positioning part 52 connected to each other, and the middle heat-sealing line 3 b is located in the air-guiding part 51 . The heat-sealing block 5 can be quadrangular or elliptical as shown, and can also be circular or polygonal in various shapes, such as rectangle, square, pentagon or hexagon.

[0051] The air guide part 51 is arranged on the inflatable channel 9. When the gas entering the inflatable port 9a expands the inflatable channel 9, the air guide part 51 can guide the gas in the inflatable channel 9 into the air-inducing channel 4 and the air inlet 2e, and can Effectively increase the inflation speed and reduce the inflation time. The positioning part 52 is arranged on the air column and plays a role of positioning the entire heat-sealing block 5 .

no. 3 example

[0053] Figure 7 Shown is a third embodiment of the air seal of the present invention.

[0054] In this embodiment, the heat-sealing block 5 is composed of an air guiding part 51 and a positioning part 52 connected to each other. The positioning part 52 is elongated, and its area is larger than Figure 6A and Figure 6B The area of the positioning part shown in , the area of the positioning part is increased, which can play a better positioning effect on the heat-sealing block. In addition, the area of the positioning portion 52 is also larger than the area of the air guiding portion 51 . The heat-sealing line 3b is located in the positioning portion 52 so that the air inlet 2e is located on both sides of the positioning portion 52. Therefore, in the manufacturing process, even if the positions of the two inner films or the heat-sealing mold deviate, they do not come out of the positioning portion 52. Within the range, two pieces of inner film and two pieces of out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com