Conveyer capable of quantitatively and automatically feeding materials at definite time

An automatic feeding and conveyor technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of only conveying fresh leaf tea, not suitable for tea production lines, lack of quantitative and timing conveying functions, etc., to achieve Significant economic benefits, improved automation, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

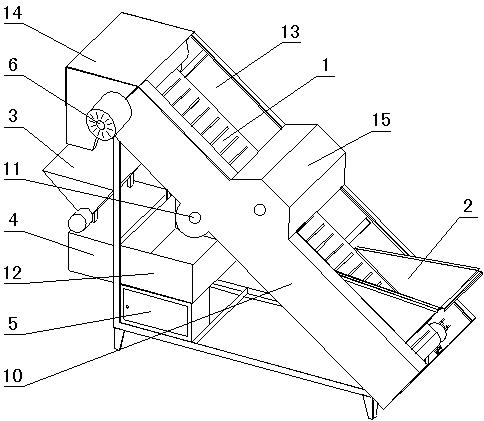

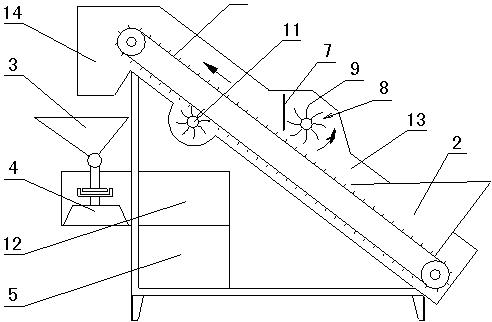

[0025] exist figure 1In the shown embodiment 1, a quantitative and timing automatic feeding conveyor includes a frame 10, a conveyor belt 1 and a control device 5, the conveyor belt is driven by a main motor 6, and the conveyor belt is inclined, and the conveyor belt is low. The end is the feed end, the high end is the discharge end, a fixed hopper 2 is provided above the feed end of the conveyor belt, edge guards 13 are provided above both sides of the conveyor belt, and a discharge guide device 14 is provided at the discharge end. The bottom of the discharge guide device is provided with a rotating hopper 3, and the rotating hopper is arranged on the weighing mechanism 4. The weighing mechanism is a mechanical weighing mechanism, and the mechanical weighing mechanism is equipped with a weight sensor. On the lever of the mechanical weighing mechanism, the weight sensor is connected to the control device. The control device is connected with the main motor, the rotating hoppe...

Embodiment 2

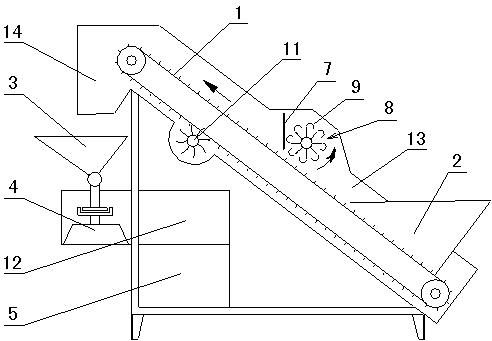

[0028] The feeding device of embodiment 2 is a feeding claw (see image 3 ), the claw is hook-shaped, and the direction of the hook tip is opposite to the direction of rotation of the claw. The weighing mechanism is an electronic weighing mechanism, the electronic weighing mechanism is provided with a weight sensor, and the weight sensor is connected to the control device, and the rest are the same as in Embodiment 1.

[0029] When the quantitative timing automatic feeding conveyor is working, the conveyor belt transports the tea leaves in the fixed hopper to the discharge end at a higher position. It may fall into the rotating hopper at the same time, causing a large weighing error. The limit plate is used to limit the height of the tea leaves on the conveyor belt and limit the upward transfer of the tea leaves that are too high; The tea leaves are dialed back to prevent piles of tea leaves on the conveyor belt. The tea leaves fall from the discharge end of the conveyor bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com