Power supply system of sliding contact line of trench of tyre crane of container yard

A container yard and power supply system technology, which is applied in the field of power supply system of the tire crane trench trolley line in the container yard, can solve the problems of slow flipping, heavy weight, and large volume, and achieve low cost, high cost performance, economical and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

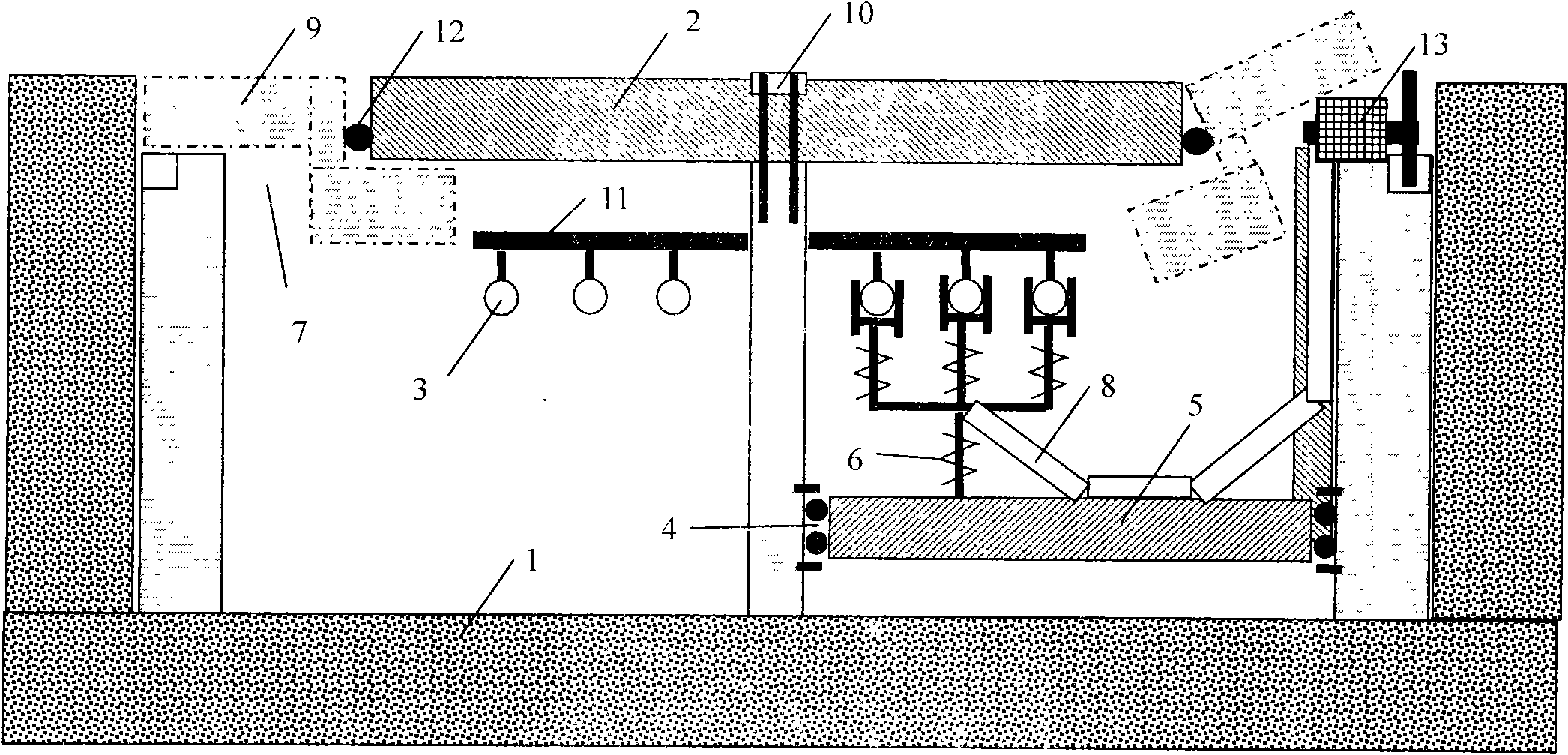

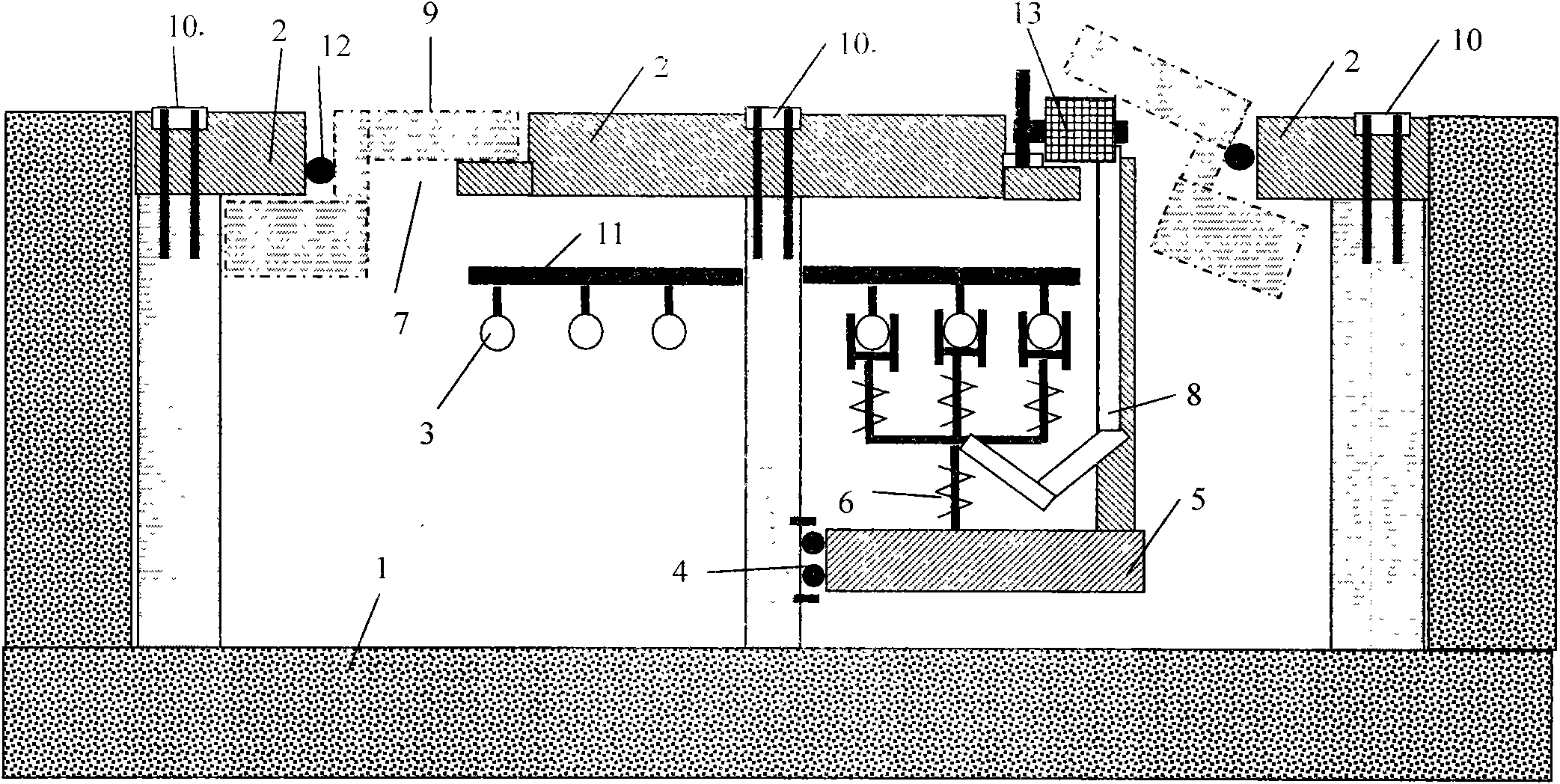

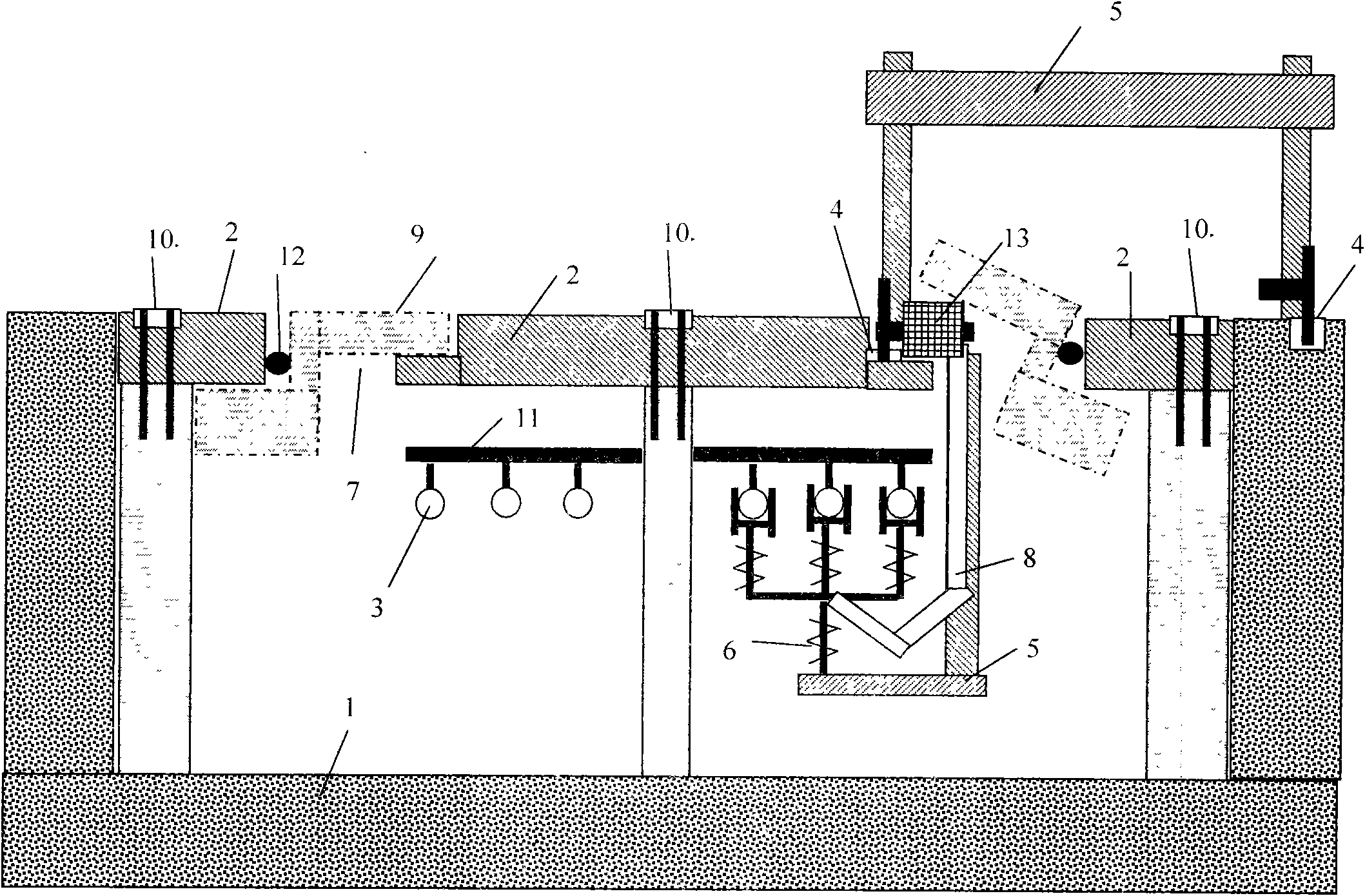

[0033] see figure 1 as shown, figure 1 Shown is the first specific embodiment of the power supply system for the trolley line of the tire crane in the container yard of the present invention, which includes a trench body 1 and a trench cover plate 2 covering the mouth of the trench body. In the body, a trolley line 3 is arranged along the extending direction of the tank body, and a track 4 is arranged parallel to the trolley line 3. A collector trolley 5 is movable on the track 4. The power-taking device of the trolley 5 is connected with the The trolley line 3 is in sliding elastic contact, and there is a gap 7 between the trench cover plate 2 and the trench body 1, and the gap 7 can also be as figure 2 and image 3 As shown in the second specific embodiment and the third specific embodiment, a traction conductive wire 8 is arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com