Three-way joint of fuel evaporation and emission control pipeline

An evaporative emission and pipeline control technology, applied in the direction of pipes/pipe joints/fittings, branch pipelines, pipes, etc., to achieve the effect of standard layout, cost reduction, and fewer pipe clamps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

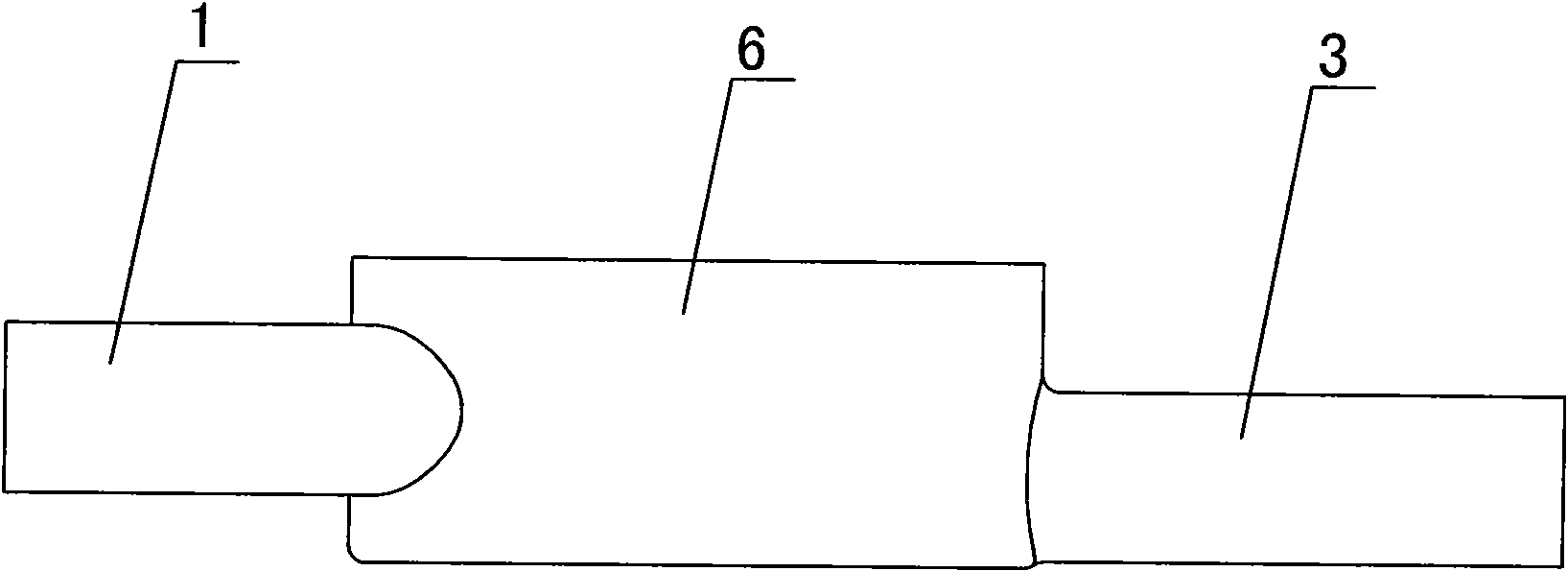

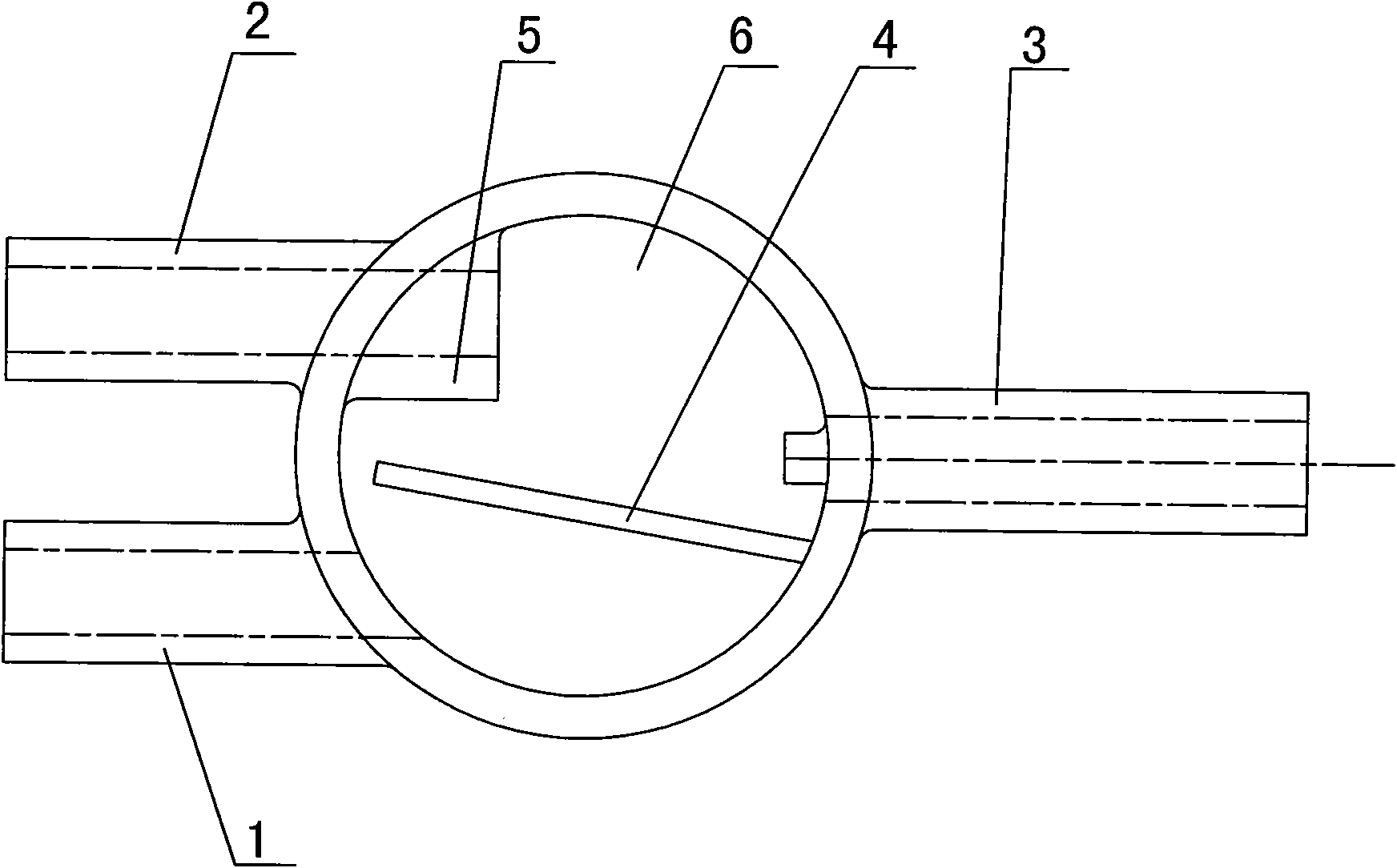

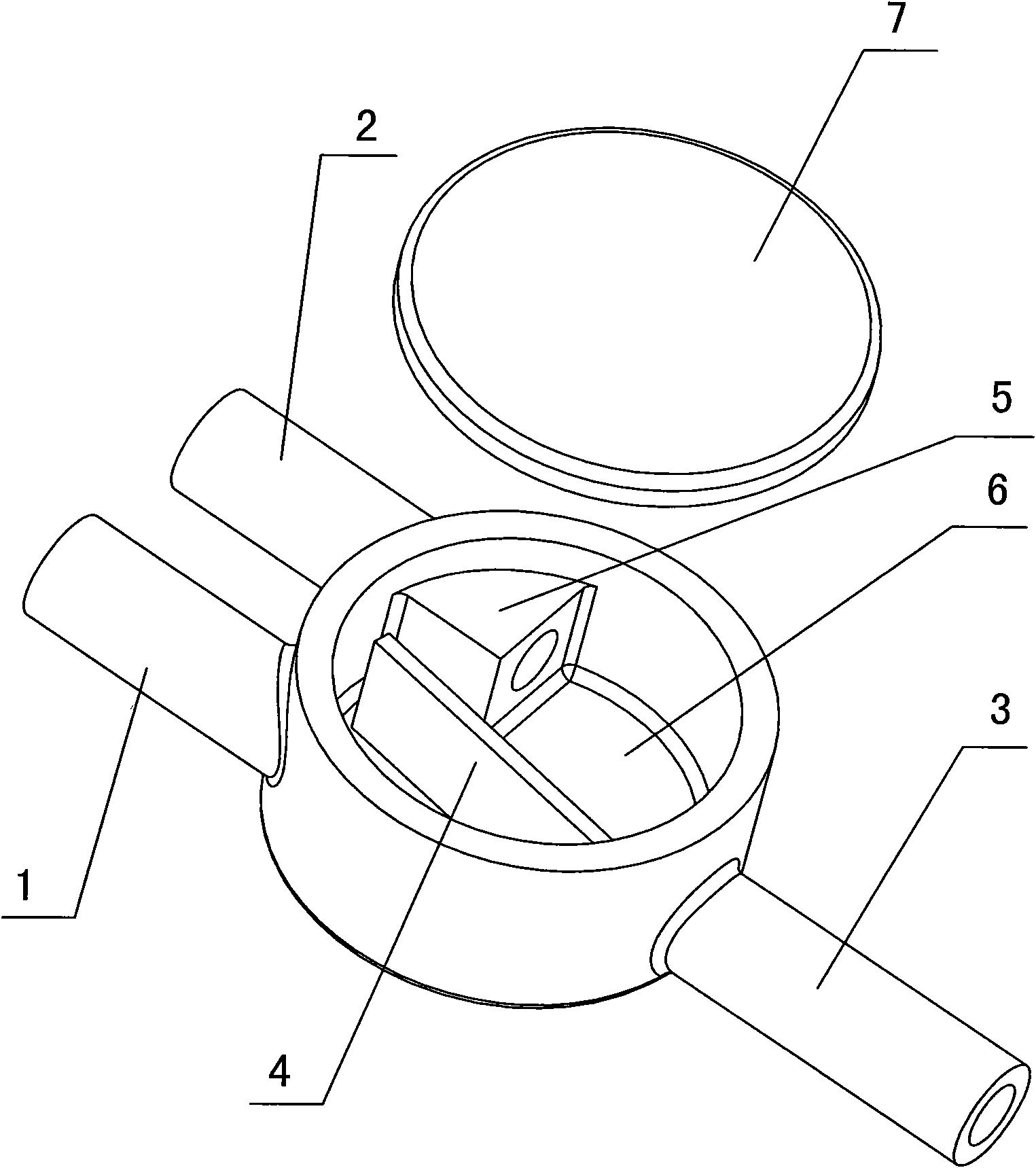

[0019] like Figure 1 to Figure 4 As shown, the tee joint of the fuel evaporative emission control pipeline has a first branch pipe 1, a second branch pipe 2 and a third branch pipe 3 that communicate with each other, and the orientation of the first branch pipe 1, the second branch pipe 2 and the third branch pipe 3 are opposite , the three branch pipes meet in the cylindrical cavity 6, and a baffle plate 4 is arranged in the cylindrical cavity 6. The baffle plate 4 makes the gap between the first branch pipe 1 and the second branch pipe 2, and between the first branch pipe 1 and the third branch pipe 3 To achieve a circuitous connection between. When in use, the first branch pipe 1 is used to connect the one-way air valve, the second branch pipe 2 is connected with the fuel tank, the third branch pipe 3 is connected with the carbon canister, and the baffle plate 4 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com