Complex pipeline moving rat

A technology in complex pipes and pipe walls, applied in the field of moving devices in pipes, can solve the problems of climbing vertical pipes and the inability of moving devices to pass effectively, and achieve the effects of enhanced adaptability, easy operation and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

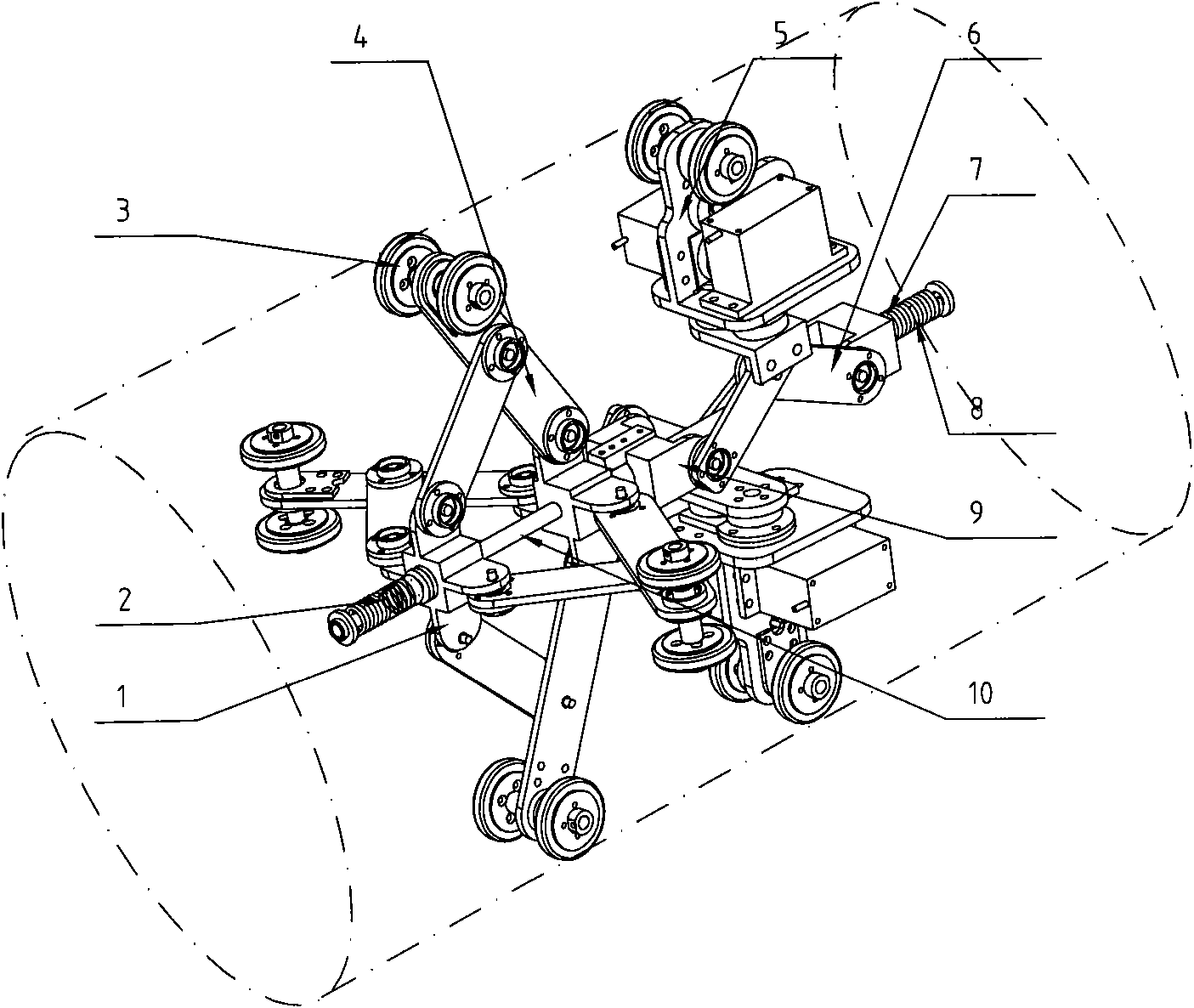

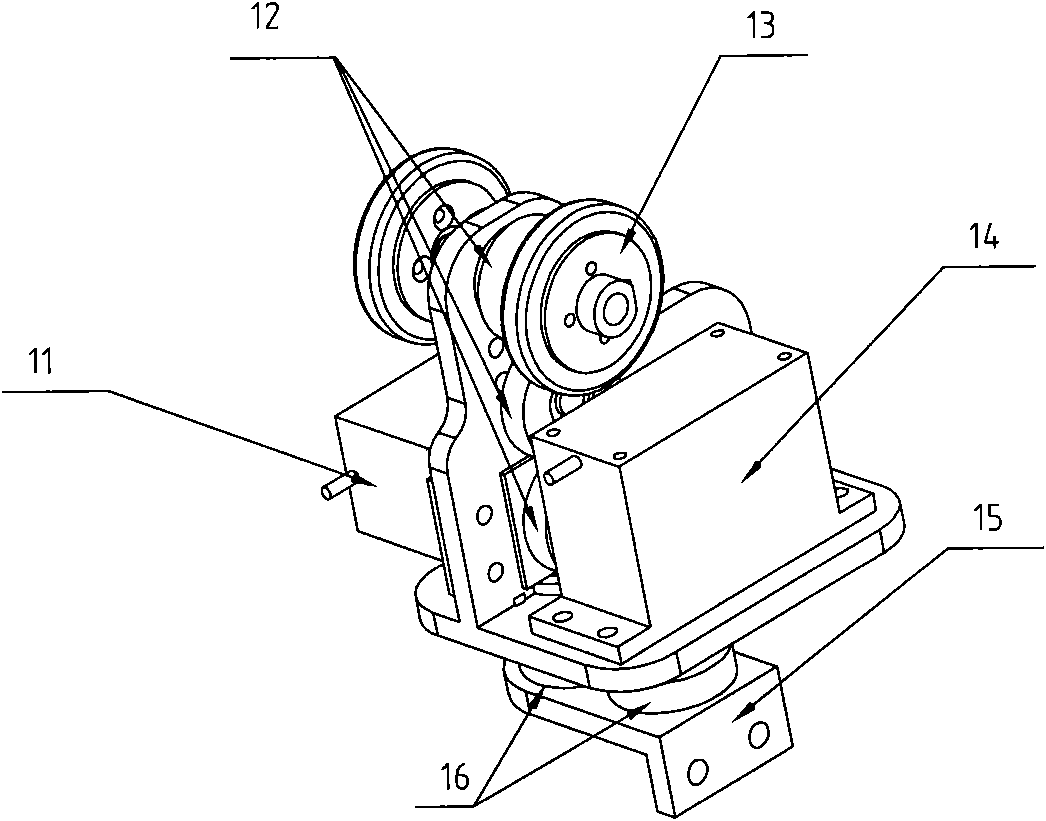

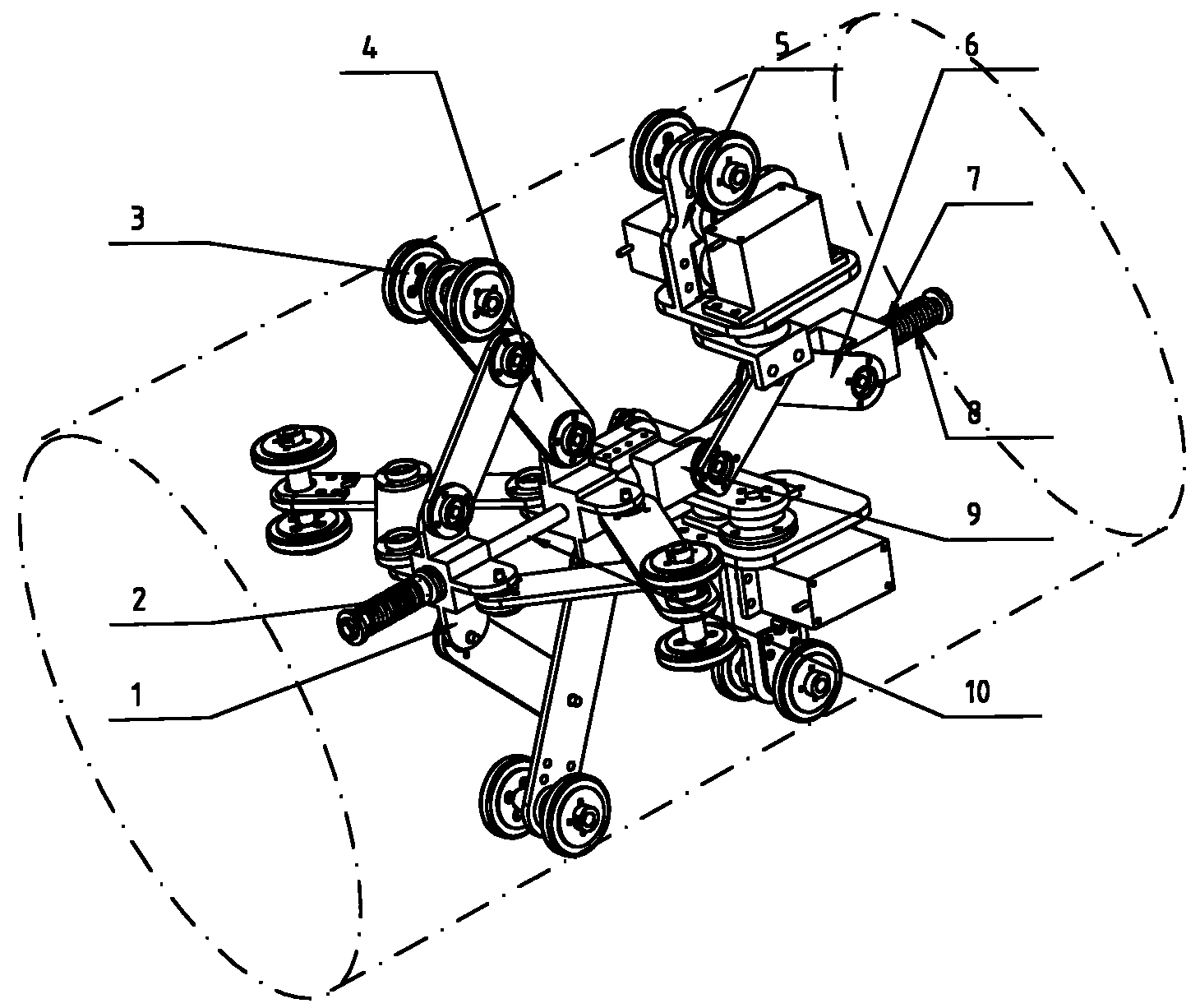

[0011] according to Figure 1~2 The specific structure of the present invention will be described in detail. The complex piping system drilling rat includes a cage and a driving body assembled on the same main shaft 10 assembled in the pipe wall (shown by the dotted line in the figure). The middle part of the main shaft 10 is fixed with a connecting seat 9 , and the two ends of the main shaft 10 are respectively movably assembled with a cage slider 1 and a driving body slider 7 . The cage includes a spring 2, a cage slider 1 movably assembled on the main shaft 10 by using the spring 2, a four-bar mechanism 4 hinged between the connecting seat 9 of the main shaft 10 and the cage slider 1, assembled on the four-bar mechanism 4 The support wheel 3 etc. parts of outer end. The support wheel 3 is tensioned in the pipe wall by adjusting the spring 2 at the end of the main shaft 10 . The driving body includes a spring 8, a driving body slider 7 that is movably assembled on the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com