Heat sink and LED light using same

A technology of LED lamps and heat sinks, which is applied to the cooling/heating devices, lighting devices, lighting and heating equipment of lighting devices, etc., can solve the problems of affecting the service life of LED lamps and unable to meet the demand for continuously increasing power of LED lamps, etc. Achieve the effect of improving practicability, improving heat dissipation problems, and increasing heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

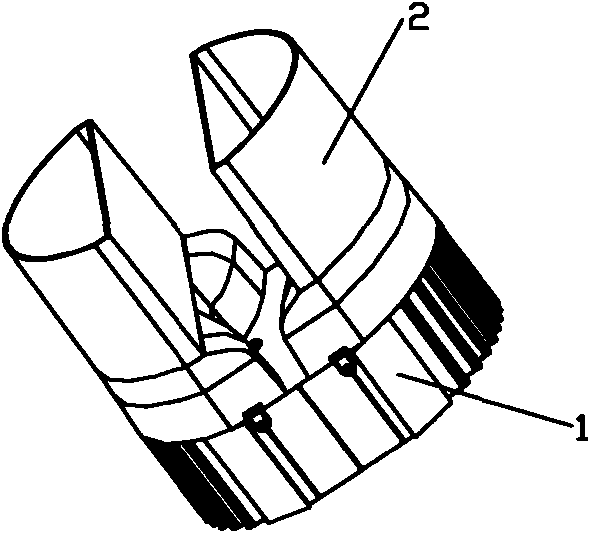

[0025] A cooling device, the structure of which is as follows figure 1 , including a radiator 1 and an air passage 2 installed on one side of the radiator 1 for air convection and heat dissipation.

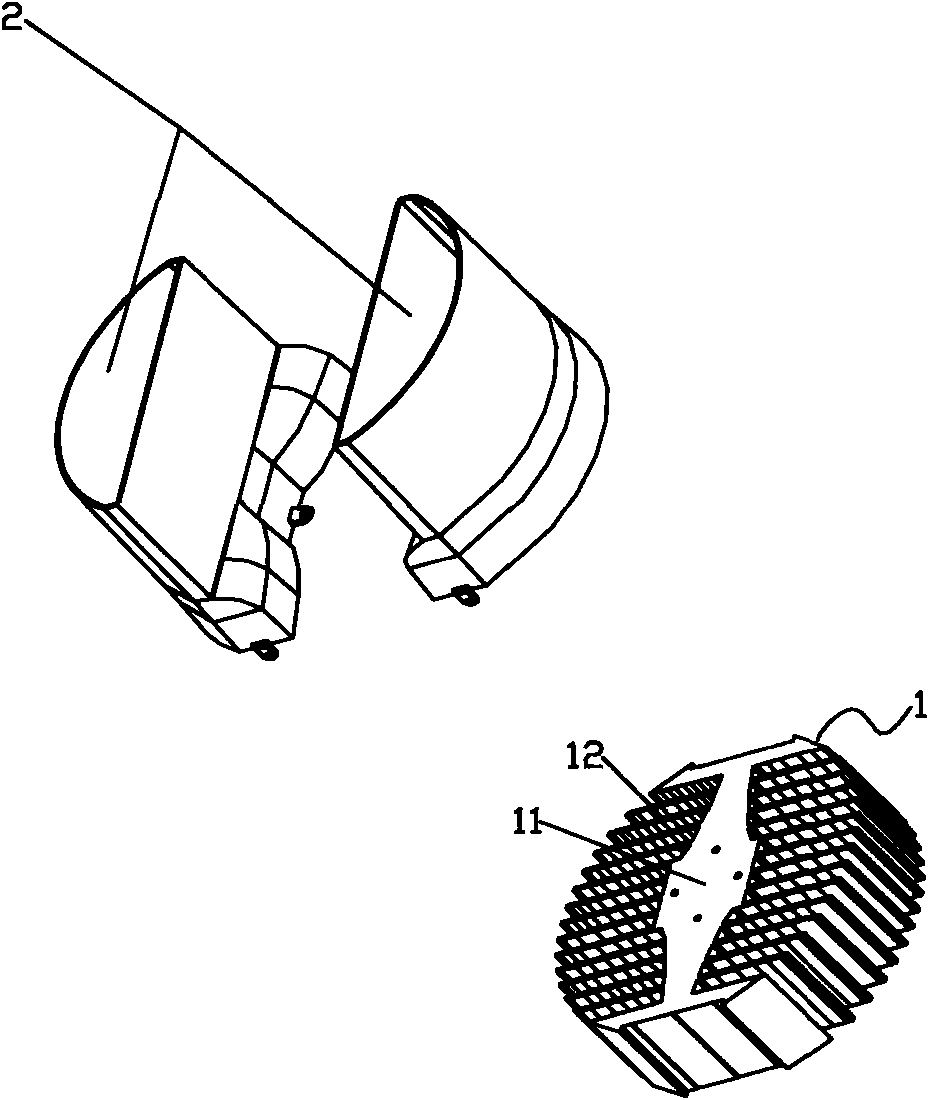

[0026] Radiator 1 is made of aluminum, and its structure is as follows: figure 2 As shown, it consists of a cylindrical heat dissipation base 11 and heat dissipation fins 12 arranged around the heat dissipation base 11 .

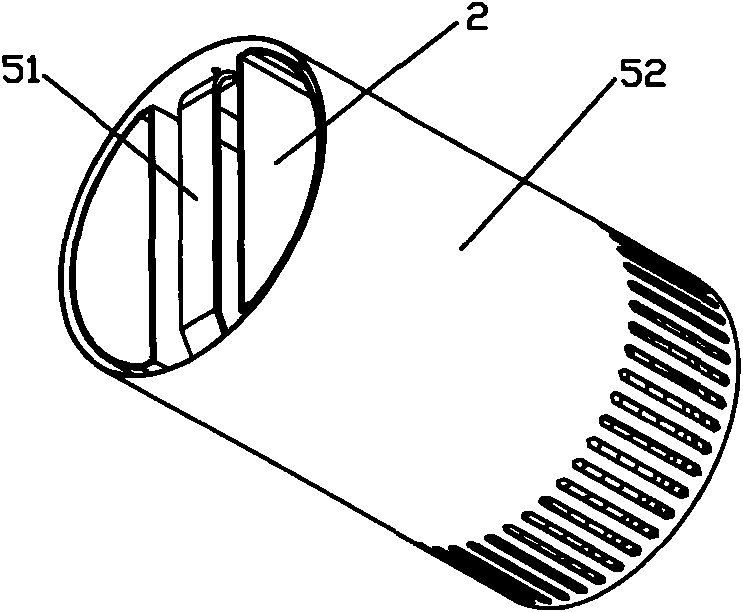

[0027] The air channel 2 is set in two, made of heat insulating material, and is a cylindrical structure with a central through hole, symmetrically fixedly connected to one side end surface of the radiator 1, and a gap gap. The through hole of the air channel 2 is perpendicular to the end surface of the radiator 1 .

Embodiment 2

[0029] An LED lamp is composed of three parts: the light source part, the cooling device and the power supply part. Its appearance assembly diagram is as follows: image 3 As shown, the internal structure is as Figure 4 , Figure 5 .

[0030] The heat sink adopts the heat sink described in Embodiment 1.

[0031] Light source parts such as Figure 5 , consists of a boss 31, an LED chip 32, a reflector 33, a silicone pad 34, a light-transmitting mirror 35 and a snap ring 36 in turn. The boss 31 is made of the same aluminum material as the heat sink 1 , and is embedded on the heat dissipation base 11 on one end surface of the heat sink 1 . The reflector 33 is mounted on the boss 31 , and an LED chip 32 is embedded at the bottom of the reflector 33 . The light-transmitting mirror 35 is fixedly mounted on the front end of the reflector 33 with a snap ring 36 , and a silicone gasket 34 is used for sealing between the reflector 33 and the light-transmitting mirror 35 .

[0032...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com