Fully enclosed liquid resistance starter

A technology of liquid resistance and starter, which is applied in the direction of motor generator/starter, single multi-phase induction motor starter, etc., which can solve the problems of decreased effective utilization rate, frequent equipment maintenance, inconvenient operation, etc., and prolongs the use time and service life, avoiding the effect of excessive evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

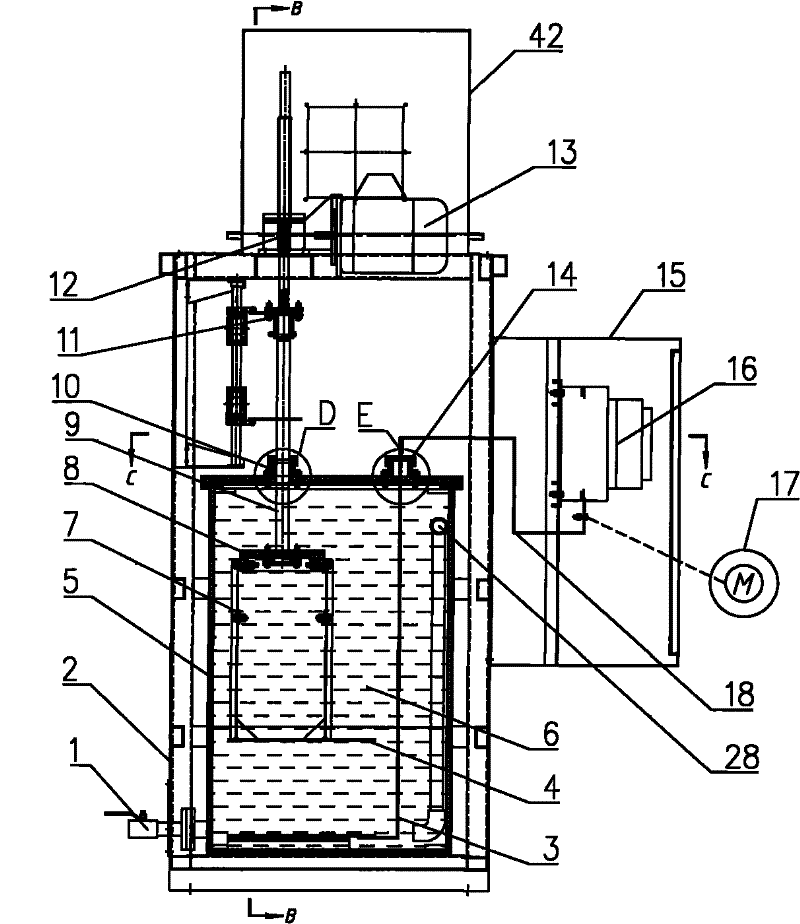

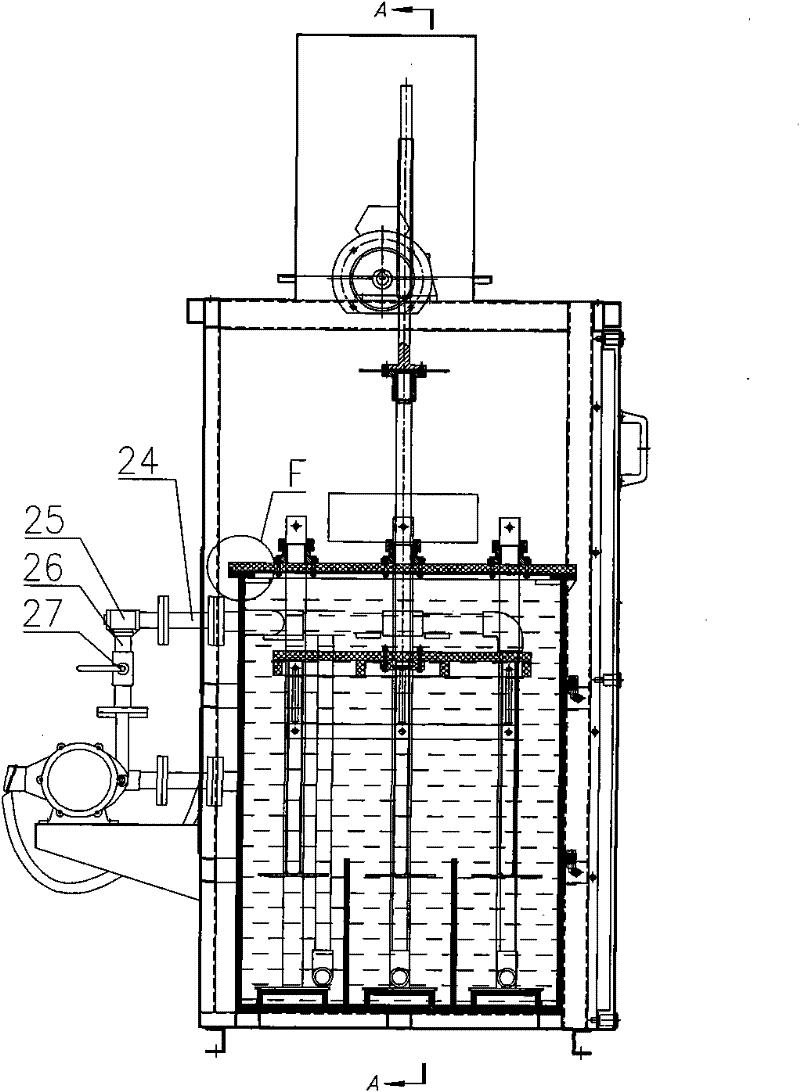

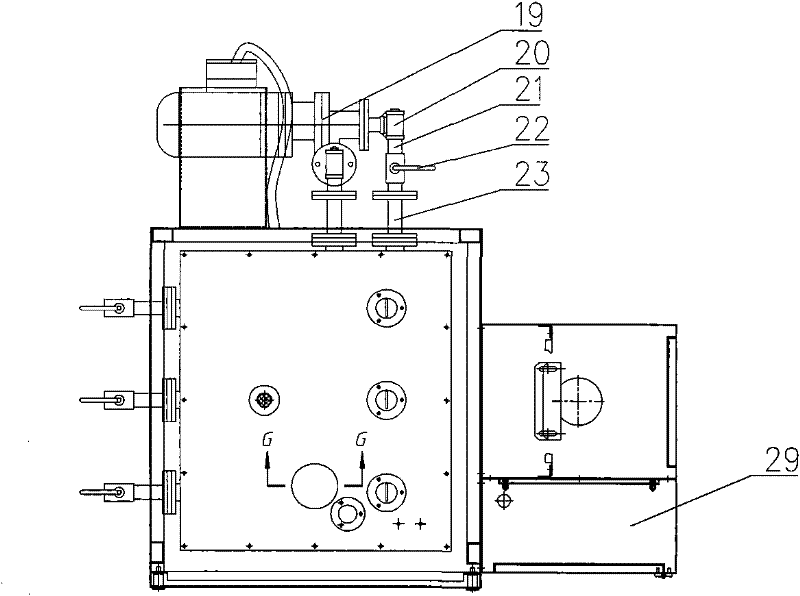

[0016] exist figure 1 , figure 2 , image 3 In the embodiment, adopt the electrolytic solution box body 5 that insulating material is made, be arranged in the liquid resistance starter box body 2, in the electrolytic solution box 5, be divided into three separate liquid tanks equally with insulating partition plate, fixed electrode 3, The movable electrode 4 and the lifting frame 8 are located in the electrolyte 6 in the electrolyte tank 5, and the lower ends of the movable electrode 4 and the fixed electrode 3 are respectively located in three separate tanks. The movable electrode 4 is suspended on the lifting frame 8 made of insulating material, and the lifting frame 8 is fixed on the insulating rod 9. After the insulating rod 9 passes through the first sealing assembly 10 on the electrolyte tank cover 32, connect the connecting sleeve 11 with the fitting The lower end of the screw on the worm lifter 12 is installed together, and the worm lifter 12 and the motor 13 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com