Elastic heat dissipating bracket for deep-sea seal cavity

A technology of sealing cavity and heat dissipation rack, which is applied in the direction of cooling/ventilation/heating transformation, etc., which can solve the problems of electric component amplitude effect, influence on reliability, and long heat conduction path, so as to avoid pressure rise, increase heat dissipation area, and expand The effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

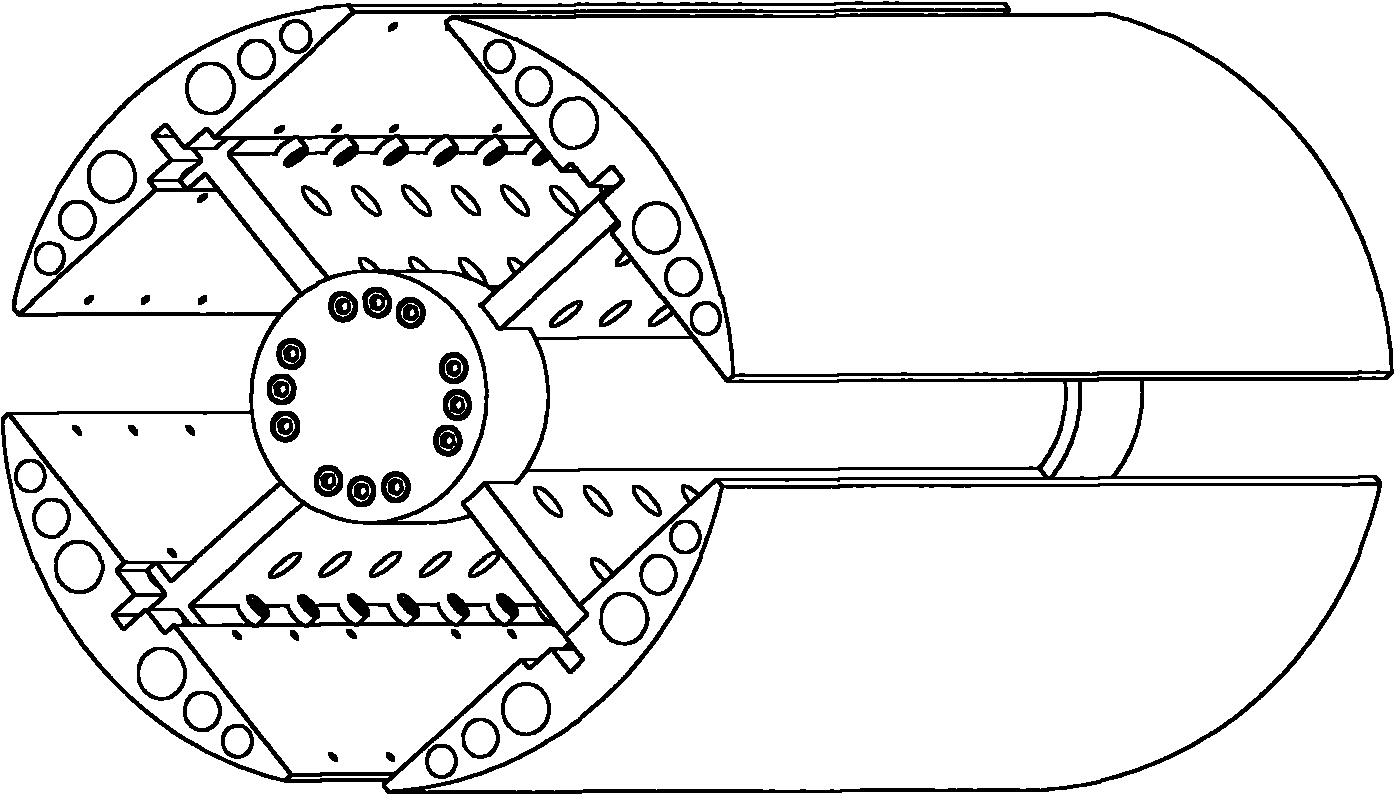

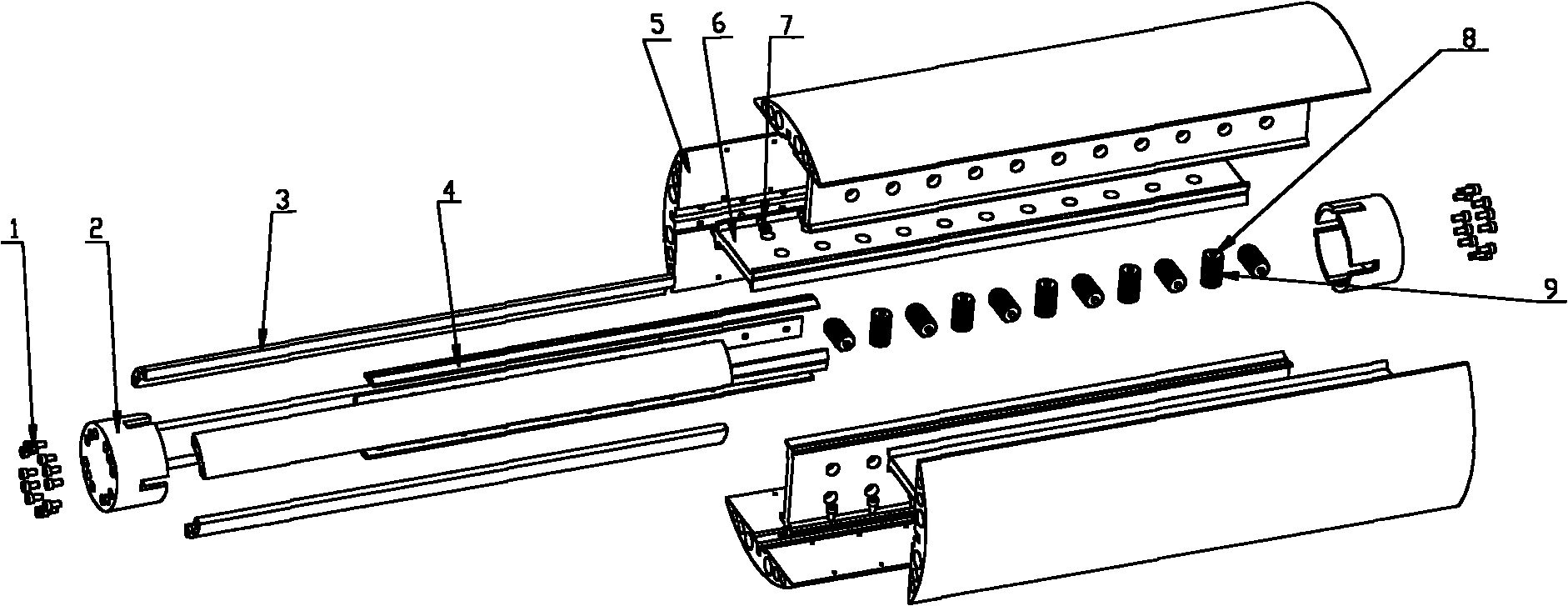

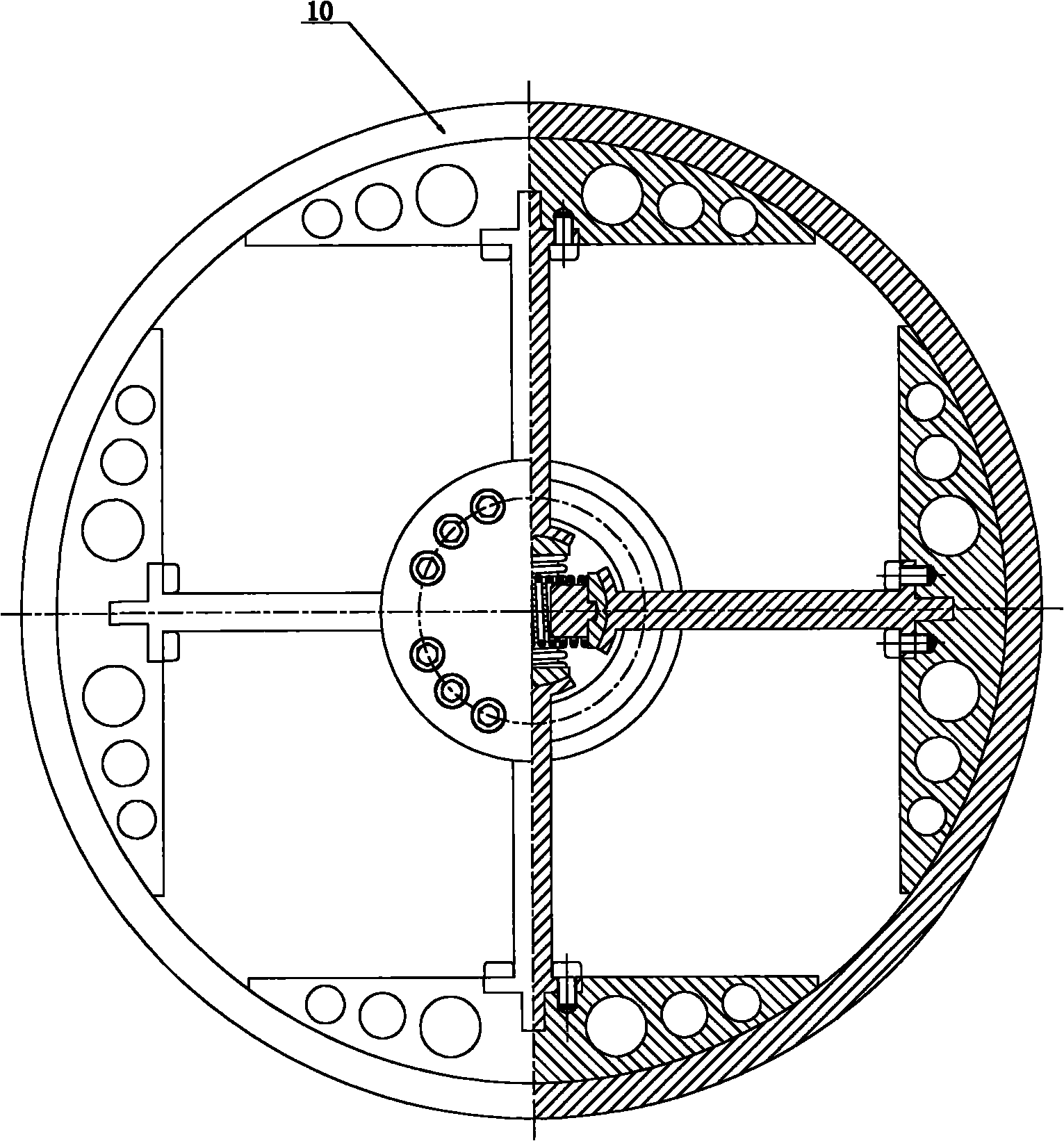

[0015] The elastic heat dissipation frame of the deep-sea sealed chamber of the present invention includes a heat dissipation plate, a heat dissipation plate support frame, a support frame fixing screw group, a support frame fixing plate, a spring seat bottom plate, a spring seat, a spring, a support frame fixing plate end cover, and an end cover fixing screw. The support frame of the heat sink is inserted into the groove in the middle of the heat sink and fixed on the heat sink by the support frame fixing screw group. The four support frame fixing plates are inserted into the circular grooves inside the end cover of the heat sink fixing block and fixed by the end cover Screws fix the end cover of the support frame fixing plate and the support frame fixing plate. The four cooling plate support frames can just be stuck in the four slots of the four support frame fixing plates. The spring seat is fixed on the bottom plate of the spring seat through the thread at the bottom. On a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com