Nozzle for high-shear homogenate pump

A high-shear, nozzle-based technology used in dissolution, mixers, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

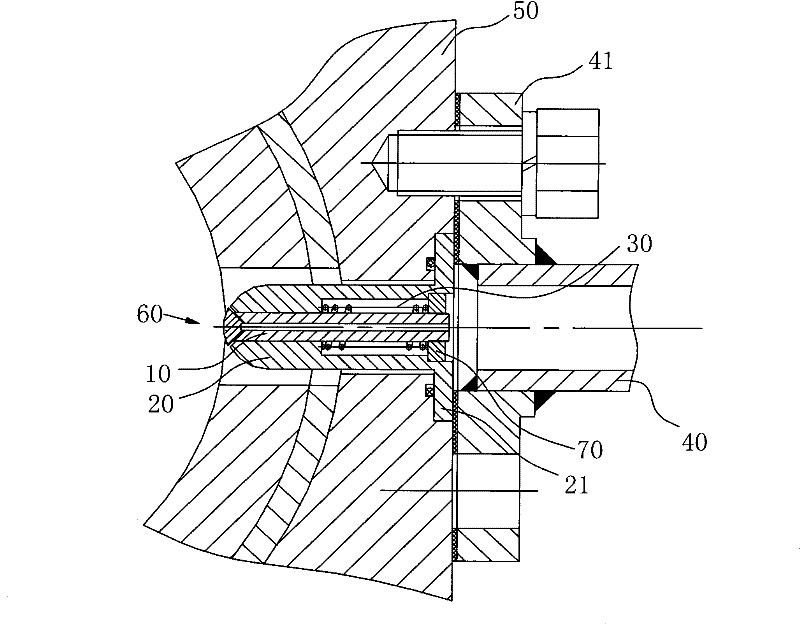

[0017] Such as figure 1 As shown, the high-shear homogenate pump is a top-in and top-out structure, the direction of the inlet and outlet is perpendicular to the axis, and the direction of rotation is clockwise when viewed from the direction of the driving end. The high-shear homogenate pump is equipped with an auxiliary material adding pipe 40 according to the process requirements, and the matting agent in the matting raw liquid homogenate pump is added from this port. Special nozzles, the installation method see figure 1 . It is fixed on the inner wall of the pump body 50 and installed along the radial direction. The TiO2 water distribution pipeline is injected into the raw liquid in the pump cavity through the auxiliary material adding pipe 40. In order to prevent the backflow of the raw liquid from causing gelation, the present invention designs a nozzle with a non-return sealing structure.

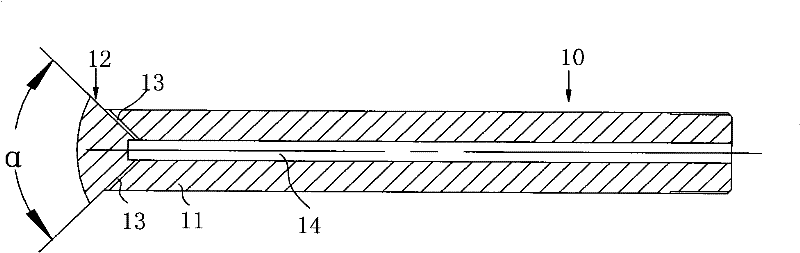

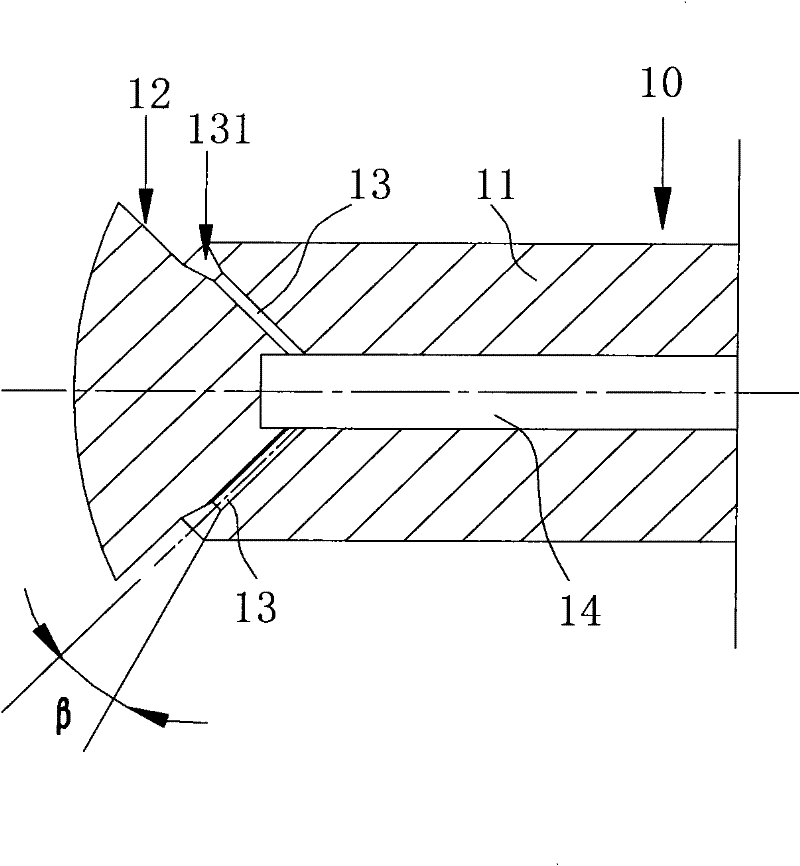

[0018] Such as figure 2 As shown, the auxiliary material feeding port uses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com