Delivery pipe cleaning device

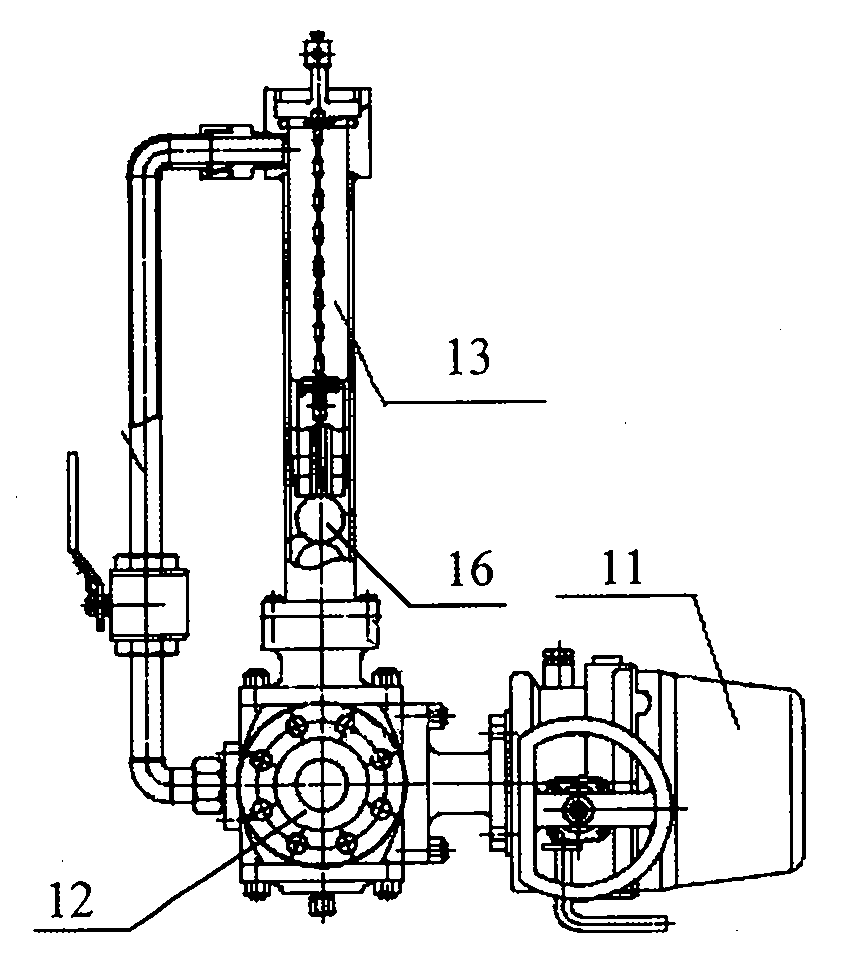

A technology of pigging and pigging balls, applied in the field of oil transportation, can solve the problems of crude oil leakage, 11 large motors, hidden safety hazards, etc., and achieve the effect of simple maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

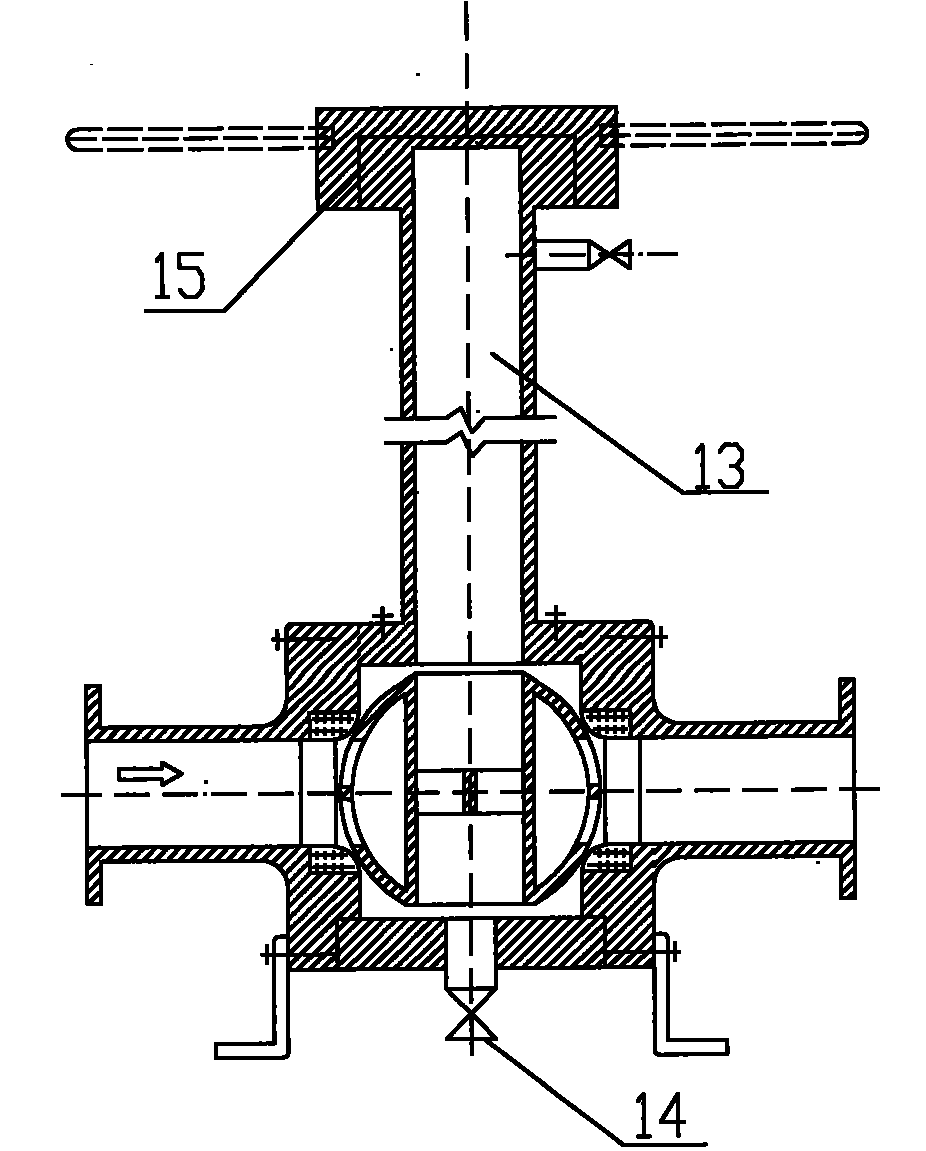

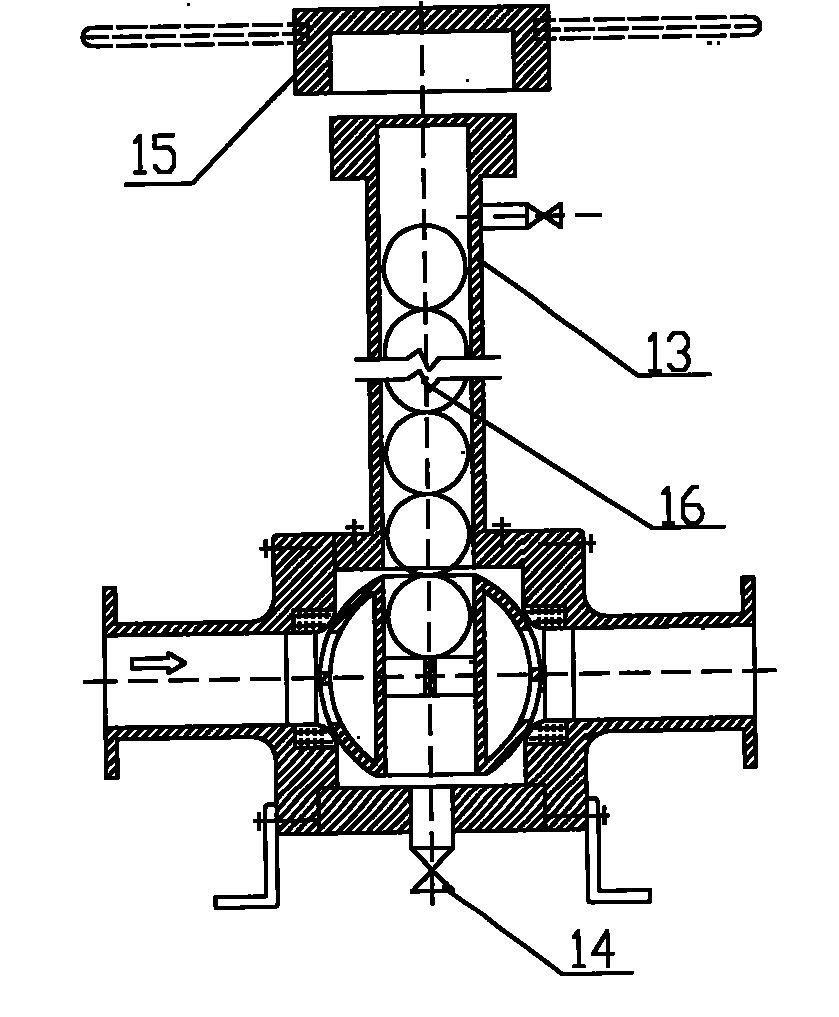

[0030] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] see Figure 5 , is a schematic diagram of the ball-pigging pigging device of the present invention, the upper end of the ball storage cylinder 22 is communicated with the oil inlet pipeline 21, and the lower end is communicated with the oil outlet pipeline 23, crude oil enters the ball storage cylinder 22 from the oil inlet pipeline 21, and is output from the oil outlet pipeline 23, In this way, the storage ball tube 22 itself is a part of the oil delivery pipeline. This scheme combines the storage ball pipeline 22 and the oil delivery pipeline into one, with an integrated design, warm crude oil will flow through the storage ball pipeline 22 continuously, avoiding the problems of wax deposition and blockage caused by the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com