Method for producing sodium chromate from potassium chromate

A technology for the production of sodium chromate and potassium chromate, applied in the direction of chromate/dichromate, etc., can solve the problems of polluted water body, soil and atmosphere, backward technology, and resource utilization rate of less than 20%, and it is easy to achieve engineering scale-up , simple equipment requirements and mild conversion conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

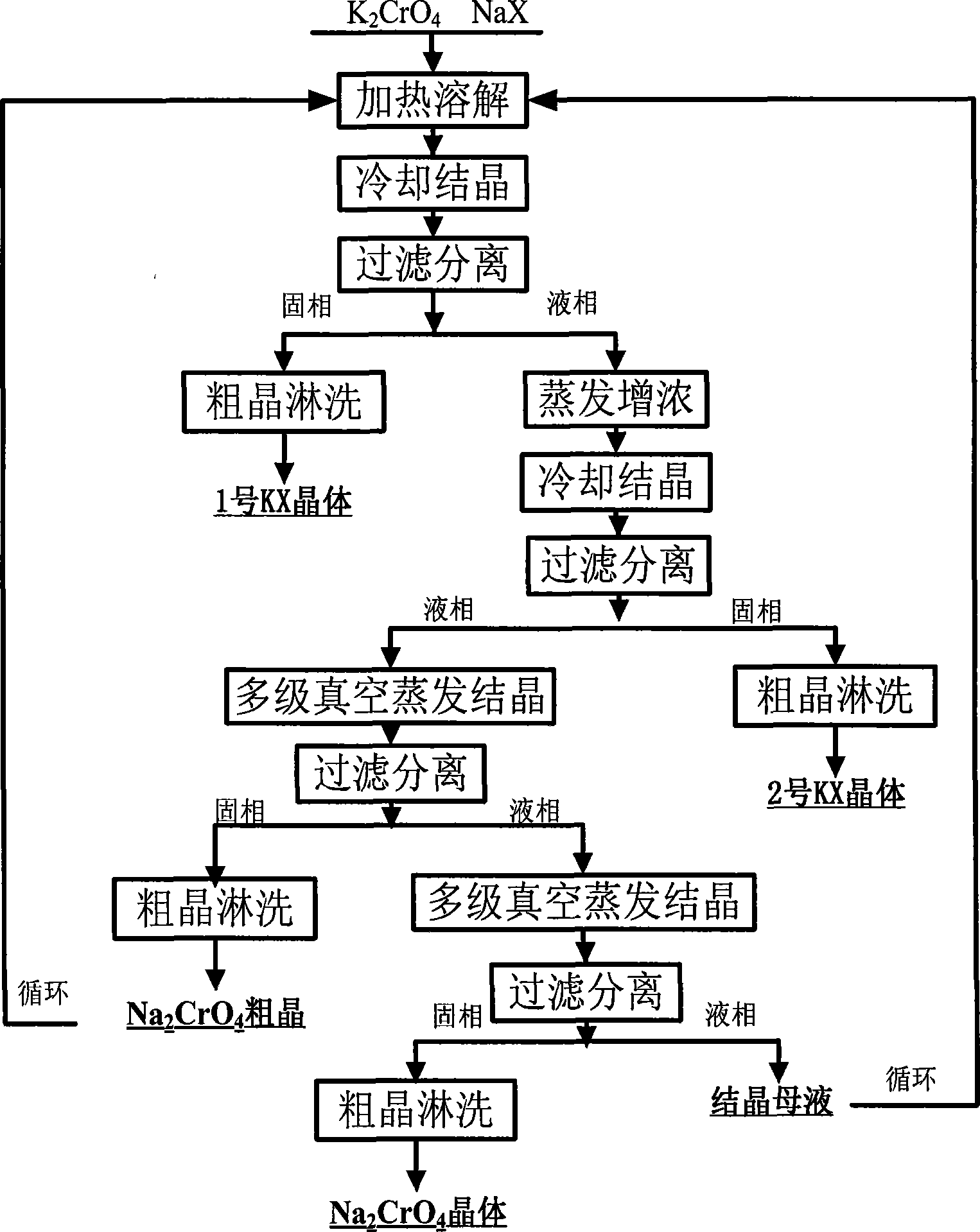

Method used

Image

Examples

Embodiment 1

[0020] Mix potassium chromate crystals and sodium nitrate crystals in a mass ratio of 2:1 to prepare an aqueous solution, raise the temperature to 90°C, and stir at a speed of 150min -1 After 30 minutes of complete dissolution and stability, the temperature began to drop, and the temperature was kept at a constant temperature for 30 minutes after dropping to 20°C. The liquid and solid phases were separated, and the coarse crystals of potassium nitrate were separated. Evaporate and concentrate the resulting crystallization mother liquor, repeat the cooling and crystallization process, raise the temperature to 90°C, and stir at a speed of 150min -1 , after lowering to 20°C, keep the constant temperature for 30min, vacuum filtration to separate the solid and liquid phases, and conduct multi-step vacuum evaporation and crystallization of the obtained crystallization mother liquor at 90°C to obtain Na 2 CrO 4 crystals.

Embodiment 2

[0022] Mix potassium chromate crystals and sodium nitrate crystals in a mass ratio of 1:1 to prepare an aqueous solution, raise the temperature to 70°C, and stir at a speed of 150min -1 After 30 minutes of complete dissolution and stability, the temperature began to drop, and the temperature was kept at a constant temperature for 30 minutes after dropping to 20°C. The liquid and solid phases were separated, and the coarse crystals of potassium nitrate were separated. Evaporate and concentrate the resulting crystallization mother liquor, repeat the cooling and crystallization process, raise the temperature to 70°C, and stir at a speed of 150min -1 After dropping to 20°C, the constant temperature was maintained for 30 minutes, and the solid-liquid two phases were separated by vacuum filtration, and the obtained crystallization mother liquor was subjected to multi-step vacuum evaporation and crystallization at 80°C to obtain Na 2 CrO 4 crystals.

Embodiment 3

[0024] Mix potassium chromate crystals and sodium sulfate crystals in a mass ratio of 1:2 to prepare an aqueous solution, raise the temperature to 60°C, and stir at a speed of 350min -1 After 60 minutes of complete dissolution and stability, the temperature began to drop, and the temperature was kept at a constant temperature for 60 minutes after dropping to 0°C. The liquid and solid phases were separated, and the coarse crystals of potassium sulfate were separated. Evaporate and concentrate the obtained crystallization mother liquor, repeat the cooling and crystallization process, raise the temperature to 60°C, and stir at a speed of 350min -1 , keep the constant temperature for 60 minutes after dropping to 0°C, vacuum filtration to separate the solid-liquid two phases, and the obtained crystallization mother liquor is subjected to multi-step vacuum evaporation and crystallization at 75°C to obtain Na 2 CrO 4 crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com