Preparation method of triketone dehydrogenation product

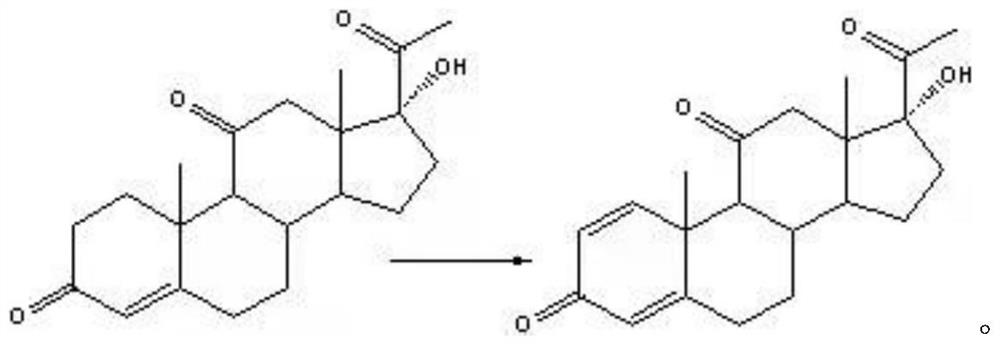

A triketone and dehydrogenation technology, applied in the field of preparation of triketone dehydrogenates, can solve the problems of poor substrate solubility, low conversion rate, long conversion period and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Simply Pylori Seed Culture

[0028] Slap medium: 2% glucose, 2% yeast paste 2%, pH 7.5, agar 2%, 20 min sterilized for 30 min, and inoculate simple node bacteria (ARTHROBACTER SIMPLEX CPCC 140451). Culture Conditions: 25-32 ° C, 1-6 days.

[0029] The first-class seed medium: 2% glucose, 2%, protein 胨 1%, yeast paste 0.5%, potassium phosphate 0.5%, pH 7.0-8.0.121 ° C, sterilization for 30 min. Simply node bacillus under the sterile conditions, culture conditions: 500 ml shake bottled 100ml seed medium, 30-32 ° C, speed of 200 rpm, and culture time 48 h.

[0030] Secondary seed medium: 2% glucose, 2%, protein 胨 1%, yeast paste 0.5%, 5% phosphoric acid dihydrogen, pH 7.0-8.0.121 ° C, sterilized for 30 min. Under aseptic conditions, a seed seed was allowed to inoculate 20%, cultural conditions: 500 ml shake bottled 100ml seed medium, 30 ° C, speed of 200 rpm, and culture time 48 h.

[0031] Fermented tank seed medium: 2% glucose, 2%, protein 胨 1%, yeast paste 0.5%, 0...

Embodiment 2

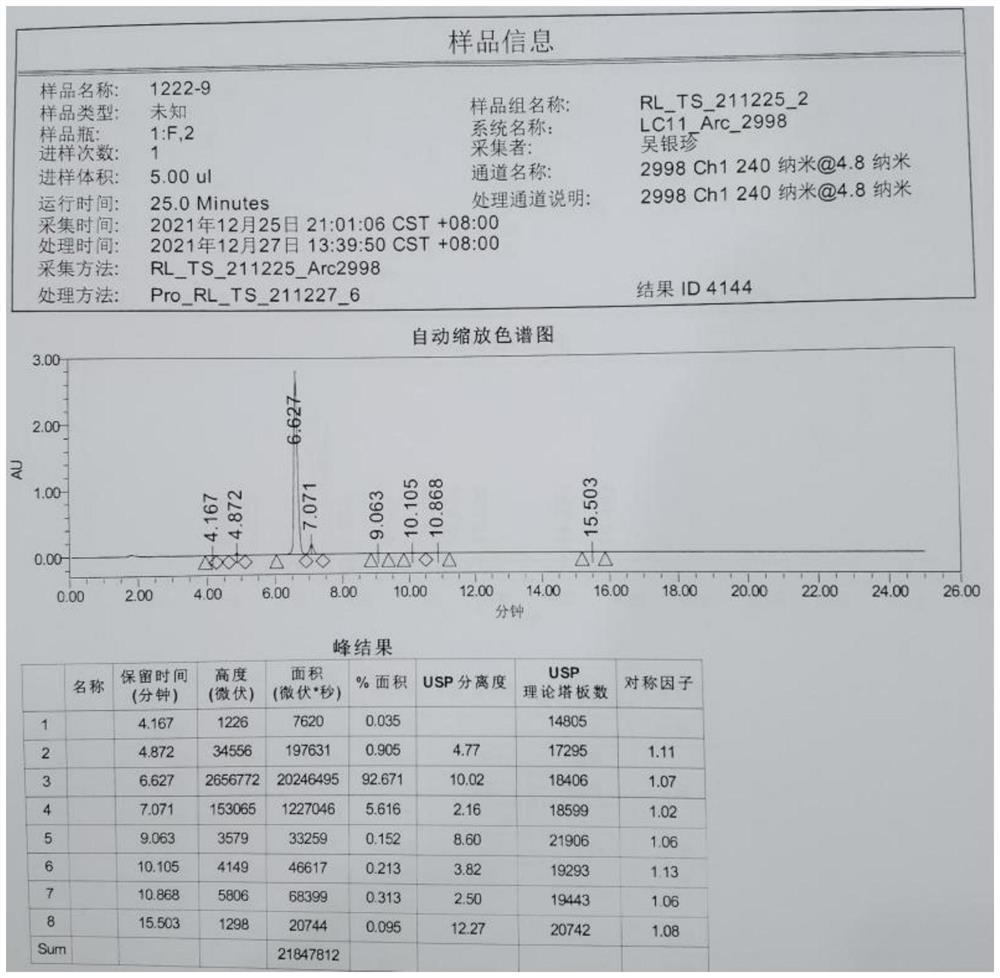

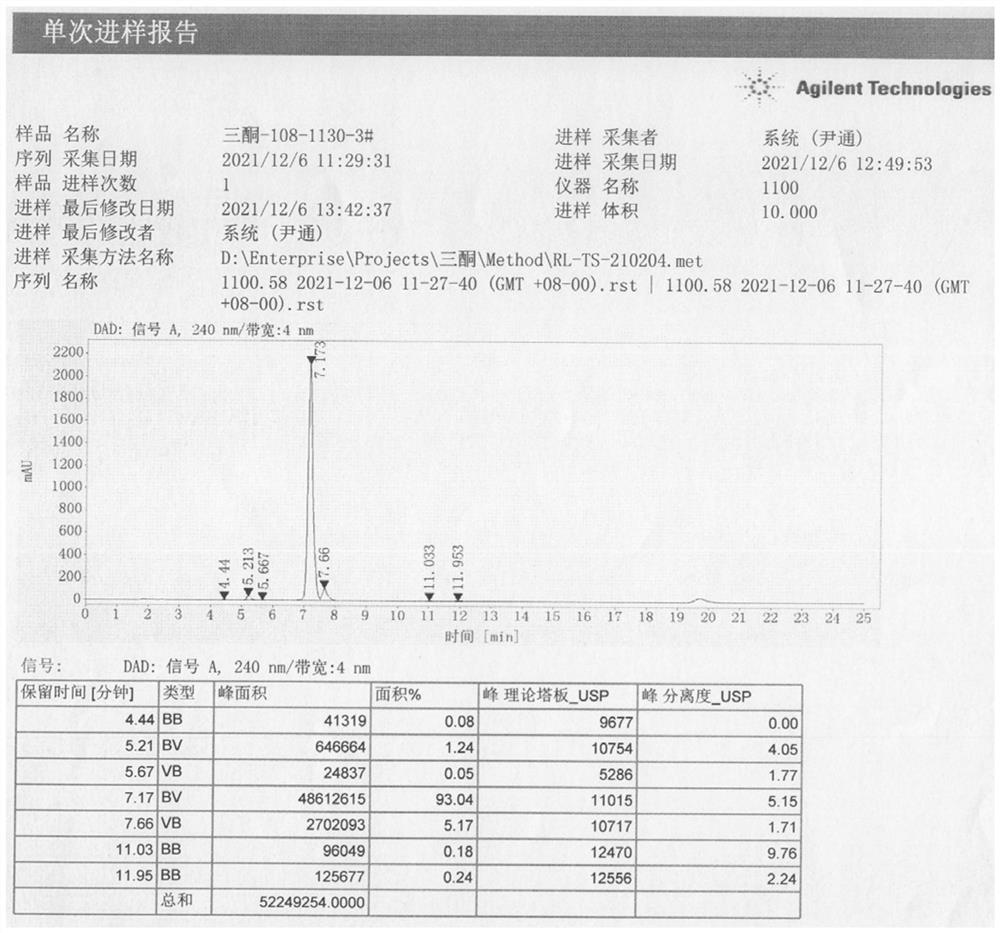

[0059] According to Example 1, a shake bottle seed culture was carried out, and the primary seed liquid was allowed to enter 100 mL of secondary seed medium for secondary seed culture. After 48 h, 3 g of triketone was added to the cultured secondary seed, 0.05 g Tween-80, 0.5 g Polyether Following agent PPE, 0.5GPMS, conversion conditions: 30 ° C, 200 rpm, conversion time 64 h, after conversion, the translation of HPLC, triketone dehydrate conversion of 88.39%, trinone transformation 9.22%.

Embodiment 3

[0061] According to Example 1, a shake bottle seed culture was carried out, and the primary seed liquid was allowed to enter 100 mL of secondary seed medium for secondary seed culture. After 48 h, 3 g of triketone was added to the cultured secondary seed, 0.05 g Tween-80, 0.5GPMS, 1G polyether ablying agent PPE, conversion conditions: 30 ° C, 200 rpm, conversion time 64h, after conversion, the translation of HPLC, triketone dehydrate conversion is 89.70%, triketone conversion 7.965%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com