Glass tempering air-cooling device

An air-cooling device and glass fiber reinforced plastic technology, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of inability to adjust the curved surface of the bellows, high manufacturing cost, and high use cost, and achieves good blowing effect and long service life. , the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

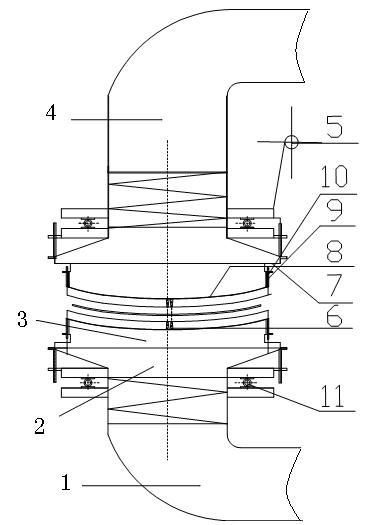

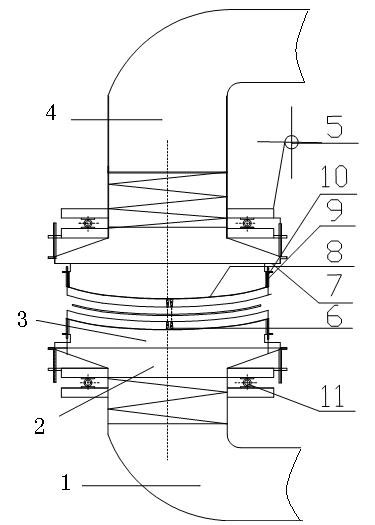

[0012] As shown in the figure, a FRP air-cooled device includes a lower air duct 1, a lower air box 2, an upper air box 3, an upper air duct 4, a lower air box, an upper air box lifting device 5, a lower air duct 1, an upper air duct 4, a lower air box, and an upper air duct. The bellows lifting device 5 is the same as the prior art, so it will not be described in detail here. The feature of the present invention is that the opposite sides of the lower bellows 2 and the upper bellows 3 are respectively provided with connection holes connected with the upper air duct 4 and the lower air duct 1, and the lower bellows 2 and the lower air duct The corresponding surface of the upper bellows 3 is the air outlet surface, and at least 100 air outlets are arrayed on the air outlet surface, and the air outlets are respectively provided with blowing nozzles 6 made of rubber materials. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com