Tempering device for improving surface strength of titanium alloy

A surface strength and tempering device technology, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems affecting tempering processing, the difference in the heating of the bottom surface of the parts, etc., to enhance the balance, reduce the tempering cost, Avoids the effect of improving unevenness in surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

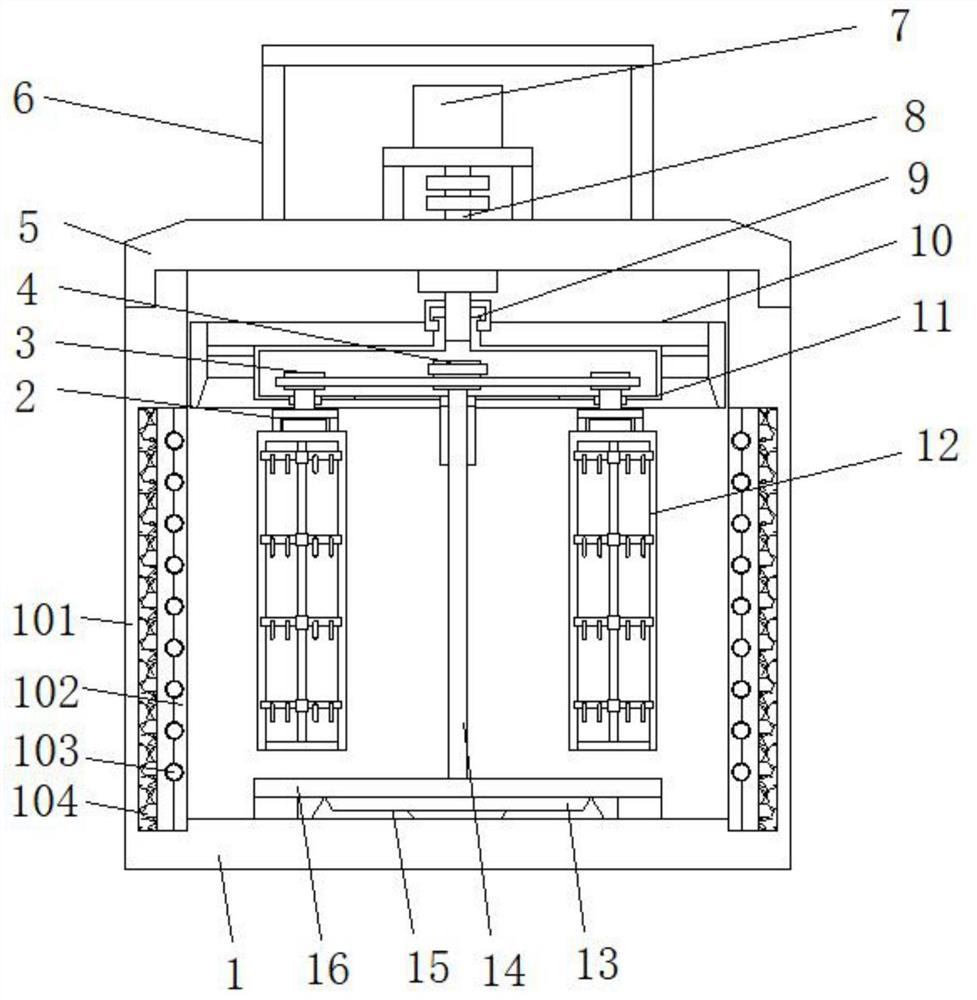

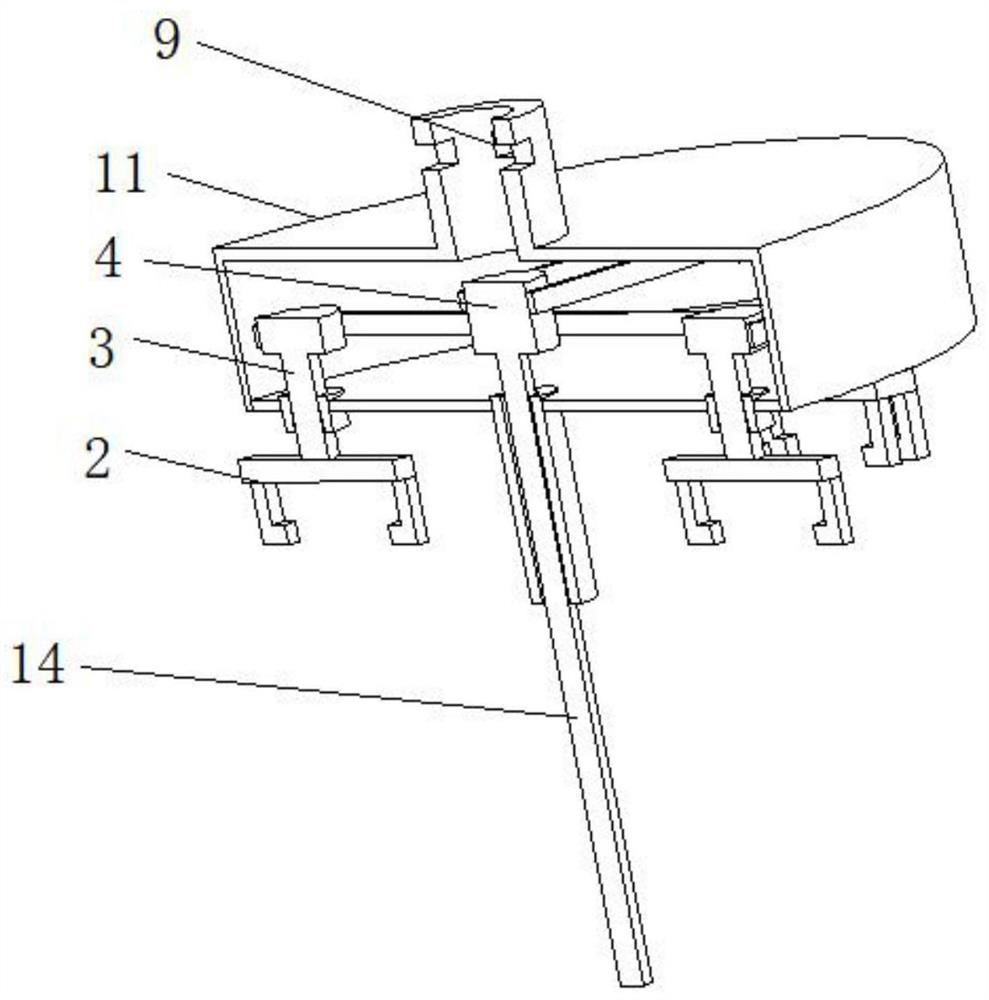

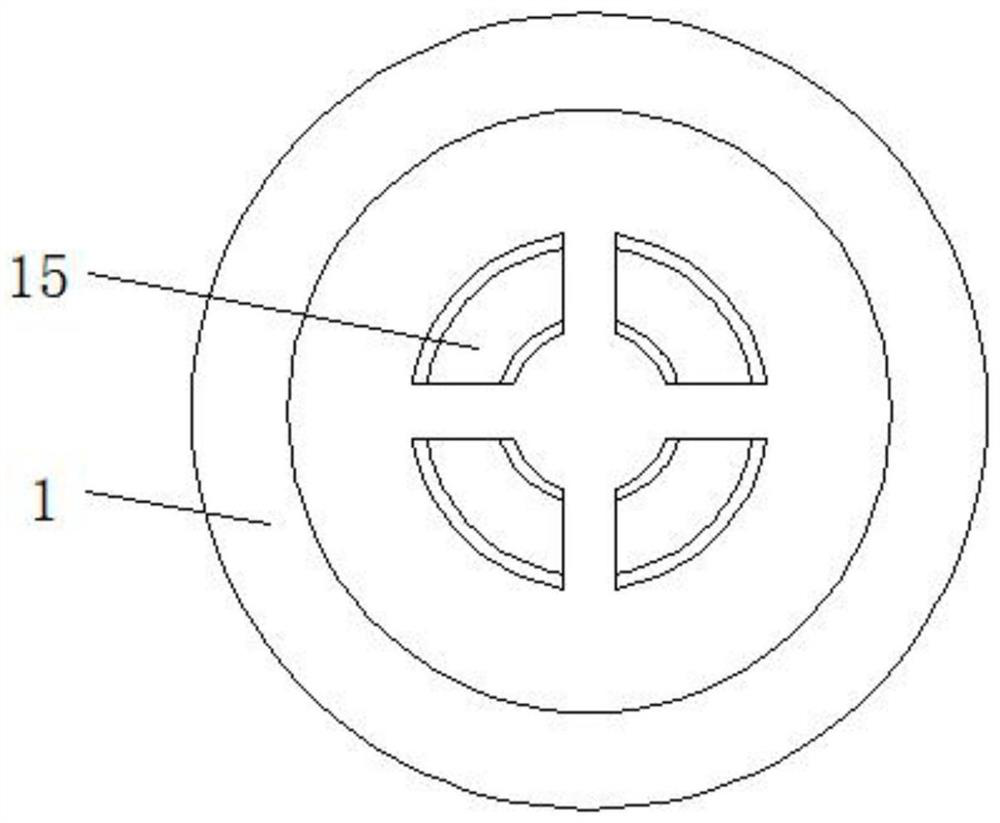

[0028] refer to Figure 1-5 , a tempering device for improving the surface strength of titanium alloys, comprising a furnace body 1, a furnace cover 5 is fixedly installed on the top of the furnace body 1, and a hanger 6 is fixedly installed on the top of the furnace cover 5, and the top of the furnace cover 5 is mechanically The seal is rotatably mounted with a suspension rod 8, and the top end of the furnace cover 5 is fixedly mounted with a drive motor 7 connected to the suspension rod 8. The inside of the furnace body 1 is provided with a housing 11, and between the housing 11 and the suspension rod 8 A connecting mechanism 9 for easy disassembly and assembly is provided, and a plurality of connecting rods 3 are mounted on the inner bottom of the housing 11 for rotation, and the bottom of the connecting rods 3 is fixedly mounted with a clamping hook 2, and the bottom of the clamping hook 2 is fixedly mounted with a hanging hook. Frame mechanism 12, the bottom end of housin...

Embodiment 2

[0039] refer to Figure 1-5 , a tempering device for improving the surface strength of titanium alloy. Compared with Embodiment 1, in this embodiment, a reflector 10 is fixedly installed on the outside of the housing 11, and the outside of the reflector 10 is adapted to the inner wall of the furnace body 1. , The outer side of the reflection cover 10 is provided with a heat insulating layer.

[0040] When this embodiment is in use, when the device is performing annealing operations, the reflector 10 provided at the bottom of the furnace cover 5 rotates with the casing 11, and then the heat is reflected by the reflector 10, and the heat is collected to improve the heating of titanium alloy parts. The uniformity of titanium alloy parts further improves the surface strength improvement effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com