Caterpillar transmission chain link full-automatic tempering processing device and operation method thereof

A technology of crawler transmission and processing equipment, applied in heat treatment equipment, manufacturing tools, furnaces, etc., can solve the problems of poor tempering treatment quality of chain rail links, uneven heat distribution, and the need to distinguish left and right chain rail links, etc., to improve Tempering quality, improved heat uniformity, effect of improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

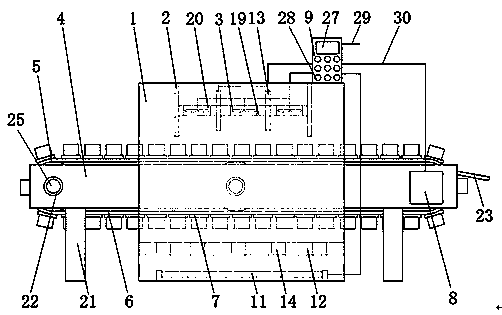

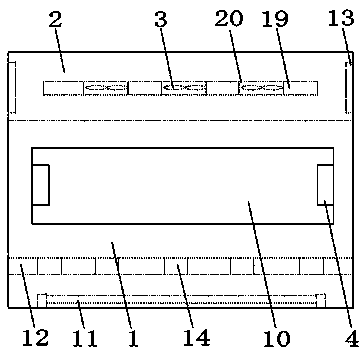

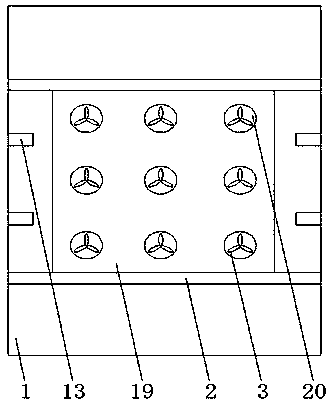

[0034] as attached Figure 1-7 As shown in the figure, a fully automatic tempering processing equipment for track transmission chain rail joints, including a tempering furnace 1, a partition 2, a fan 3, a beam 4, a transmission roller 5, a transmission belt 6, a load plate 7, a motor 8 and a controller 9 It is characterized in that: the opposite sides of the tempering furnace 1 are provided with inlets and outlets 10 through the tempering furnace 1, a heating pipe 11 with a horizontal structure is arranged at the inner bottom of the tempering furnace 1, and on the inner wall 18 at the top of the tempering furnace 1 The second heating pipe 13 of the vertical structure is provided, and the second heating pipe 13 is arranged on the inner wall 18 of the tempering furnace 1 between the partition plate 2 and the partition plate 2, and the flow from the inlet and outlet 10 on the tempering furnace 1 can be reduced by the partition plate 2 Heat, so that the heat in the tempering furna...

Embodiment 2

[0048] as attached Figure 8-11 As shown in the figure, a fully automatic tempering processing equipment for track transmission chain rail joints, including a tempering furnace 1, a partition 2, a fan 3, a beam 4, a transmission roller 5, a transmission belt 6, a load plate 7, a motor 8 and a controller 9 It is characterized in that: the opposite sides of the tempering furnace 1 are provided with inlets and outlets 10 through the tempering furnace 1, a heating pipe 11 with a horizontal structure is arranged at the inner bottom of the tempering furnace 1, and on the inner wall 18 at the top of the tempering furnace 1 The second heating pipe 13 of the vertical structure is provided, and the second heating pipe 13 is arranged on the inner wall 18 of the tempering furnace 1 between the partition plate 2 and the partition plate 2, and the flow from the inlet and outlet 10 on the tempering furnace 1 can be reduced by the partition plate 2 Heat, so that the heat in the tempering furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com