Keyhole sewing machine

A sewing machine and buttonhole technology, which is applied to sewing machine components, control devices for sewing machines, sewing equipment, etc., can solve problems such as hindering threading operations, and achieve the effect of improving the quality of buttonhole stitches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 3

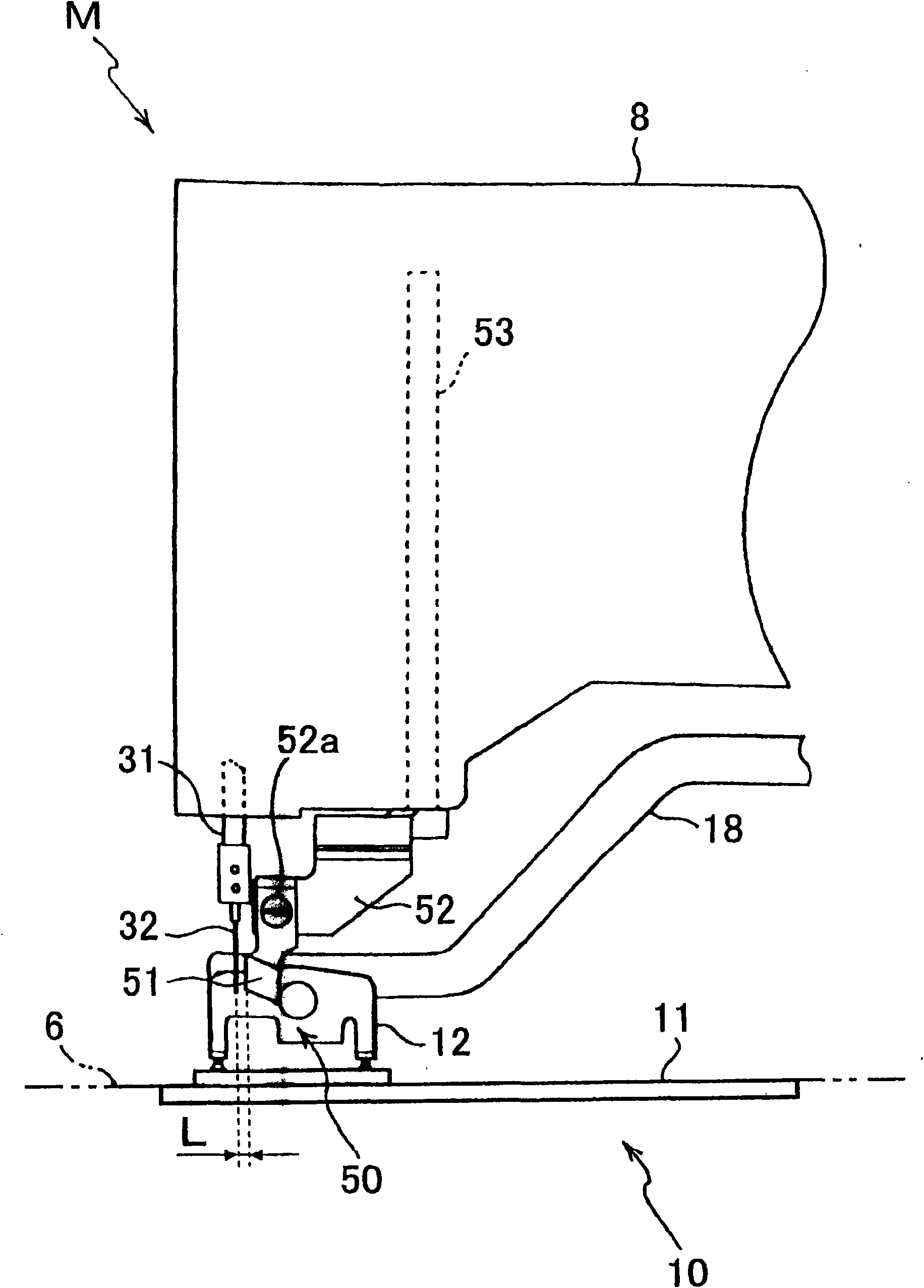

[0195] The buttonhole sewing machine M includes a cutter 51 movable in the front-rear direction. Modification 3 facilitates the threading work of passing the needle thread 33 through the needle 32 by moving the cutter 51 in the front-rear direction.

[0196] Modified buttonhole sewing machine M includes Figure 24 Operation panel 4 shown. As an operation unit, the operation panel 4 includes a threading key 111 (corresponding to an avoidance instruction unit), a selection key 113, a minus key 120, a plus key 121, an input key 122, and a reset key 123 (corresponding to a return instruction unit). As a display unit, the operation panel 4 includes LEDs (Light Emitting Diodes) 112 , 114 to 117 and an image display unit 119 . The operation panel 4 includes a notification buzzer 124 (corresponding to a notification unit).

[0197] The operator operates the threading key 111 when carrying out the threading work of passing the needle thread 33 through the needle 32 . The LED 112 li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com