Method for decreasing basic error of pressure sensor

A pressure sensor, basic error technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problem that the basic error of the pressure sensor cannot be reduced, and achieve the effect of improving the basic measurement accuracy, simple method, and reducing the basic error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

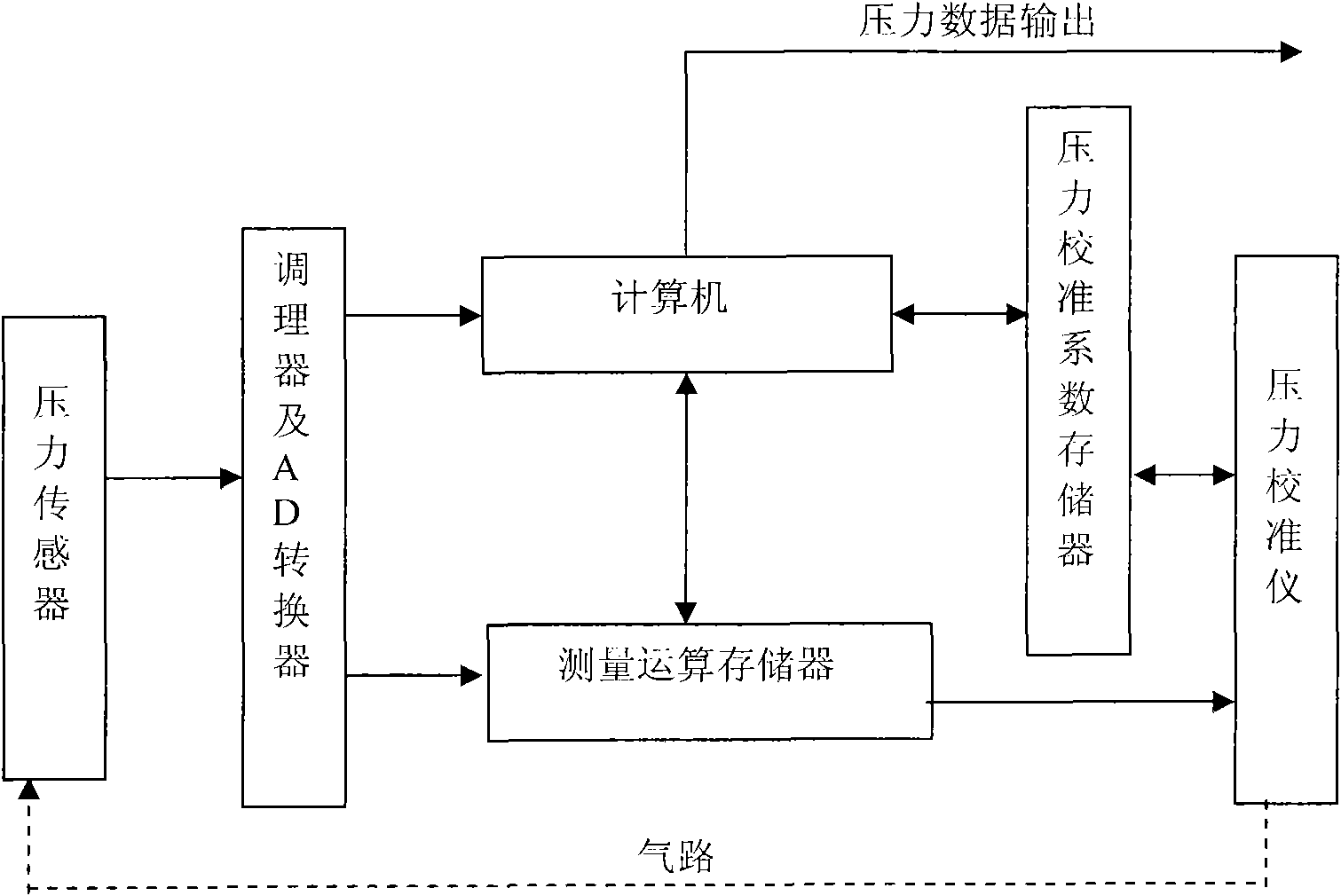

Image

Examples

Embodiment 1

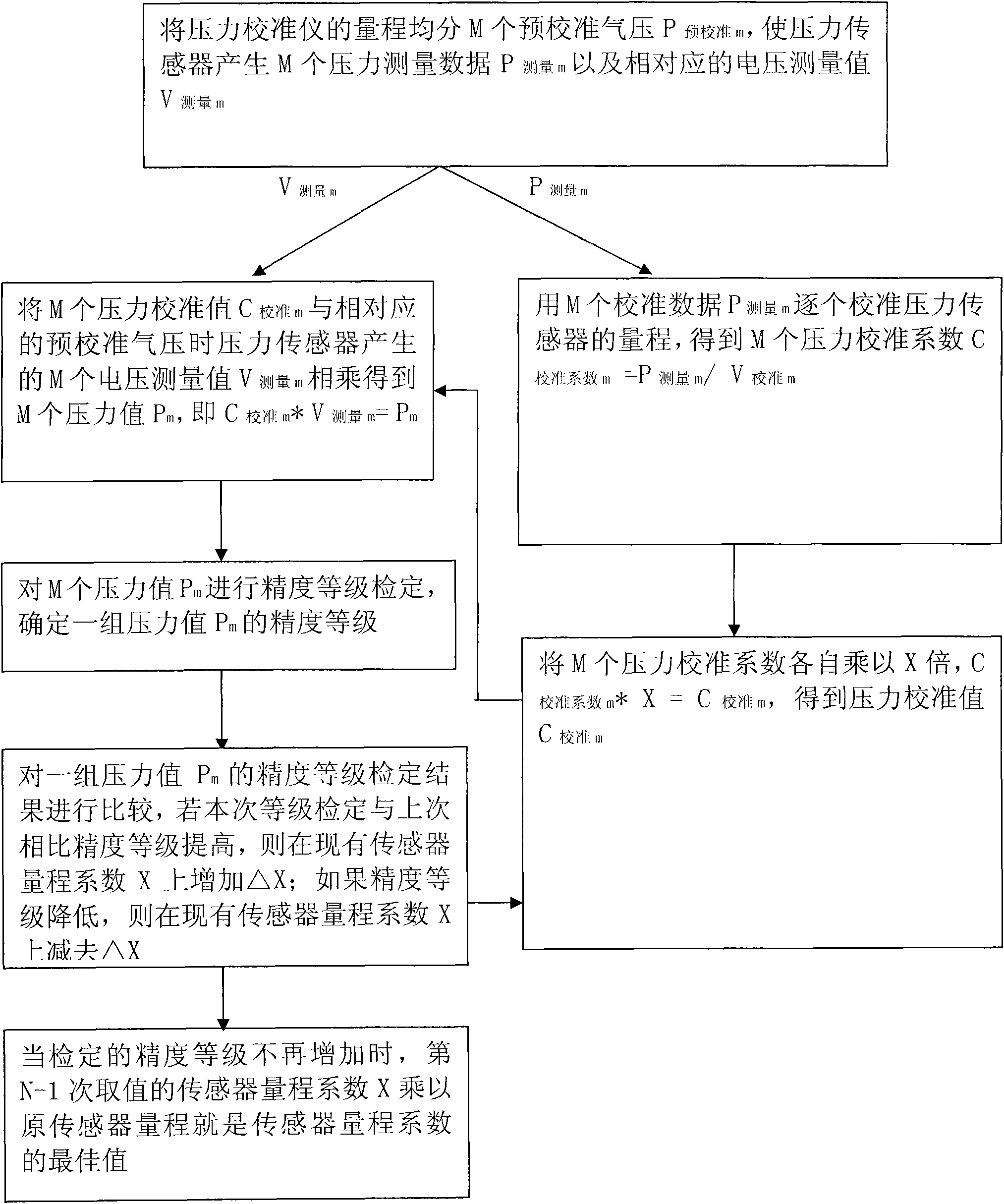

[0019] Such as figure 2 Shown, the present invention comprises the following steps:

[0020] 1. Select the range of the pressure calibrator = the range of the pressure sensor = 10KPa, and divide the range of the pressure calibrator into 10 {P 预校准1 ,...,P 预校准10} Pre-calibrated pressure is applied to the pressure sensor, adjust the output of the pressure calibrator so that the pressure sensor produces 10 pressure measurement data {P 测量1 ,...P 测量10} and the corresponding voltage measurement {V 测量1 ,...V 测量10}, and respectively store 10 pressure data and 10 voltage measurement values according to the order of measurement.

[0021] 2. Put 10 {P 测量1 ,...P 测量10} As the data used for calibration, input to the pressure calibrator one by one in sequence, start the pressure calibrator again to apply to the pressure sensor, use 10 calibration data {P 测量1 ,...,P 测量10} Calibrate the range of the pressure sensor one by one to get 10 pressure calibration coefficients {C 校准系数1 ,.....

Embodiment 2

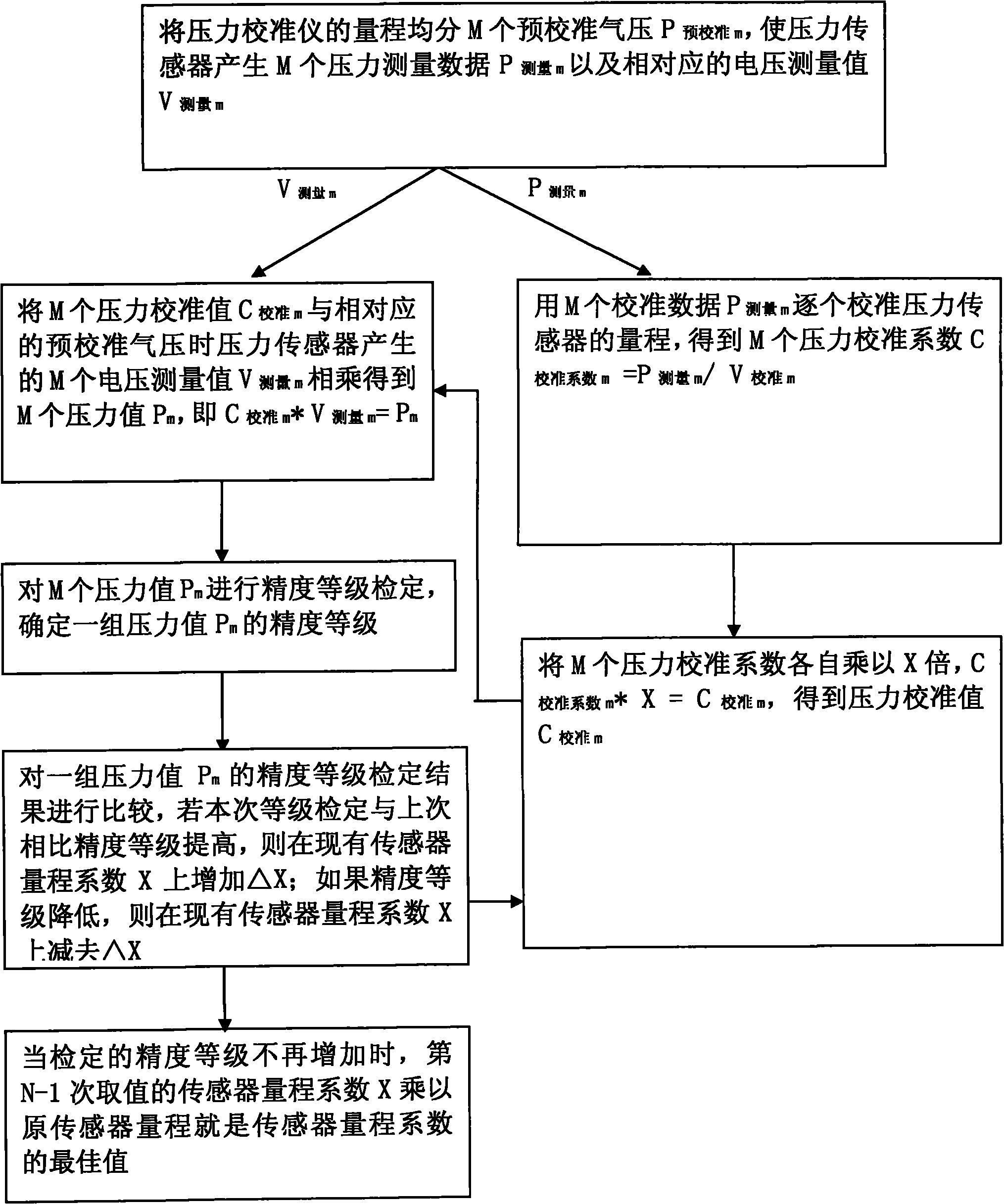

[0028] Such as figure 2 Shown, the present invention comprises the following steps:

[0029] 1. Select the range of the pressure calibrator = the range of the pressure sensor = 2MPa, and divide the range of the pressure calibrator into 200 {P 预校准1 ,...,P 预校准200}The pre-calibrated air pressure is applied to the pressure sensor, and the output of the pressure calibrator is adjusted so that the pressure sensor produces 200 pressure measurement data{P 测量1 ,...,P 测量200} and the corresponding voltage measurement {V 测量1 ,...,V 测量200}, and respectively store 200 pressure data and 200 voltage measurement values according to the order of measurement.

[0030] 2. Put 200 {P 测量1 ,...,P 测量200} As the data used for calibration, input to the pressure calibrator one by one in sequence, start the pressure calibrator again to apply to the pressure sensor, use 200 calibration data {P 测量1 ,...,P 测量200} Calibrate the range of the pressure sensor one by one to get 200 pressure calibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com