Preparation method and application thereof of chromatography packed column of rodlike nano mesoporous molecular sieve material

A nano-mesoporous and molecular sieve technology, applied in the field of chromatographic columns, can solve the problems of chromatographic column filling difficulties, increased pressure, increased back pressure, etc., and achieve the effects of uniform, accurate and controllable structure, efficient separation, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of packed column: 50mg SBA-15 rod filler, add 100μL water, 500uμL methanol, 50uL [3-(2-aminoethyl)aminopropyl]trimethoxysilane, stir the suspension with nitrogen gas for 6h and let it stand overnight. Discard the supernatant, wash with water until neutral; re-suspend with 200 μL of methanol; fill it into a 75 μm capillary column by pressure packing method to prepare a capillary electrochromatography packed column.

Embodiment 2

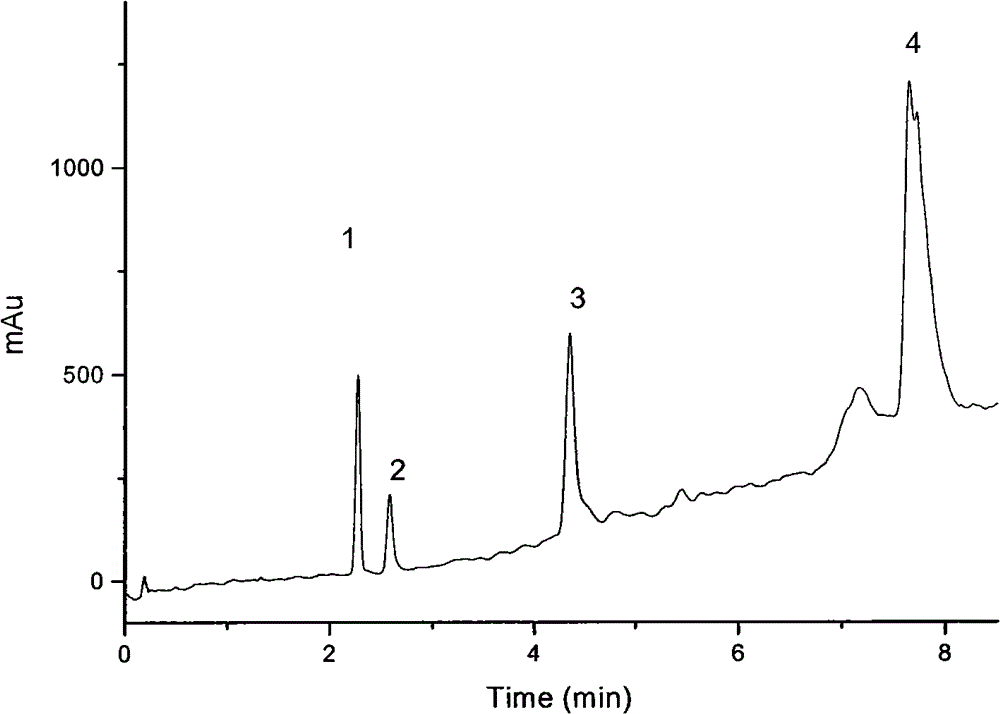

[0042]Preparation of packed column: Add 50mg SBA-15 rod filler, add 50μL water, 500uμL methanol, 50uL 3-aminopropyltrimethoxysilane, pass nitrogen gas into the suspension and stir the suspension for 7h, then let it stand overnight, discard the supernatant, wash with water until Neutral; re-suspended with 200 μL of methanol; electropacked into a 75 μm capillary column to prepare a packed column for capillary electrochromatography. figure 1 Four organic acids were separated for the bond and the [3-(2-aminoethyl)aminopropyl]trimethoxysilane SBF-15 packing.

Embodiment 3

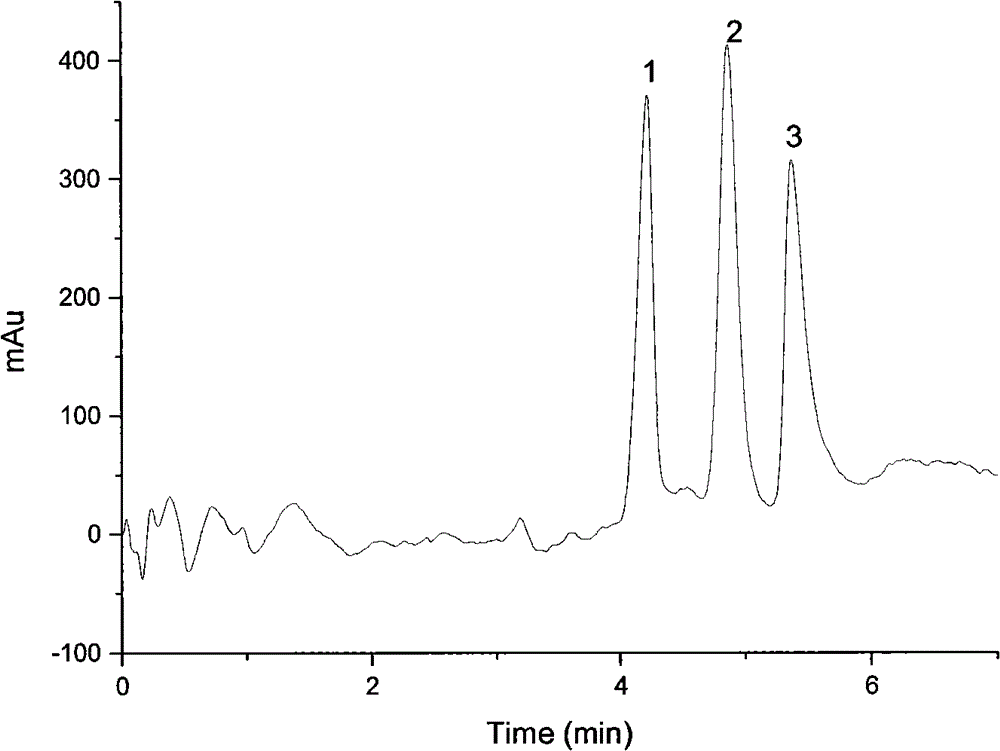

[0044] Preparation of packed column: 50mg SBA-15 rod filler, add 200μL water, 200μL methanol, 10uL [3-(2-aminoethyl)aminopropyl]trimethoxysilane, stir the suspension for 7h with nitrogen gas and let stand overnight , discard the supernatant, wash with water until neutral; re-suspend with 200 μL of methanol; fill it into a 75 μm capillary column by pressure packing method to prepare a capillary electrochromatography packed column. figure 2 Separation of three organic acids for 3-aminopropyltrimethoxysilane SBF-15 packing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com